Full-steel radial tire forming machine belt ply feeding frame with material stretching prevention function

A belt layer feeding rack and radial tire technology, applied in the field of tire industry manufacturing, can solve the problems of material stretching, long waiting time, etc., and achieve the effect of extending the effective conveying length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] specific implementation plan

[0058] The present invention is described in detail below in conjunction with accompanying drawing:

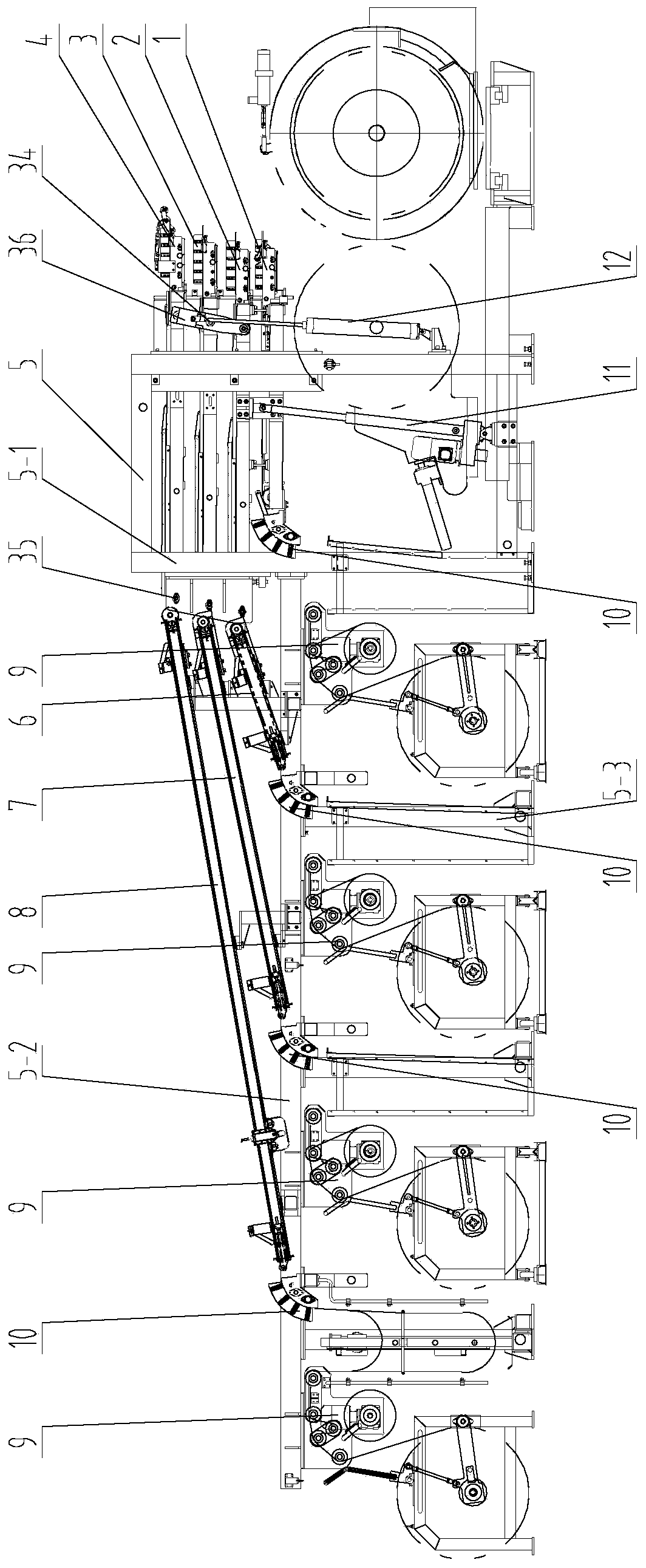

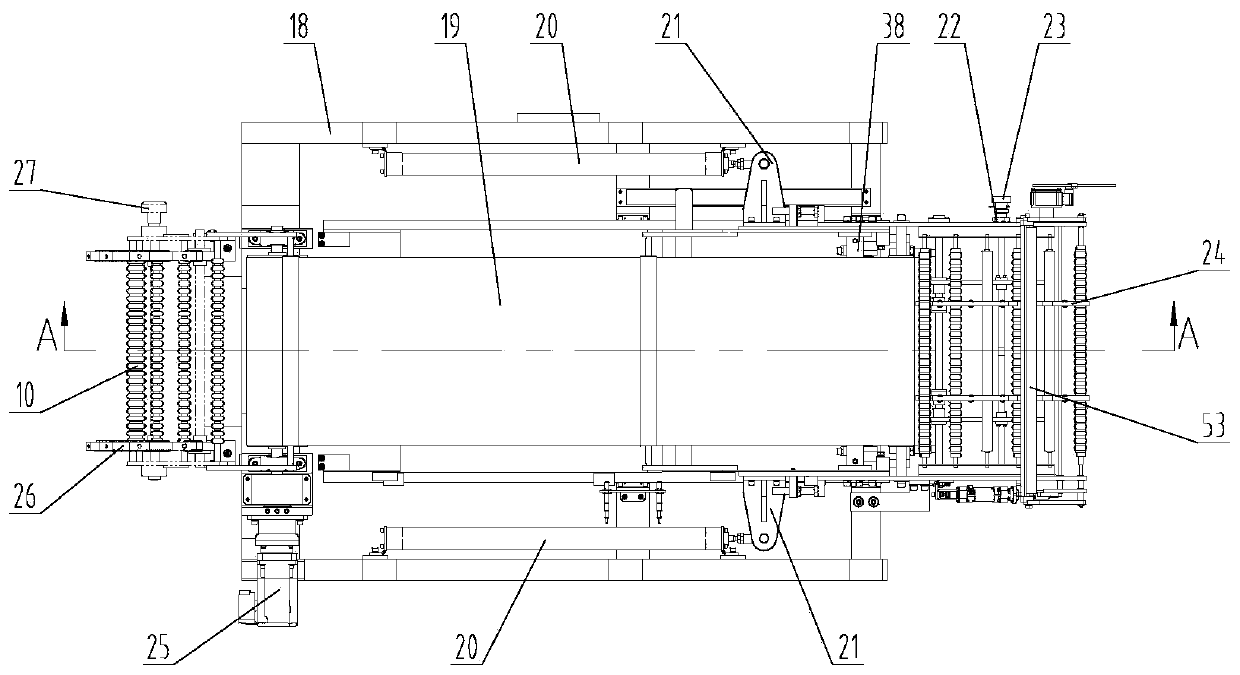

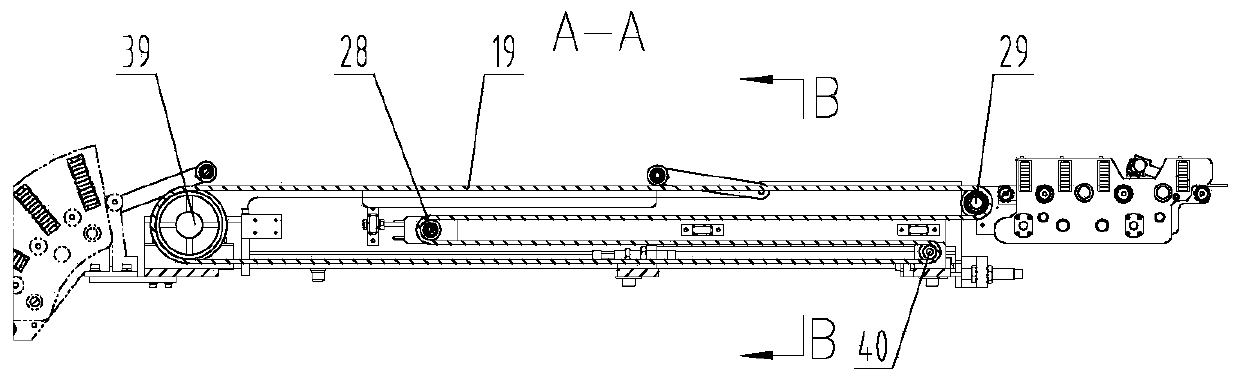

[0059] Such as figure 1 with Figure 5 As shown, the technical solution adopted in the present invention includes a belt layer feeder frame 5, and the belt layer feeder frame 5 includes a main frame 5-1, a crossbeam 5-2 and a column 5-3. The main frame 5-1 of the feed rack frame 5 is equipped with a two-layer lamination template 2, a three-layer lamination template 3 and a four-layer lamination template 4 from bottom to top, and the two-layer lamination template 2, the three-layer lamination template The front ends of the bonding template 3 and the four-layer bonding template 4 are equipped with a first support shaft 34, and a second support shaft 35 is fixedly installed on the main frame 5-1 of the belt layer feeding frame frame 5. The tail ends of the two-layer bonding template 2, the three-layer bonding template 3 and the four-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com