Discharging mechanism of high-molecular material and discharging device thereof

A polymer material and blanking technology, which is applied in the field of polymer material blanking mechanism and its blanking device, can solve the problems of blanking blockage and low blanking accuracy, and achieve the effect of substitute blanking accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

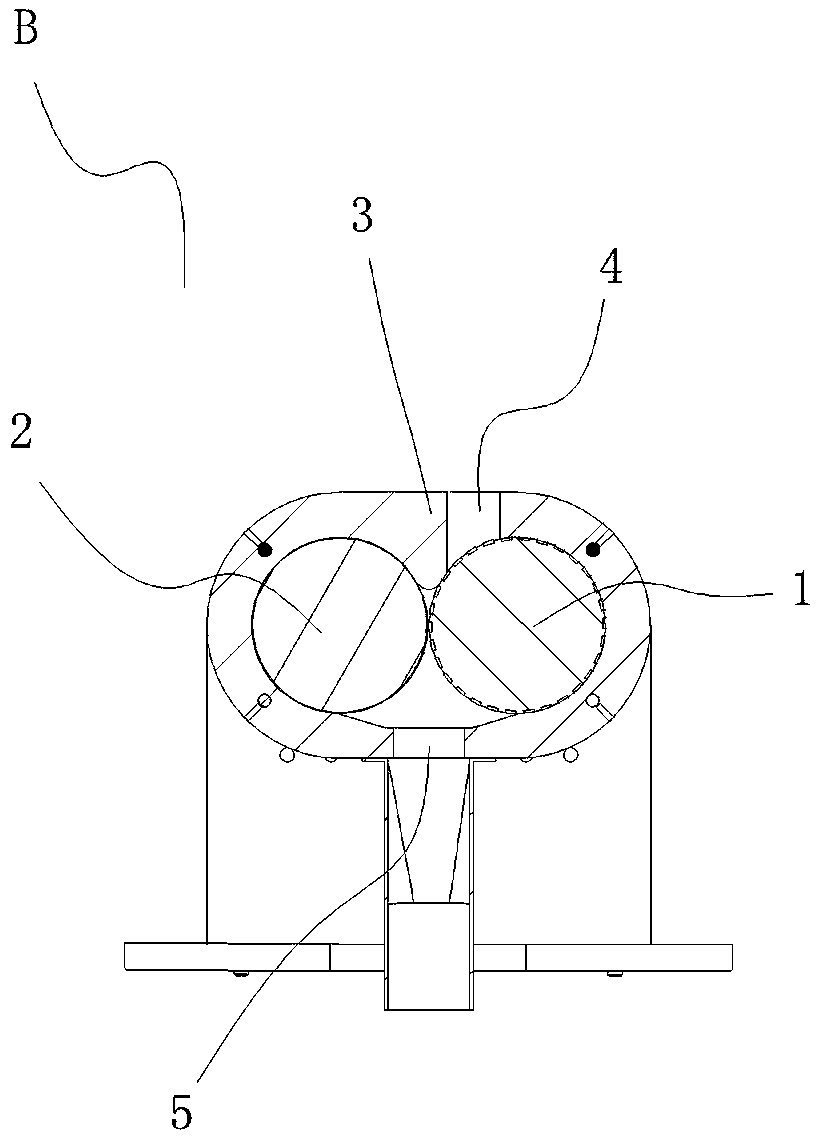

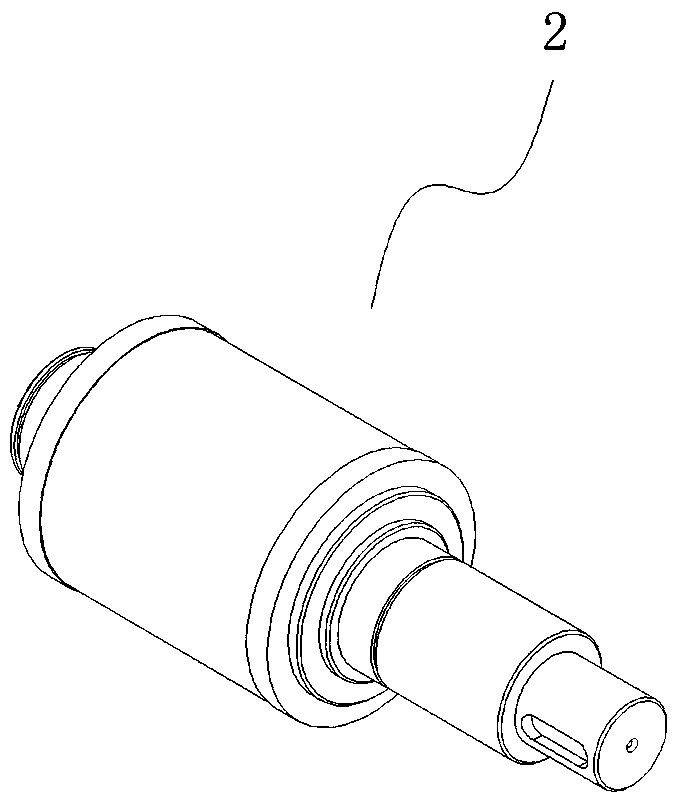

[0032] like figure 1 As shown, a technical scheme of a blanking mechanism B of a polymer material, which includes a blanking roller 1, an auxiliary blanking roller 2 and a blanking shell 3, and the blanking roller 1 and the secondary blanking roller 2 Mesh with each other; the blanking shell 3 is sheathed outside the blanking roller 1 and the auxiliary blanking roller 2 .

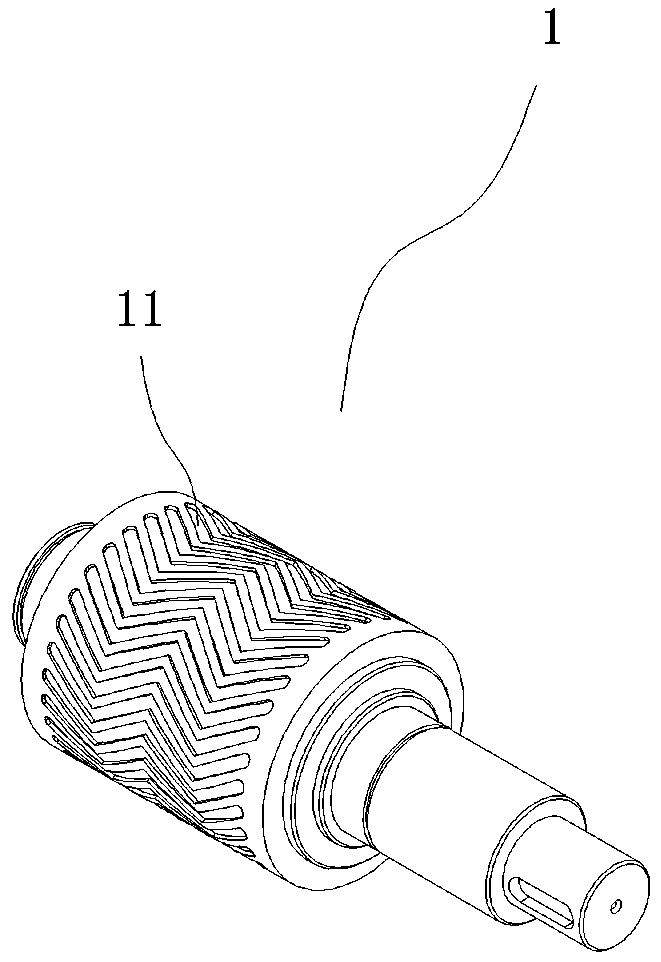

[0033] like Figure 1 to Figure 3 As shown, the blanking roller 1 and the auxiliary blanking roller 2 are equipped with a blanking groove, and the form of the blanking groove 11 of the blanking roller 1 is adapted to the weight of the polymer material to be blanked. The depth of the blanking chute of the auxiliary blanking roller 2 is adapted to the particle size of the polymer material to be blanked; there are Gap, and the size of the gap is adapted to the particle size of the polymer raw material to be unloaded.

[0034] like figure 1 and figure 2 As shown, the outer surface of the unloading roll 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com