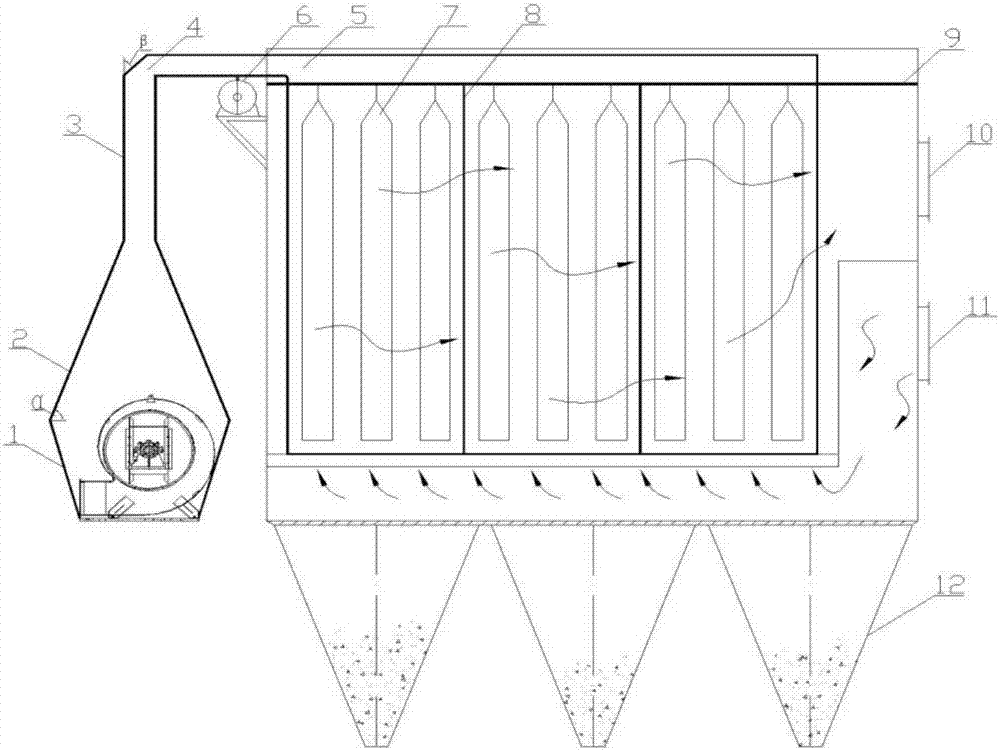

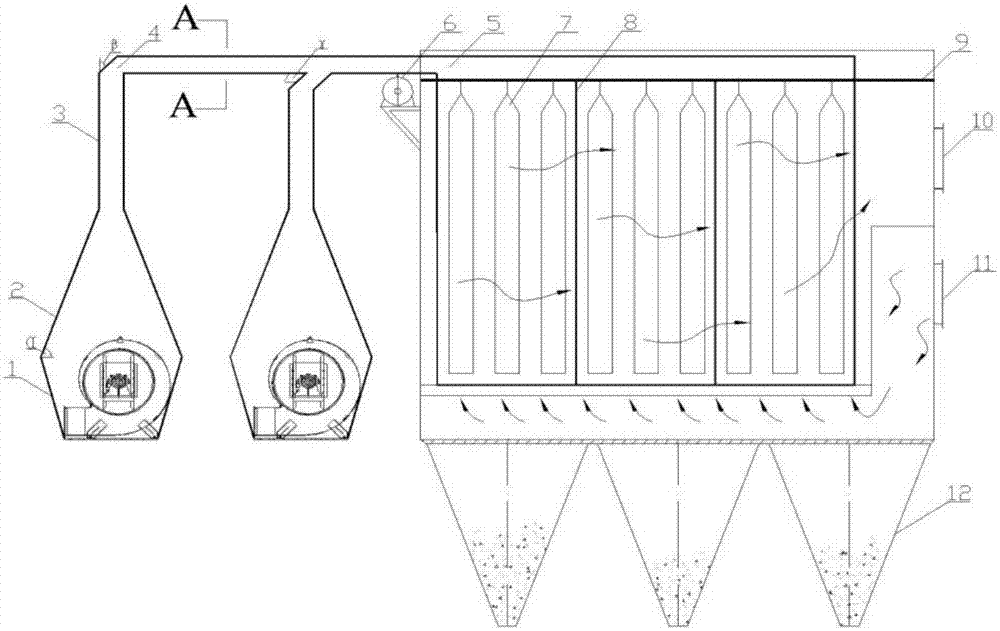

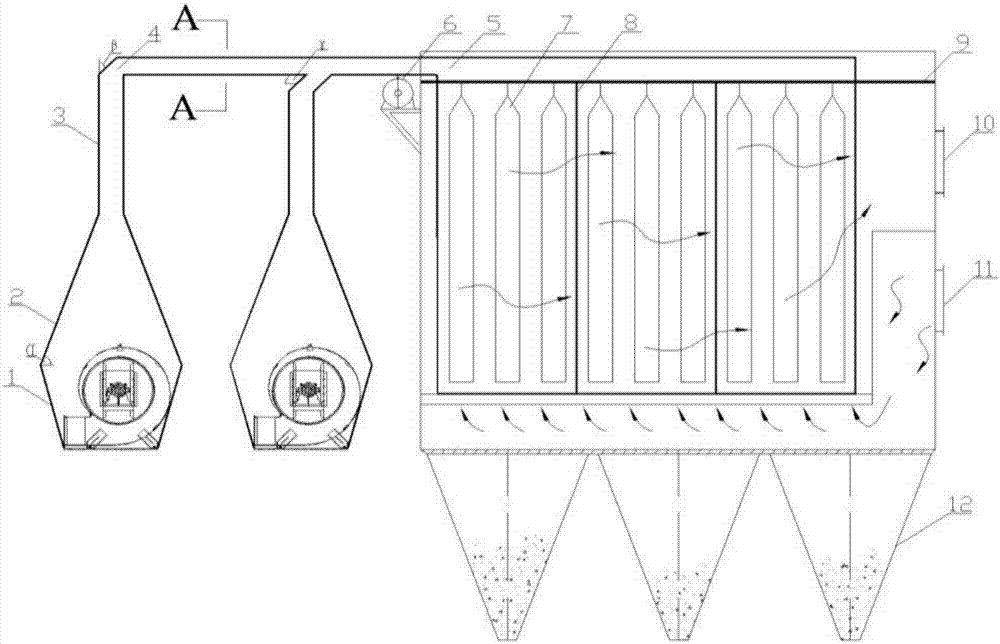

A bag filter fan noise collection and utilization system

A bag filter and noise technology, applied in the field of bag filter fan noise collection and utilization system, to achieve good dust filtering effect, broad development space and market prospects, and reduce the number of cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the amount of waste gas q of a known cement mill v =6120m 3 / h, dust concentration ρ=50g / m 3 , gas temperature 100°C. According to the national standard, the emission of dust in this area is 150mg / m N 3. If the emission of exhaust gas reaches the standard, it is necessary to first select the cyclone dust collector as the primary dust collection device, and select the bag filter as the secondary dust collection device. The required nominal filtration area is 110㎡; cylinder diameter: 2530mm; total body height: 6030mm; filtration wind speed: 1.0-1.5m; processing air volume: 6600-9900m 3 ; Filtration area: 1 ~ 2m / min; one round of cleaning time (cleaning time + cleaning interval) is 50min; processing efficiency: 99%. Under the condition that the processing air volume and filtering wind speed remain unchanged, the new technology is adopted to collect and utilize the fan noise, which can effectively extend the cleaning interval of 30 minutes; at the same t...

Embodiment 2

[0018] Example 2: The dust collector used in a cement factory in Sichuan is a bag type dust removal system, and the flue gas volume q v =10000m 3 / h, the initial dust concentration is ρ=6g / m 3 , the cloth is polyester fleece filter material, the temperature of the gas entering the dust collector does not exceed 393K, and the pressure loss is 1200Pa. Filtration speed is 2m / min; filter bag area: 90㎡; filter bag diameter: 200mm; filter bag length: 4m; one round of cleaning time (cleaning time + cleaning interval) is 65min; The waste discharge standard (DB 51-186-93) must make the treatment efficiency of the dust collector reach more than 95%. Under the condition that the processing air volume and filtering wind speed are kept unchanged, the new technology is adopted to collect and utilize the fan noise, which can increase the dust removal efficiency of the dust collector to 99%, extend the cleaning time to 110min, and reduce the vibration of the motor (15~20 times / s) vibration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com