Sample warper

A warping machine and fancy technology, applied in warping machines, textiles, papermaking, tool manufacturing, etc., can solve the problem that the silk thread can no longer place the warp rods correctly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

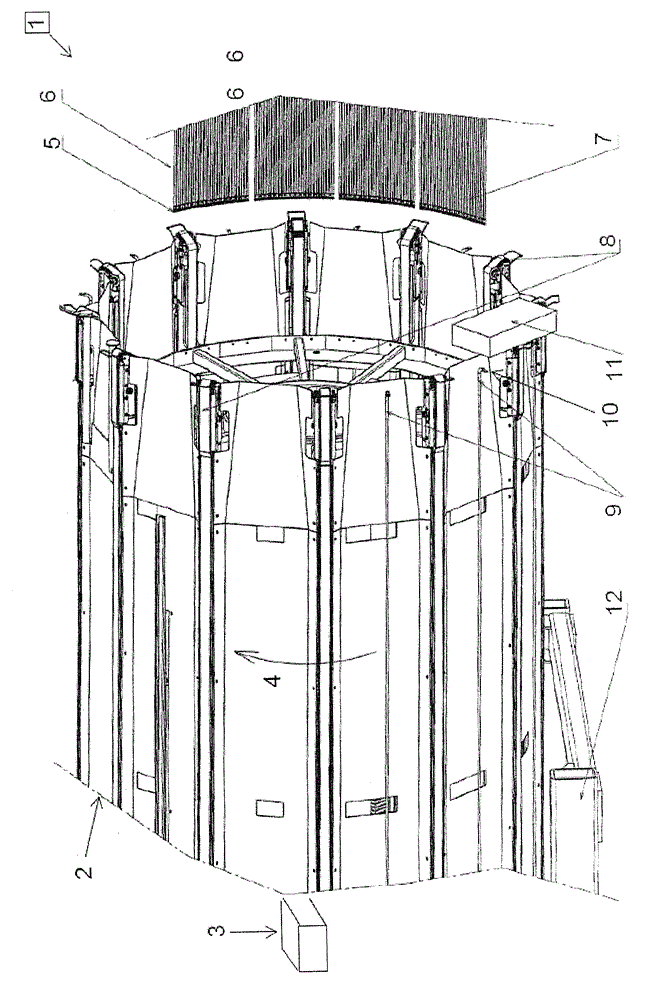

[0024] The effect warping machine 1 has a warping cylinder 2 connected to a schematically shown winding drive 3 . During winding, the winding drive 3 is able to turn the warping cylinder 2 in the direction indicated by the arrow 4 .

[0025] A number of bobbins are mounted on a creel (not shown). In this exemplary embodiment, up to 128 bobbins can be mounted on the creel.

[0026] The thread is drawn from each bobbin and guided through the thread guide eyelet 5 of the thread guide 6 . All yarn guides 6 together form an anti-lapping device 7 .

[0027] The yarn guide 6 can be moved in such a way that the yarn guide eyelet 5 is guided in the axial direction on the warping cylinder 2 . Therein, the thread guided through the thread guide eyelet 5 is then unwound on a conveyor belt 8 constituting the conveying surface, which moves parallel to the axis of said warping cylinder 2 away from the end at which an anti-lapping device 7 is mounted. If the thread is not unwound on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com