Ultrahigh-pressure biological culture device and use method thereof

A technology of biological cultivation and ultra-high pressure, applied in the fields of botany equipment and methods, cultivation, application, etc., can solve the problems of not being applicable to both terrestrial organisms and aquatic organisms cultivation research, and the narrow application range of biological cultivation devices, so as to ensure accurate The effect of high speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: An ultra-high pressure biological cultivation device.

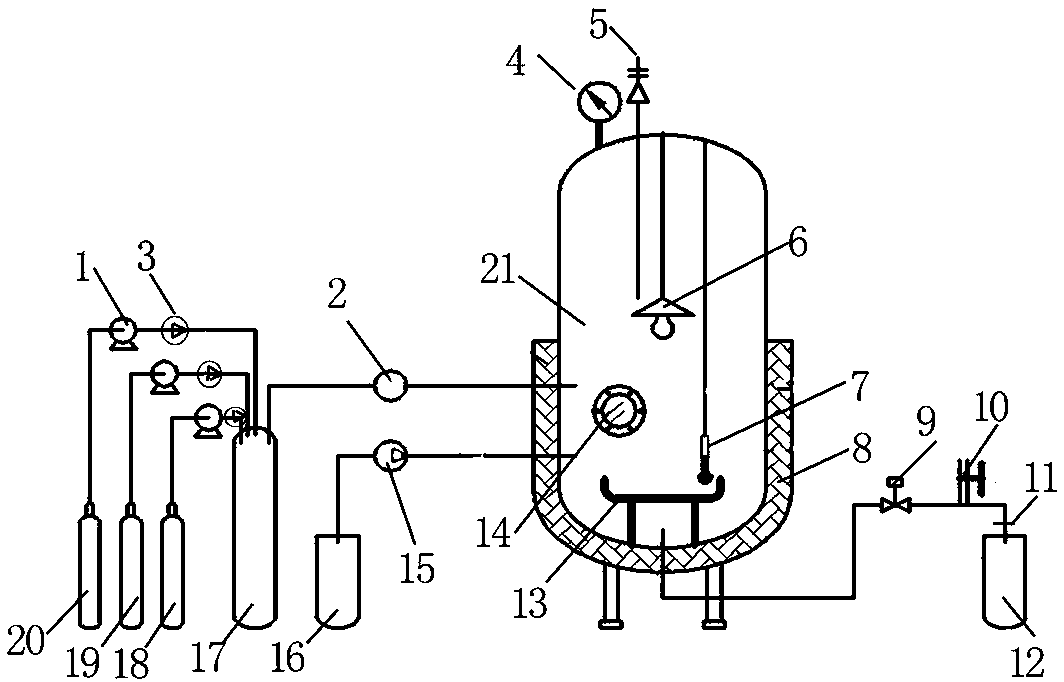

[0061] Such as figure 1 As shown, the present invention provides an ultra-high pressure biological cultivation device, the structure of which includes: three gas storage tanks, a mixing tank 17 , a nutrition tank 16 and a reaction kettle 21 . Wherein each gas storage tank is connected to the mixing tank 17 through pipelines respectively, and a flow detection device 1 and a control valve 3 are arranged on the pipeline of the connecting pipe. The gas flow and send the flow signal to the controller. The gas storage tank is used to transport gas into the mixing tank 17 . In this embodiment, according to the growth needs of experimental organisms, three gas storage tanks are provided, namely an oxygen tank 18 for storing oxygen, a carbon dioxide tank 19 for storing carbon dioxide, and a helium tank 20 for storing helium. Oxygen and carbon dioxide provide the oxygen and carbon dioxide needed for the grow...

Embodiment 2

[0073] Embodiment 2: A method of using an ultra-high pressure biological culture device.

[0074] This embodiment provides a method for cultivating terrestrial organisms using the ultra-high pressure biological cultivation device mentioned in Embodiment 1, which specifically includes the following steps:

[0075] a. Set the ultra-high pressure biological culture device introduced in Example 1.

[0076] b. Open the chamber door 14 of the reaction kettle 21, place the terrestrial organisms to be tested on the biological support 13 and close the chamber door 14.

[0077] c. Set the proportion of gas input into the mixing tank 17 through the controller, control the proportion of oxygen between 0-30%, participate in the oxidation reaction of biological metabolism, control the proportion of carbon dioxide between 0.03-0.1%, and participate in the photosynthesis of plants effect. The controller controls the opening of the control valve 3 so that the gas in the gas storage tank is i...

Embodiment 3

[0085] Embodiment 3: A method of using an ultra-high pressure biological culture device.

[0086] This embodiment provides a method for cultivating aquatic organisms using the ultra-high pressure biological cultivation device mentioned in Embodiment 1. The steps for cultivating aquatic organisms are similar to the steps of the method mentioned in Embodiment 2, the difference is that the embodiment is set. After the cultivation device introduced in 1, add water for pressurization in the mixing tank 17, and mix the gas sent to the mixing tank 17 with the water for pressurization in the mixing tank 17 and send it to the reaction kettle through the pressurization pump 2 21 and fill the cavity of the whole reactor 21. Moreover, after the depressurization is completed, the main liquid discharge valve 9 and the sampling switch are opened in sequence, and the waste liquid sample is collected at the sampling port 10 for analysis and research, and finally the liquid discharge switch 11 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap