Torsion testing device for shaft class

A technology of torsion testing and shafts, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of affecting the test results, easy to slip, etc., and achieve the effect of good flexibility and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

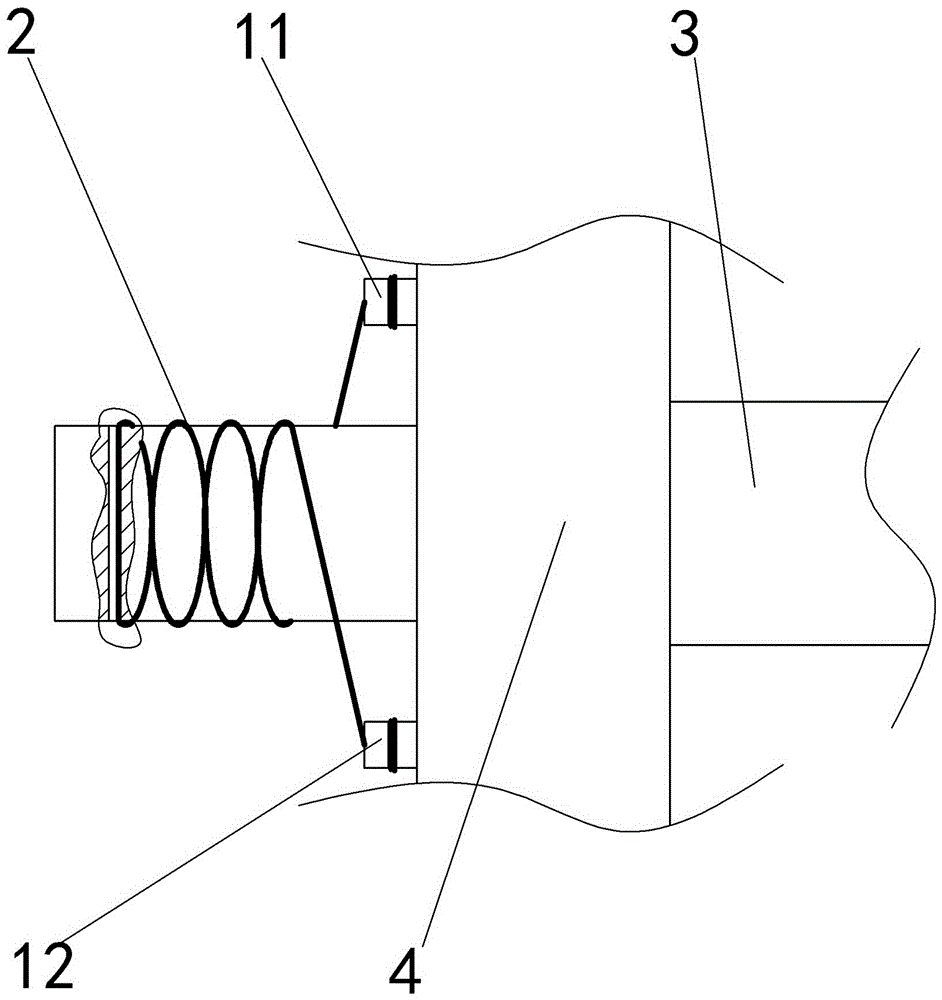

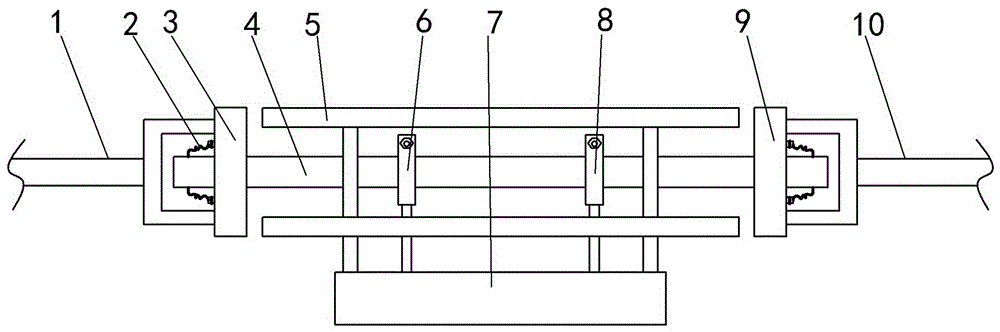

[0018] Embodiment: the axle class torsion test device in this scheme, as figure 2 As shown, it includes a twisted wire 2 made of carbon fiber, a fixed table 7, four strain gauges 5 providing a first driving device 1 and a second driving device 10 providing torque, the first driving device 1 and the second driving device 10 They are located on both sides of the fixed platform 7 respectively. A first support rod and a second support rod are respectively fixed at both ends of the fixed table 7 , a ring-shaped first clamp 6 is mounted on the top of the first support rod, and a ring-shaped second clamp 8 is mounted on the second support rod. Four strain gauges 5 are fixed on the fixed platform 7 and evenly distributed in the circumferential direction of the optical axis 4 . The first disc 3 is installed on the output end of the first driving device 1, and the center of the first disc 3 is integrally formed with a first through hole, and the side of the first disc 3 away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com