Grinding wheel placing disc for electric tools

A technology for electric tools and disc placement, which is applied to the device for fixing the grinding wheel, manufacturing tools, metal processing equipment, etc. It can solve the problems of inability to protect the grinding wheel, inconvenient take-out, and large space occupation, and achieves ingenious structural design and easy removal. , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

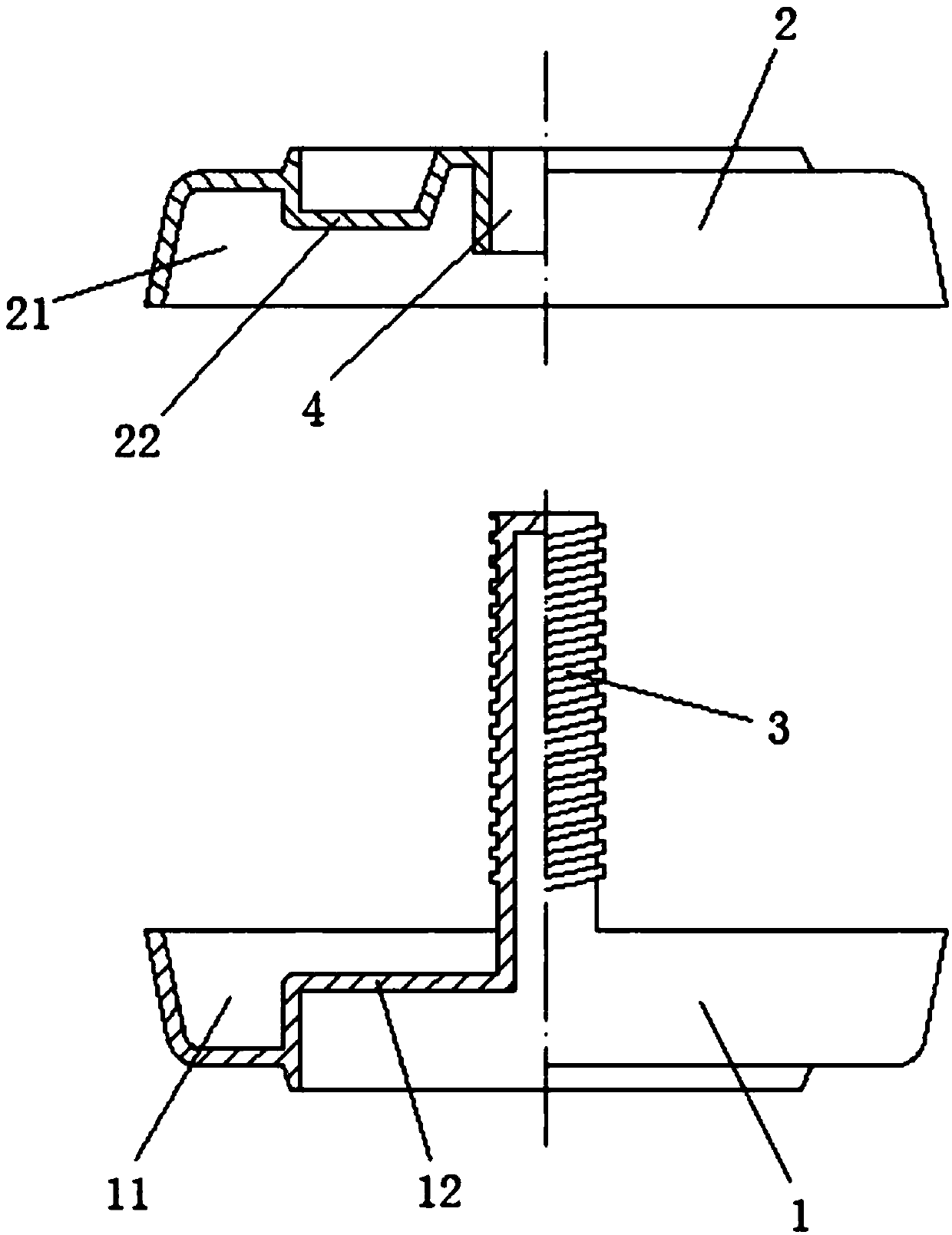

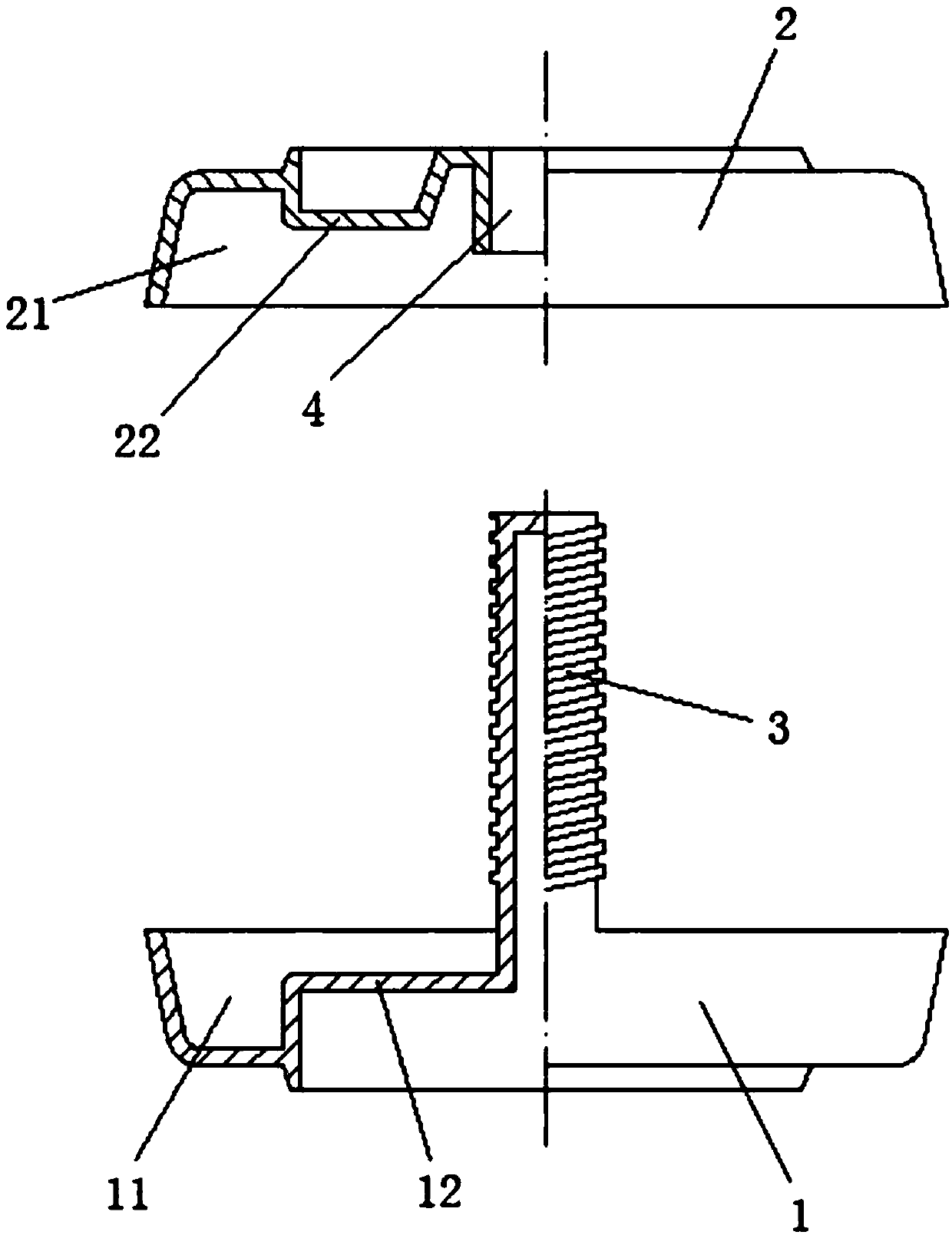

[0015] See figure 1 , the present invention comprises accommodating disc body 1 and pressing disc body 2; Described accommodating disc body 1 has the accommodation groove 11 that is used to place emery wheel; Coaxial support platform 12; the support platform 12 protrudes to the outside of the tank 11; the center of the support platform 12 is provided with a stud 3 perpendicular to the bottom surface of the tank and extending to the outside of the tank 11; the pressing The disc body 2 has a coaxial groove 21; the notch of the groove 21 is opposite to the notch of the container 11; The platform 22 ; the center of the pressing disc body 2 is provided with a threaded through hole 4 threadedly matched with the stud 3 .

[0016] The supporting platform 12 is located in the cavity 11; the pressing platform 22 is located in the groove 21; the containing plate 1 and the pressing plate 2 contact each other to form a closed space between the containing plate 11 and the groove 21.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com