Double-FPC turnover automatic bonding mechanism

A flip mechanism and bonding technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of small FPC area, reduced production yield, low alignment stability, etc., to solve the limited installation position and improve equipment stability. , the effect of reducing long-term dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

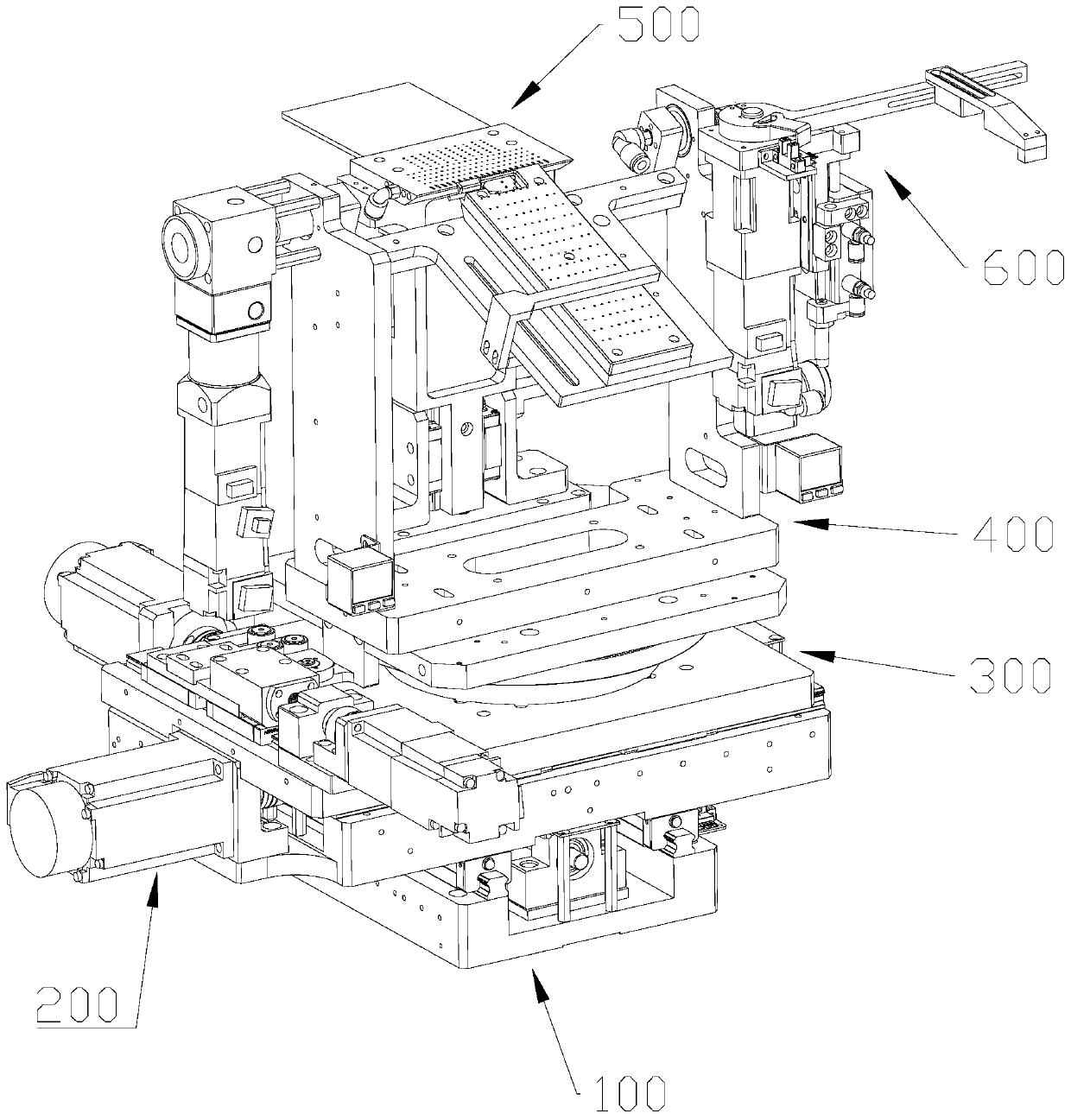

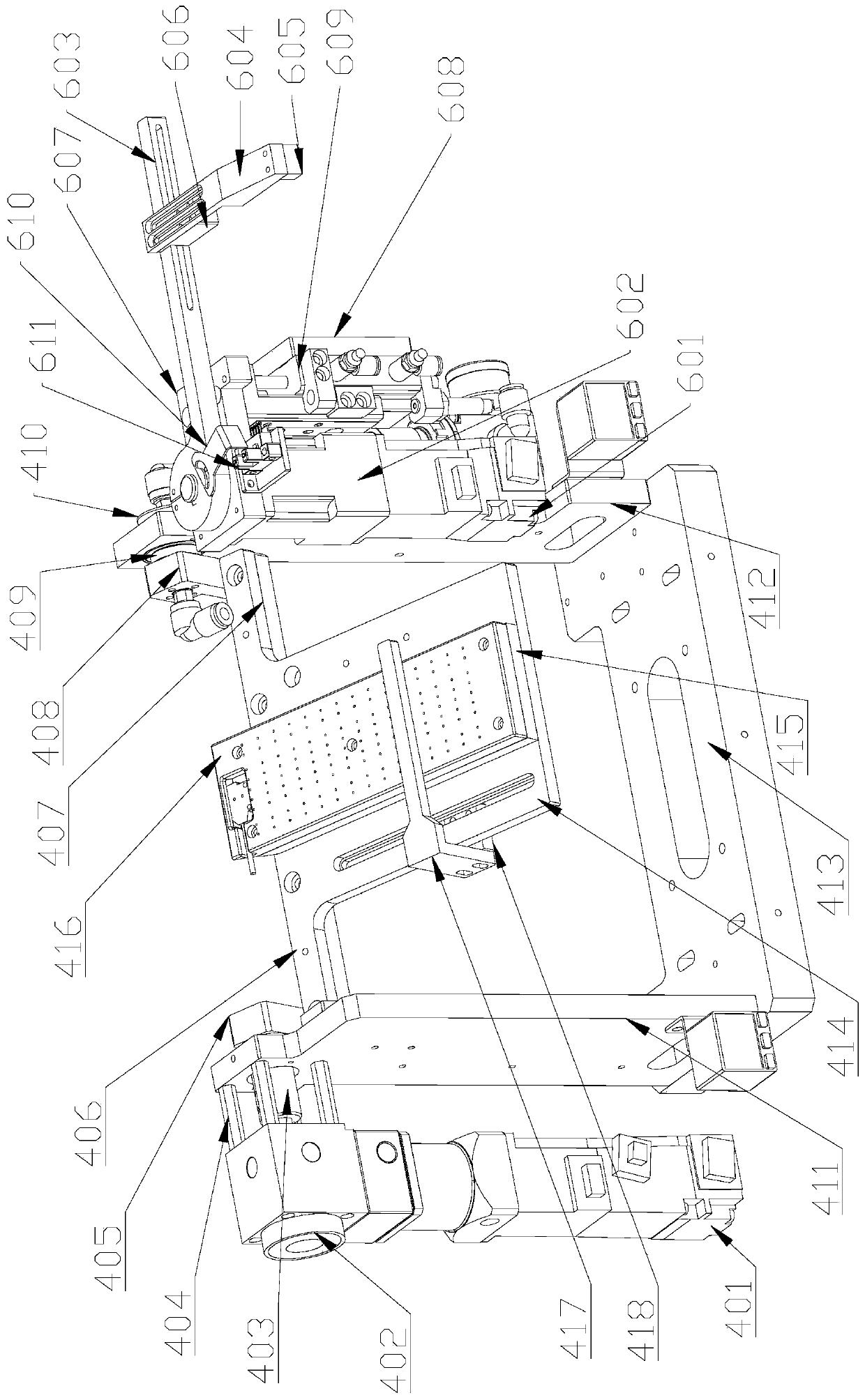

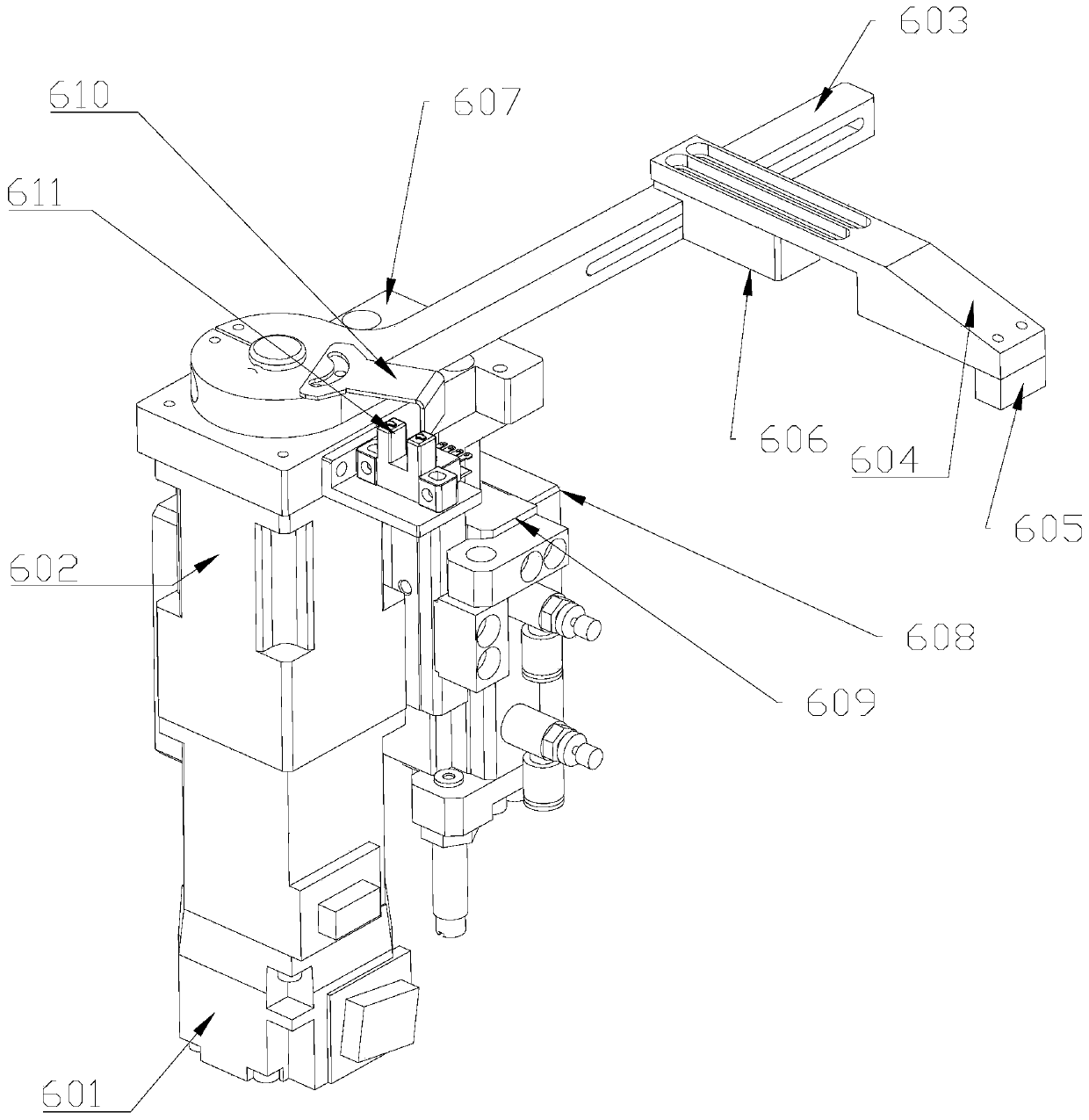

[0027] Such as figure 1 As shown, the double FPC flipping automatic bonding mechanism of the present invention includes a platform Y-axis mechanism 100, a platform X-axis mechanism 200, a platform Q-axis mechanism 300, a supporting backrest mechanism 500, a TP flipping mechanism 400 and an FPC auxiliary pressing rod mechanism 600, The FPC auxiliary pressing rod mechanism 600 is installed on the TP turning mechanism 400, and the TP turning mechanism 400 and the support back mechanism 500 are respectively installed on the platform Q-axis mechanism 300 and are on the platform Q-axis. The platform Q-axis mechanism 300 is mounted on the platform X-axis mechanism 200 and reciprocates along the X-axis driven by the platform X-axis mechanism 200. The platform The X-axis mechanism 200 is installed on the platform Y-axis mechanism 100 and is driven to reciprocate by the Y-axis mechanism. In the present invention, the supporting backrest mechanism 500 is used to carry the TP FPC, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com