Two-gear pure electric vehicle transmission gear shifting mechanism and shifting mechanism method

A pure electric vehicle and shifting mechanism technology, which is applied in mechanical equipment, transmission control, components with teeth, etc. problems such as the comfort of shifting and stopping of the car, to achieve the effect of reducing assembly costs, reducing procurement costs, and reducing shifting setbacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

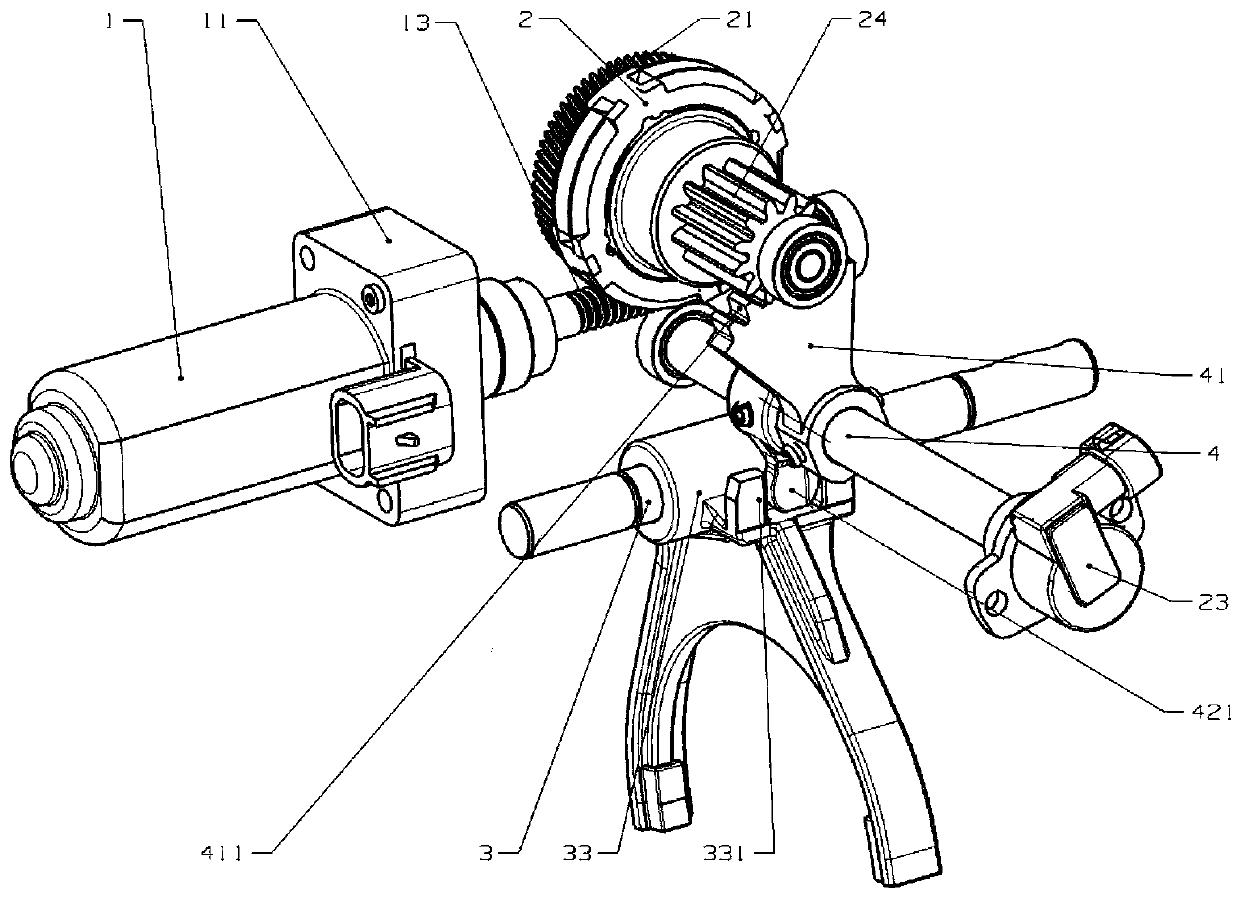

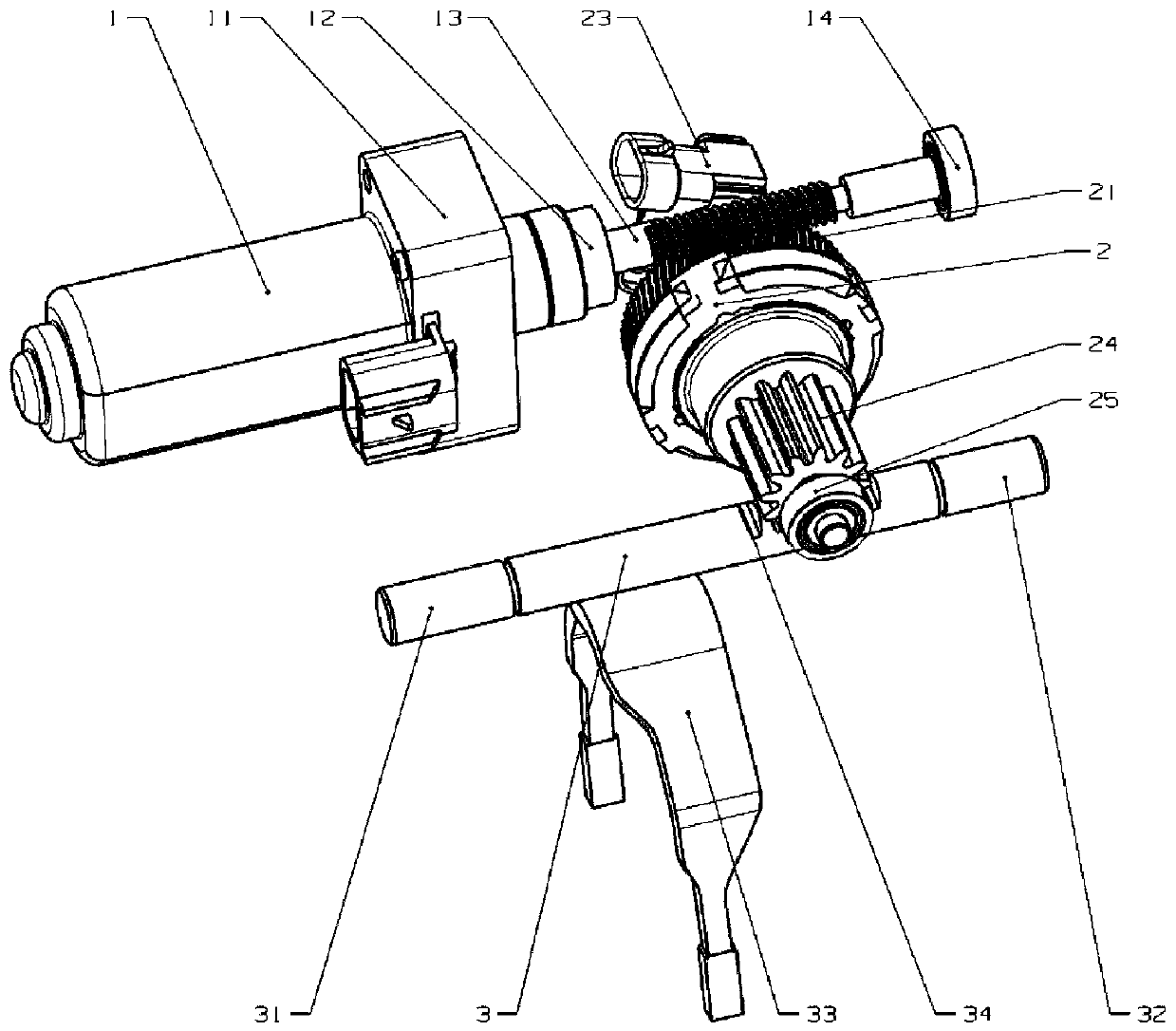

[0030] Such as Figure 2 to Figure 5 As shown, the shift mechanism of the two-speed pure electric vehicle transmission disclosed by the present invention includes a motor worm assembly 1 , a torsional shock absorber assembly 2 and a shift fork assembly 3 .

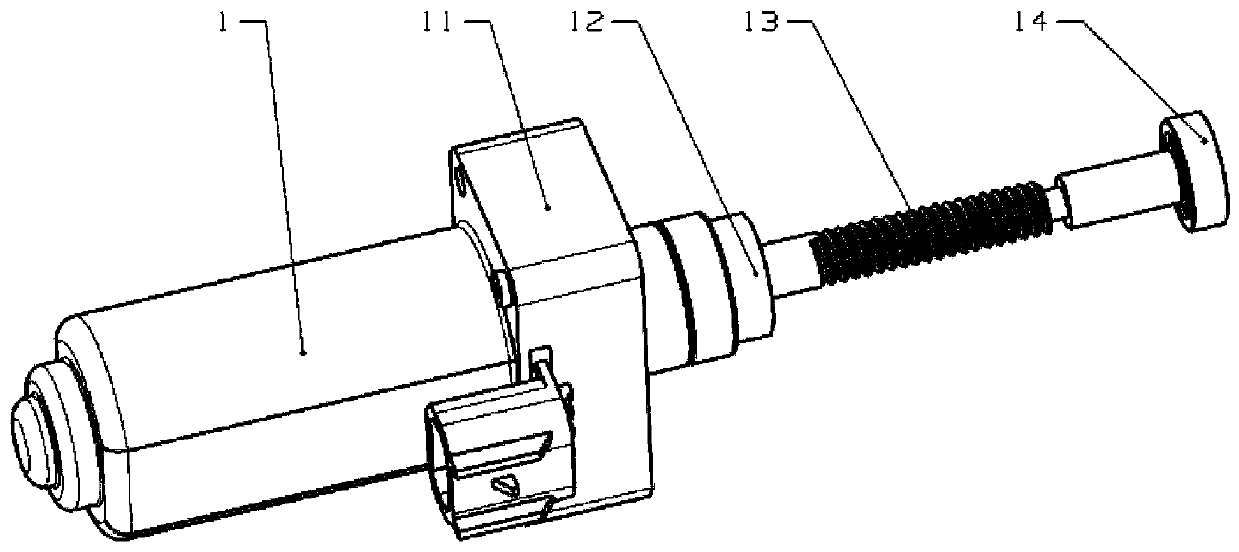

[0031] The motor worm assembly includes a motor 11 , a worm 13 driven by the motor 11 , a left worm bearing 12 and a right worm bearing 14 . The two ends of the total worm 13 of the motor worm are respectively fitted with a left worm bearing 12 and a right worm bearing 14, and the motor worm assembly is fixedly connected to the transmission case through the left worm bearing 12 and the right worm bearing 14.

[0032] One end of the torsional shock absorber assembly 2 is a turbine 21, and the other end is a spur gear 24 coaxial with the turbine 21. An angle sensor 23 is arranged on one side of the turbine 21, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com