Battery holder

A battery fixing and battery technology, applied in the direction of batteries, battery cover/end cover, battery pack parts, etc., can solve the problem of flexible parts movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

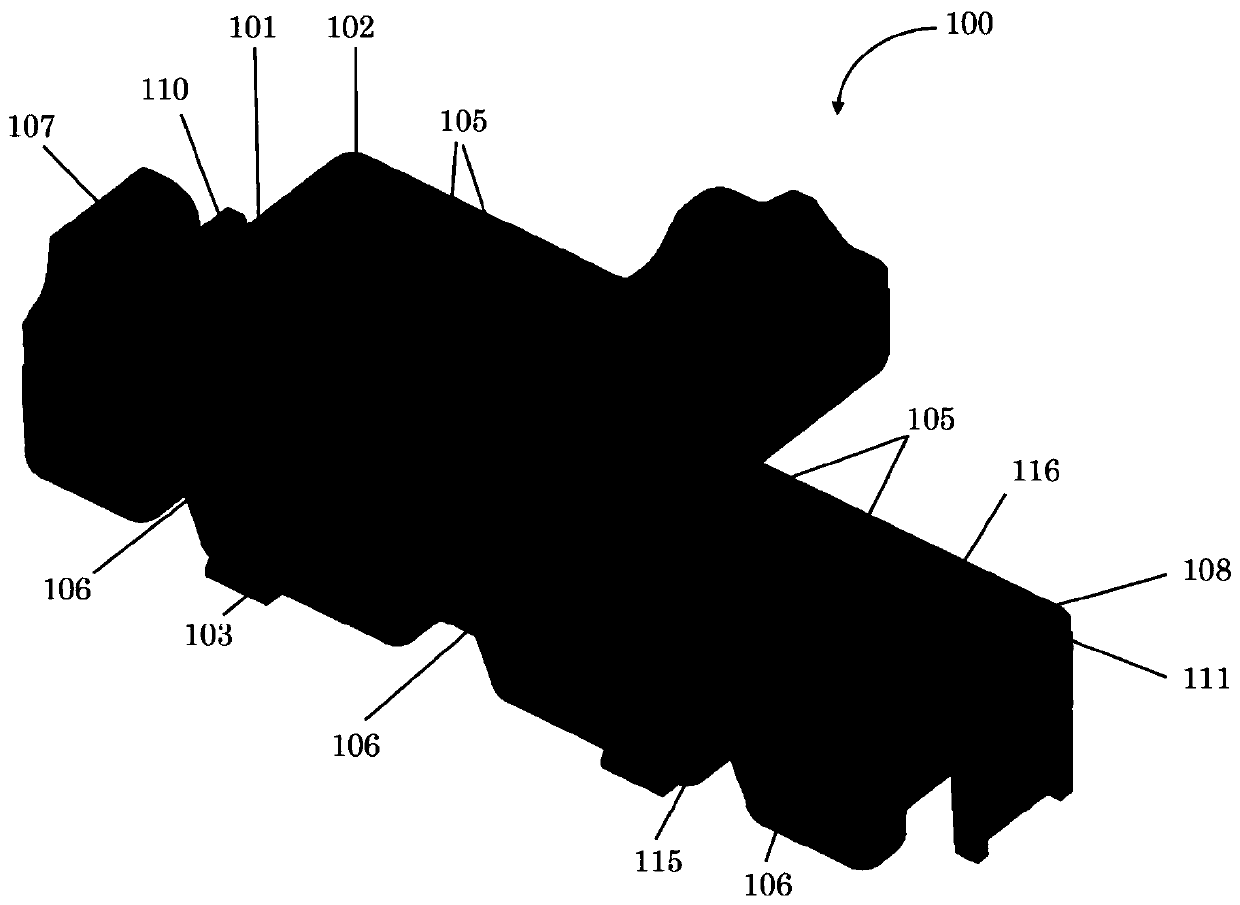

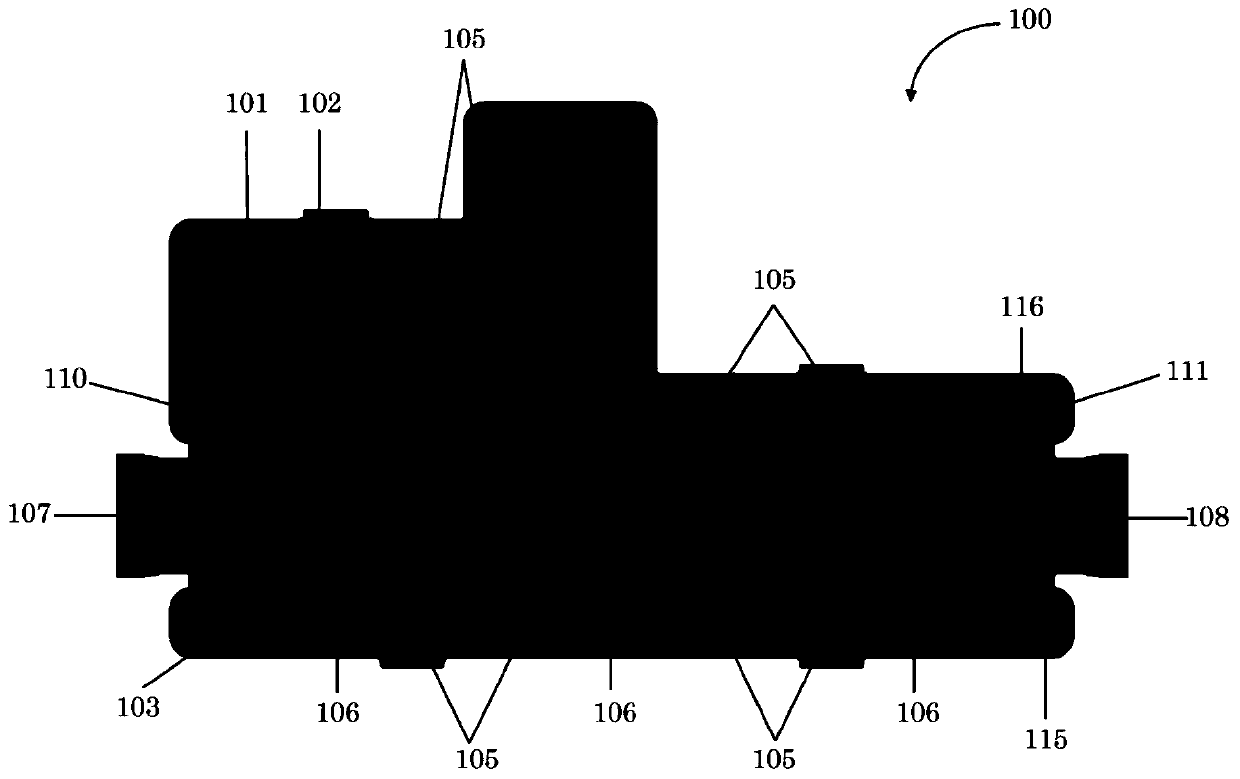

[0028] Figure 1A A perspective view of an interior surface of an exemplary second housing component 100 including a top surface is shown. The inner surface 103 may include a first sub-compartment 101 and a second sub-compartment 102 , wherein the first sub-compartment 101 includes a first end wall 110 , a second end wall 111 , a first side wall 115 and a second side 116 . Figure 1B show Figure 1A A top view of the second housing part 100 shown in .

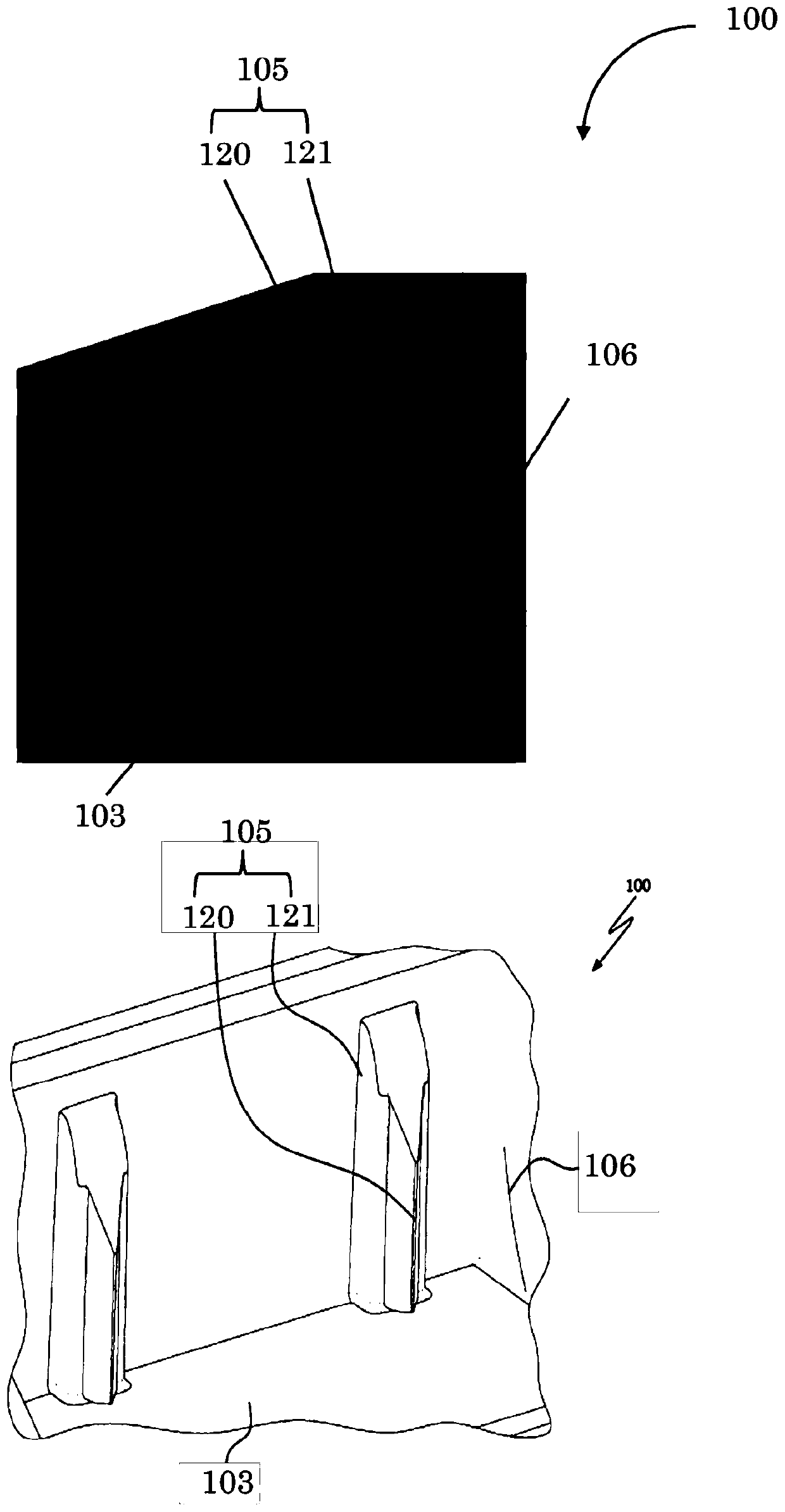

[0029] In one embodiment, the inner surface 103 also includes a plurality of crush ribs 105 on the first and second side walls 115 , 116 . In one embodiment, there may be one crush rib 105 on the inner surface of the first side wall 115 and one crush rib 105 on the inner surface of the second side wall 116 . In another embodiment, the plurality of crush ribs 105 is located on the inner surface of the first side wall 115 and the plurality of crush ribs 105 is located on the inner surface of the second side wall 116 . In an exe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap