Dust removing device for open pit mine

A technology for dust removal devices and open-pit mines, applied in safety devices, dust prevention, mining equipment, etc., can solve problems such as insecurity, motors are easy to enter dust or water, etc., to increase the layout space, increase the dust removal coverage area, and increase the spray volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

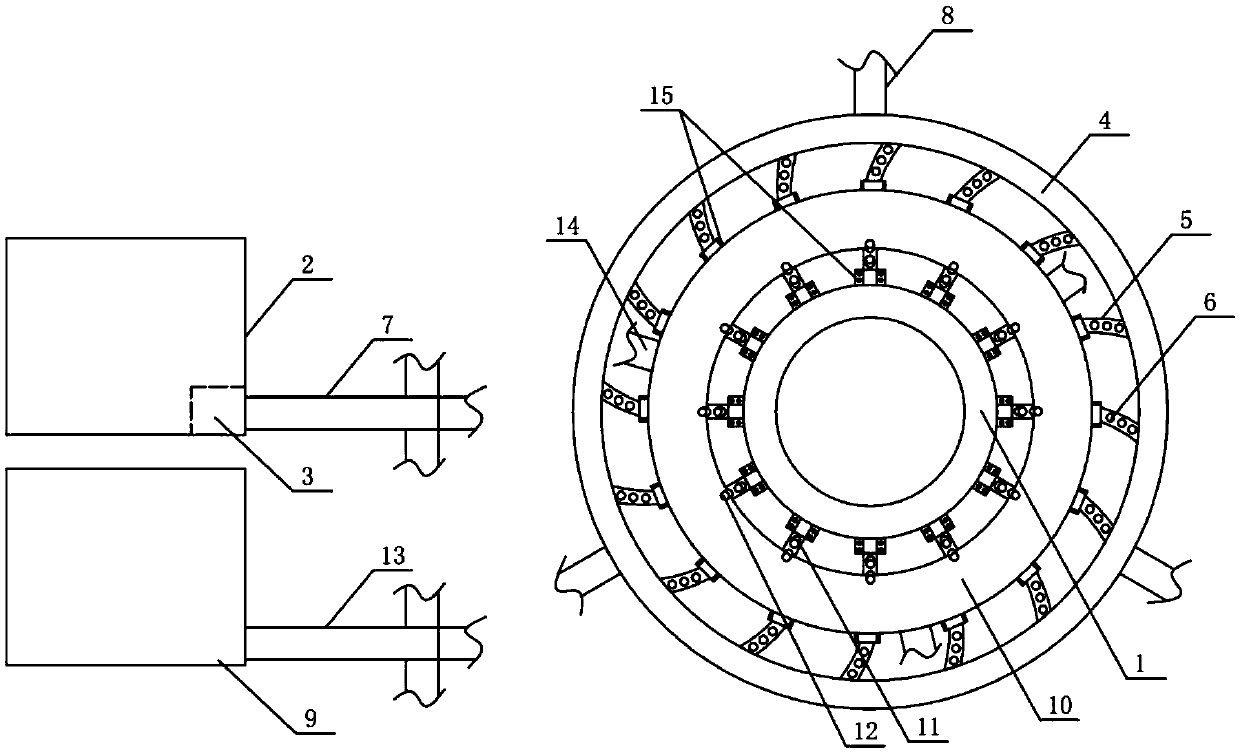

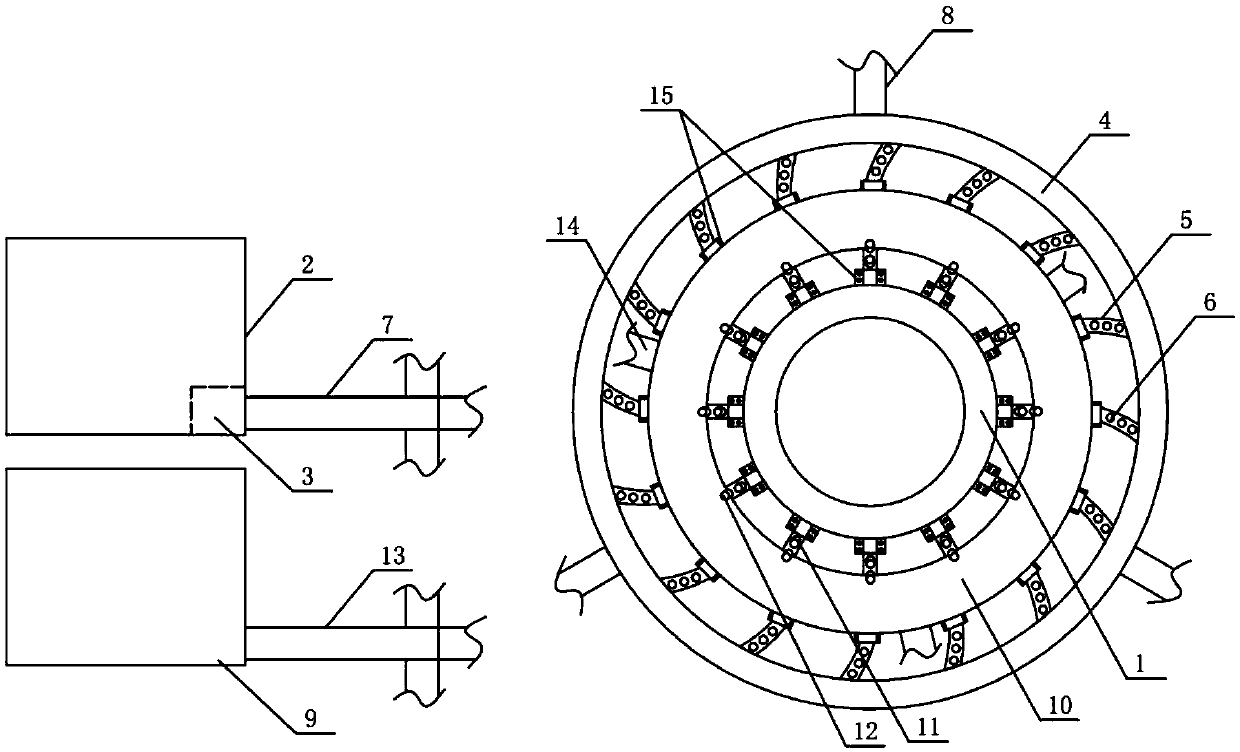

[0027] Such as figure 1 , the present invention is a planar structure, which sequentially includes a spray device, an air injection device and a support seat 1 from the outside to the inside, and the support seat 1 is an annular structure;

[0028] The spraying device includes a water tank 2, a water pump 3, a water supply pipe and a high-pressure water distribution main pipe 4. The water pump 3 is located in the water tank 2. The water pump 3 communicates with the high-pressure water distribution main pipe 4 through the water supply pipe. The high-pressure water distribution main pipe 4 is a ring structure. Sixteen high-pressure water distribution branch pipes 5 are connected to the inner side of the distribution main pipe 4. The high-pressure water distribution branch pipes 5 are located between the high-pressure water distribution main pipe 4 and the air injection device. Three spray heads 6 are evenly arranged on each high-pressure water distribution branch pipe 5. The wat...

Embodiment 2

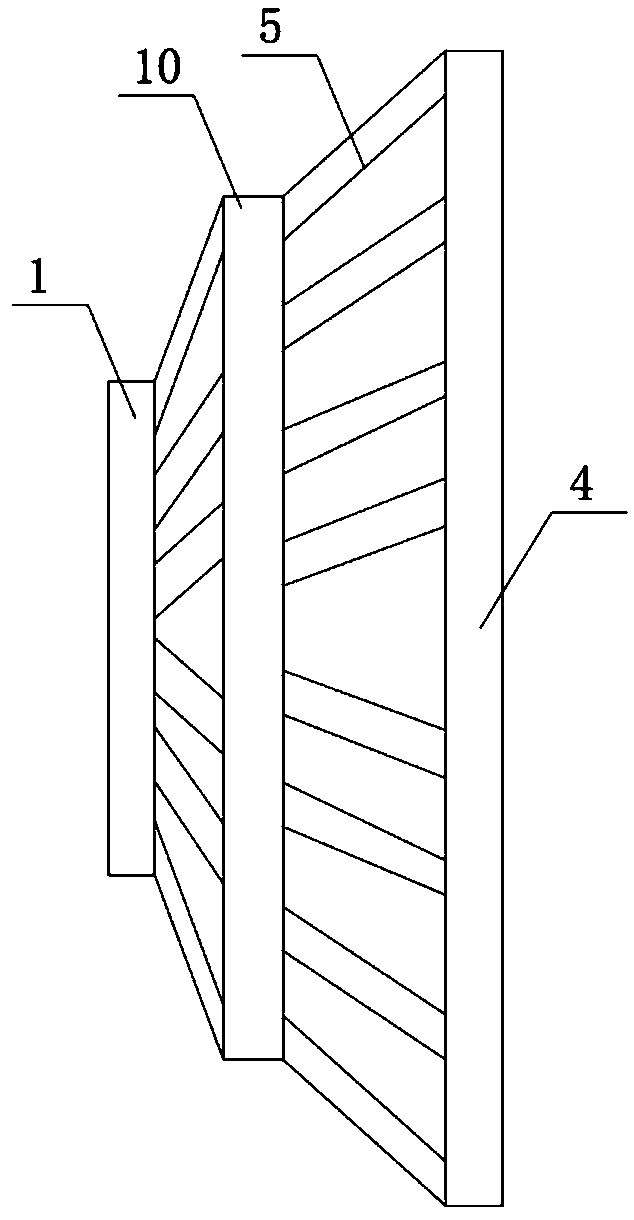

[0033] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as figure 2 As shown, the dust removal device disclosed by the present invention is a frustum-shaped structure, the high-pressure water distribution branch pipe 5 is a straight pipe, the area of the circle where the support seat 1 is located, the area of the circle where the high-pressure air distribution main pipe 10 is located, and the area of the circle where the high-pressure water distribution main pipe 4 is located increase in turn.

[0034] In this embodiment, the dedusting device is designed as a truncated cone structure, which can increase the overlapping area of the spray and air injection, and further enhance the spray area of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com