Turbofan engine with mode adjusting capacity

An adjustment capability, turbofan technology, applied in the direction of machine/engine, gas turbine device, mechanical equipment, etc., can solve the problems of single working state, limited working range, small flight envelope, etc., to reduce fuel consumption and widen the flight envelope. line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

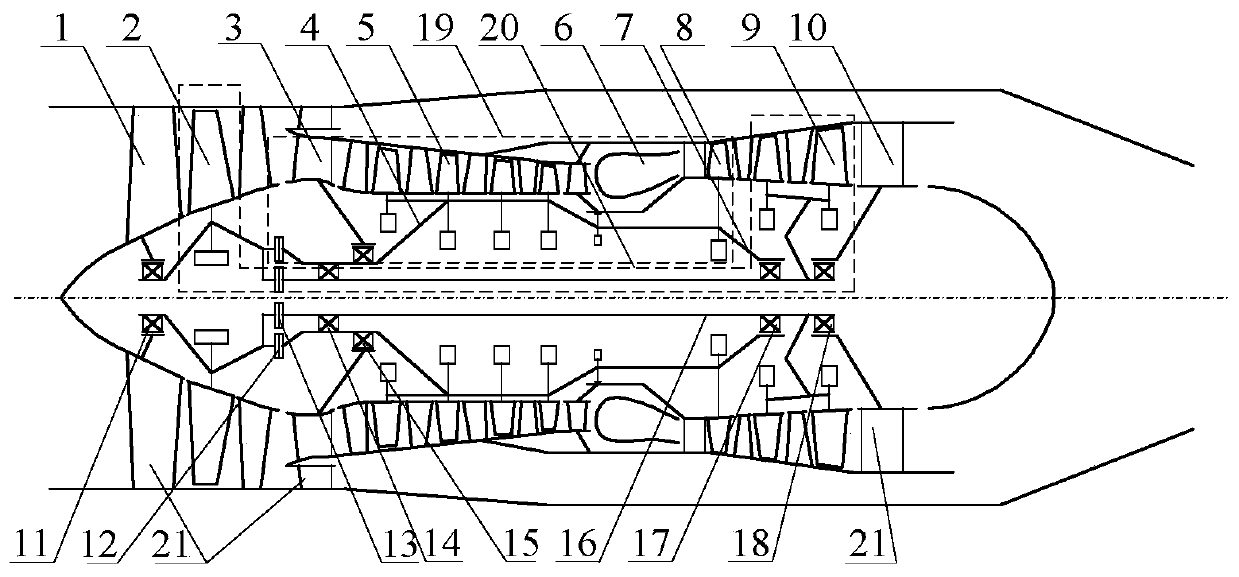

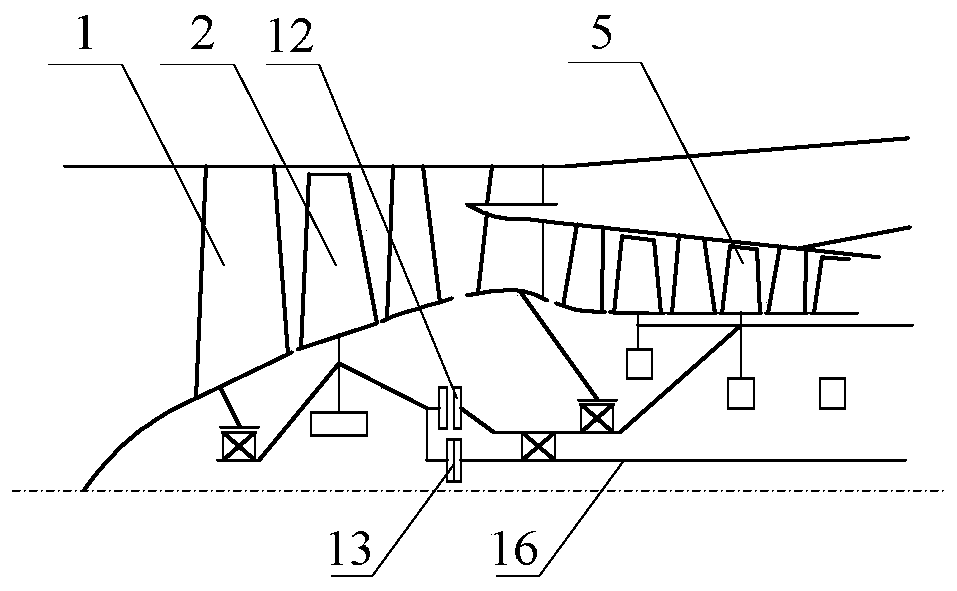

[0014] Implementation Mode 1: Combining the attached figure 1 with figure 2 , when the aircraft takes off with a full load or requires a large thrust, the first clutch 12 is disconnected, the second clutch 13 is connected, and the low-pressure turbine 9 transmits torque to the fan 2 through the low-pressure turbine shaft 16 to drive it to work. At this time, the engine is in a normal state. In the working mode, the high-pressure system 19 and the low-pressure system 20 work at the same time, and the engine generates thrust simultaneously from the external and internal airflows, and the thrust is maximum.

Embodiment approach 2

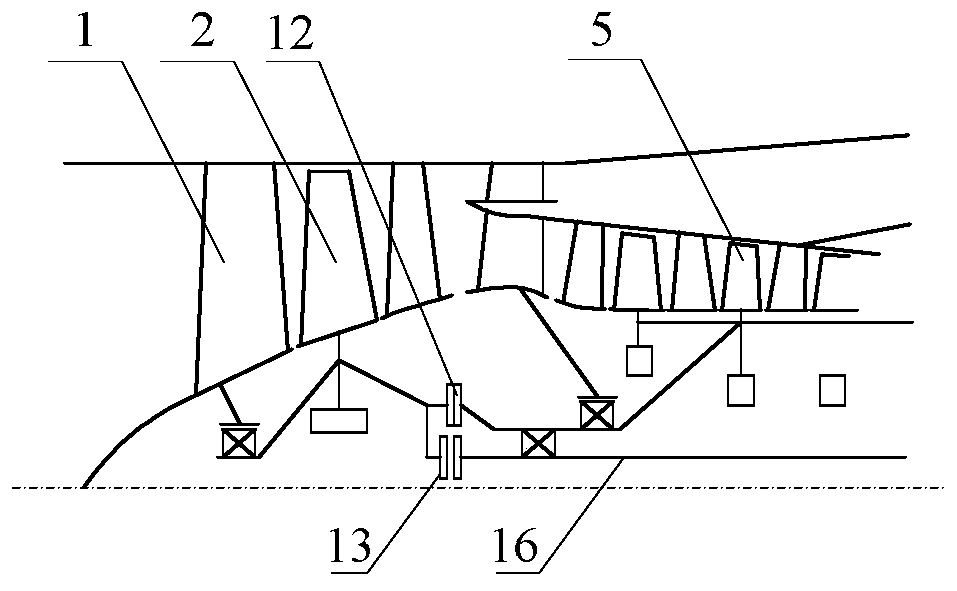

[0015] Implementation Mode 2: Combining the attached figure 1 with image 3 , when the aircraft requires the engine to provide a medium thrust level, the first clutch 12 is connected, and the second clutch 13 is disconnected. At this time, the high-voltage system 19 is switched to drive the fan 2. Since the high-voltage system 19 needs to output part of the power to the fan 2, so the high-pressure system 19 will rotate at a reduced speed, and the engine will generate thrust from the high-pressure system 19 and the fan 2.

Embodiment approach 3

[0016] Implementation Mode Three: Combining the Attached figure 1 with Figure 4 , when the aircraft is under light load or low-speed cruise, the engine only needs to provide thrust that meets the minimum requirements. At this time, both the first clutch 12 and the second clutch 13 are disconnected, the fan 2 stops rotating, and only the high-voltage system 19 works alone , the thrust of the engine comes from the internal high-temperature gas flow, and the thrust is the minimum at this time.

[0017] The aircraft engine of the present invention is designed with two clutches such as the first clutch 12 and the second clutch 13 altogether, and both clutches can realize connecting and driving with the fan 2, but the two clutches belong to the high pressure system 19 and the low pressure system 20 respectively. Two different rotor systems, so when the engine is working, it must be ensured that only one of the first clutch 12 and the second clutch 13 can be connected to the fan 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com