Punching progressive die system for machining leaf spring countersink of heavy truck

A technology of progressive die and punching punch, which is applied in the field of punching progressive die system for heavy truck leaf spring counterbore processing, can solve the problems of high energy consumption, complicated process, low production efficiency, etc., to save production cost, facilitate Operation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

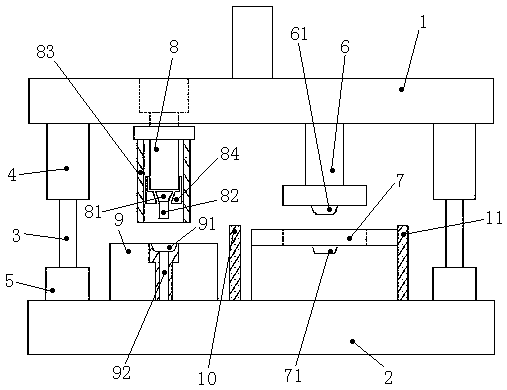

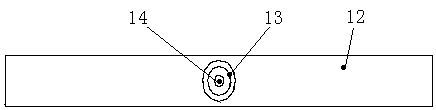

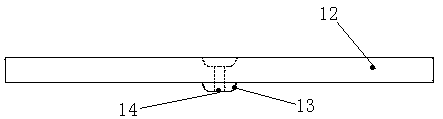

[0021] See attached figure 1 , attached figure 2 and attached image 3 The present invention is further described.

[0022] A punching progressive die system for heavy-duty vehicle leaf spring counterbore processing, characterized in that the structure includes an upper die plate (1) and a lower die plate (2) connected by a guide post (3), and the upper die plate (1 ) is provided with a bulging punch (6) at one end, and a punching punch handle (8) at the other end, and the punching punch handle (8) is connected with a punching punch (81); the lower template (2) is connected with the bulging punch The position corresponding to the mold (6) is provided with a bulging die (7), and the position corresponding to the punching punch (81) on the lower template (2) is provided with a punching die (9); the bulging punch (6 ) is provided with a bulging punch head (61), and the bulging die (7) is provided with a counterbore forming cavity (71) matched with the bulging punch head (61);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com