Film pasting combination device

A combined device and film sticking technology, applied in the field of film sticking, can solve problems such as the inability to meet the changing curved surface of steel plates, uneven bonding of multiple small arc surfaces, and unbalanced film sticking of two-dimensional film, so as to overcome the easy consumption of tools and overcome The effect of unbalanced section and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

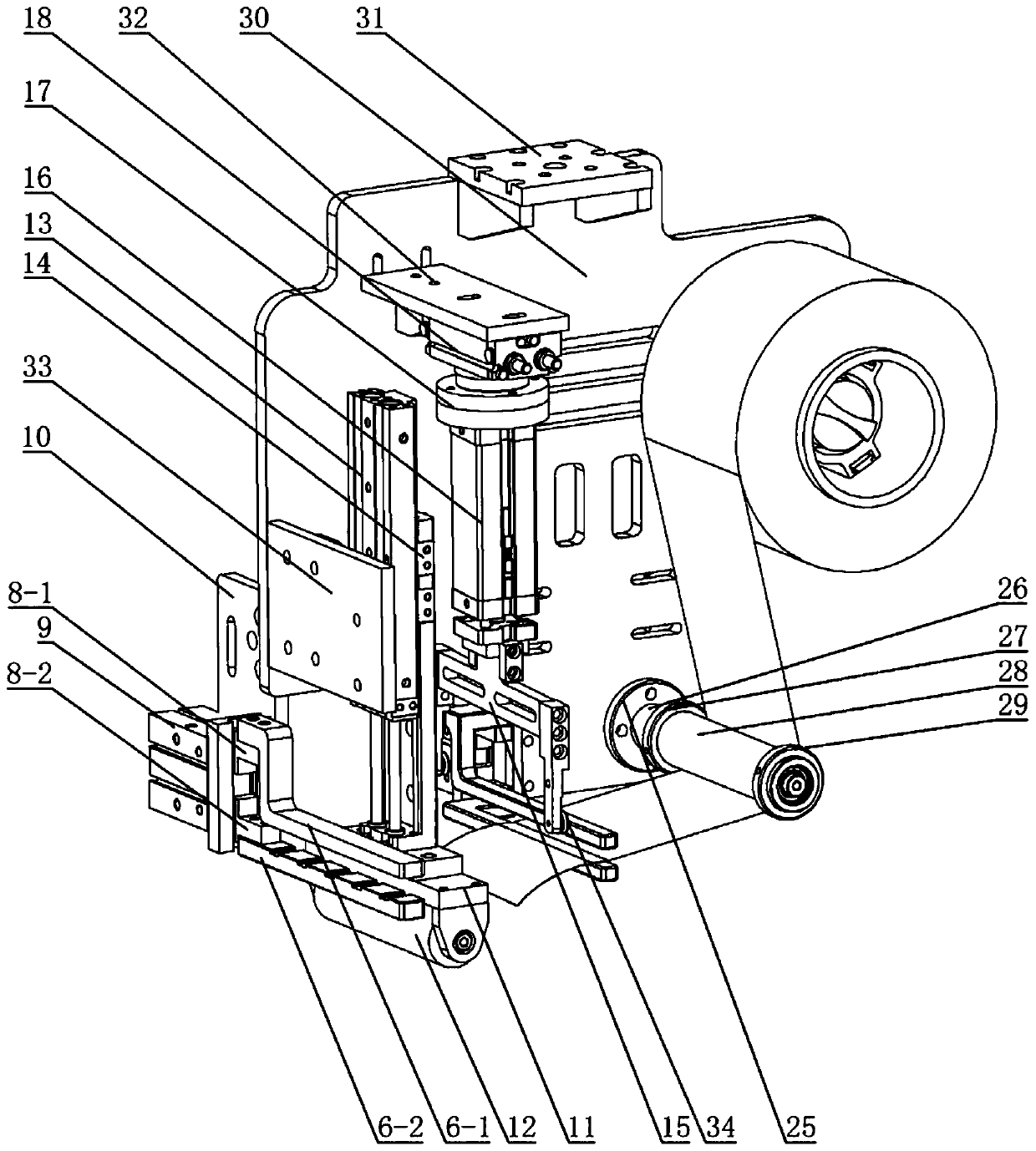

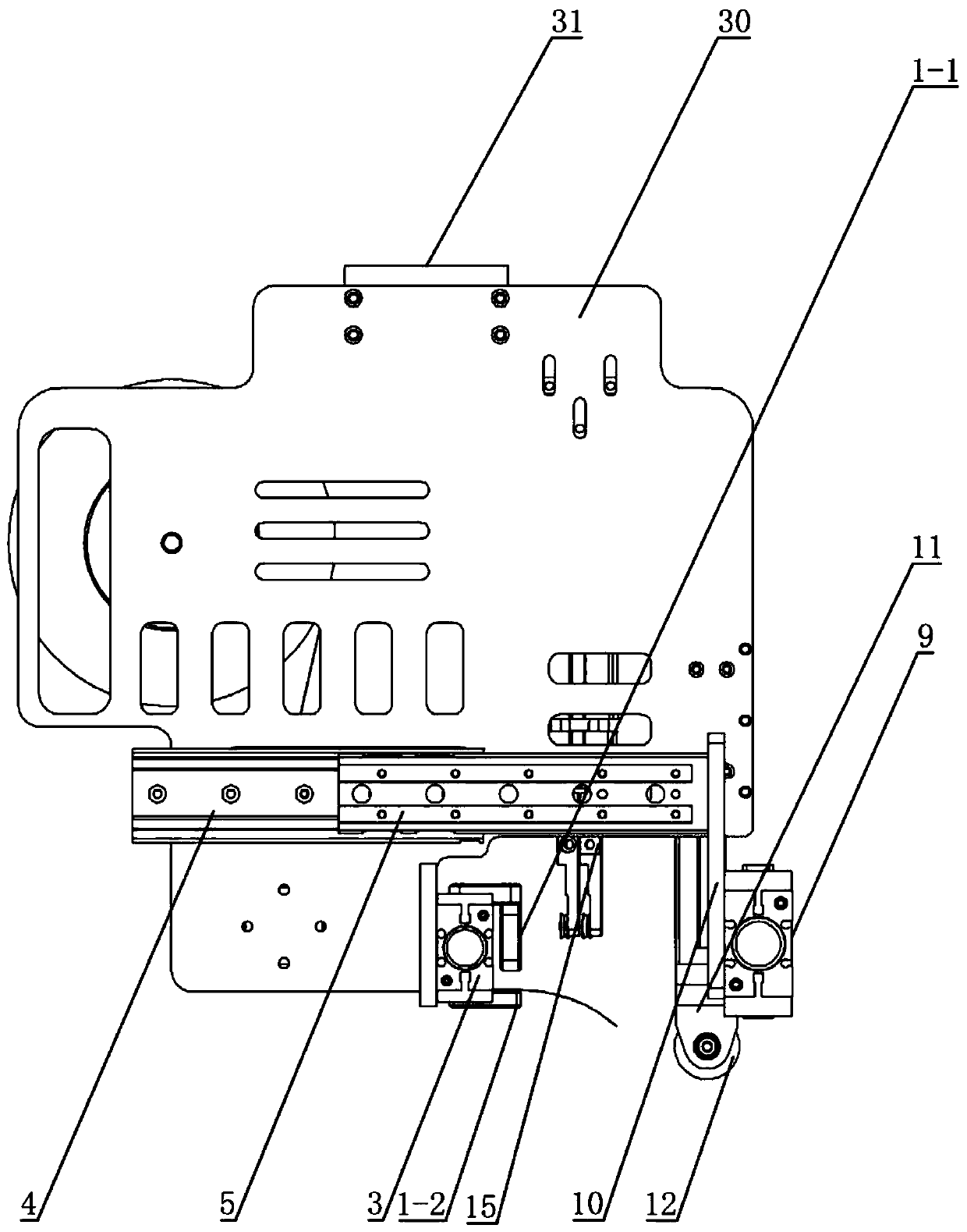

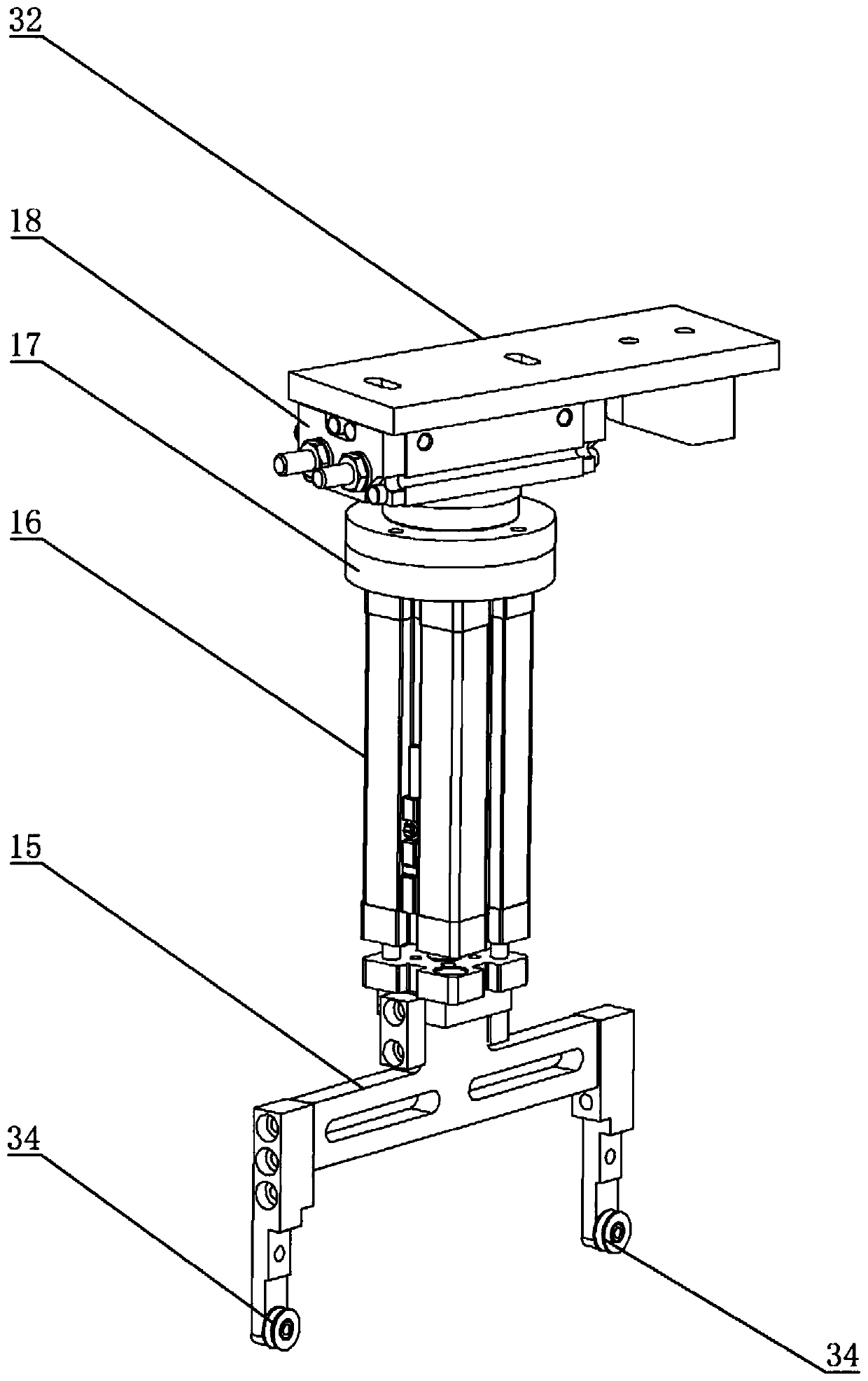

[0024] Example: as attached Figure 1-6 As shown, the film sticking combination device includes a film covering frame 30 and a clamping device, and the clamping device includes a first clamping mechanism and a second clamping mechanism, and the first clamping mechanism and the second clamping mechanism A shaping device is arranged between them, the shaping device includes a pressure applying mechanism and a cutting mechanism, a feeding device is arranged in the feeding direction of the clamping device, and the first clamping mechanism is fixedly arranged on the laminating frame 30, The cutting mechanism is fixedly connected with a first fixed plate 32, and the first fixed plate 32 is fixedly arranged on the laminating frame 30, and the pressure applying mechanism is fixedly connected with a second fixed plate 33, and the second fixed plate 33 is fixedly arranged on the lamination frame 30.

[0025] The first clamping mechanism includes a first main clamp 1-1 and a first auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com