Anti-shake structure, anti-shake system and camera device

A technology of accommodating cavity and end pins, which is applied in the field of cameras, and can solve problems such as the complex internal structure of the anti-shake structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

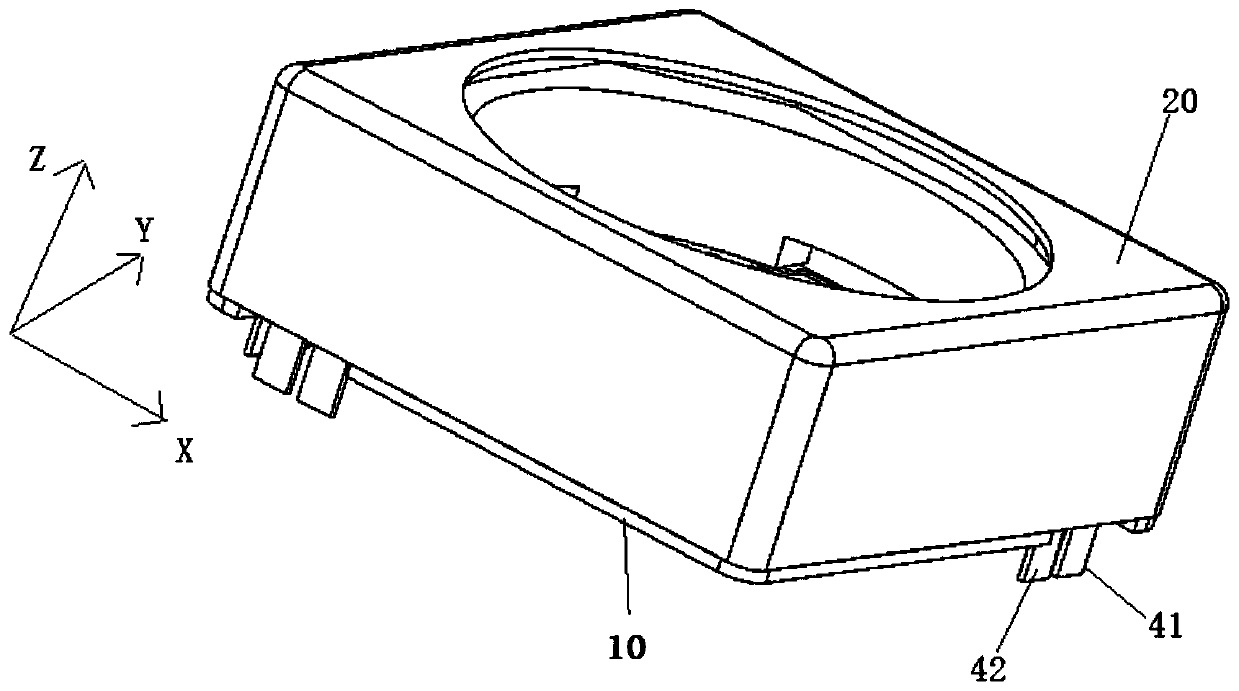

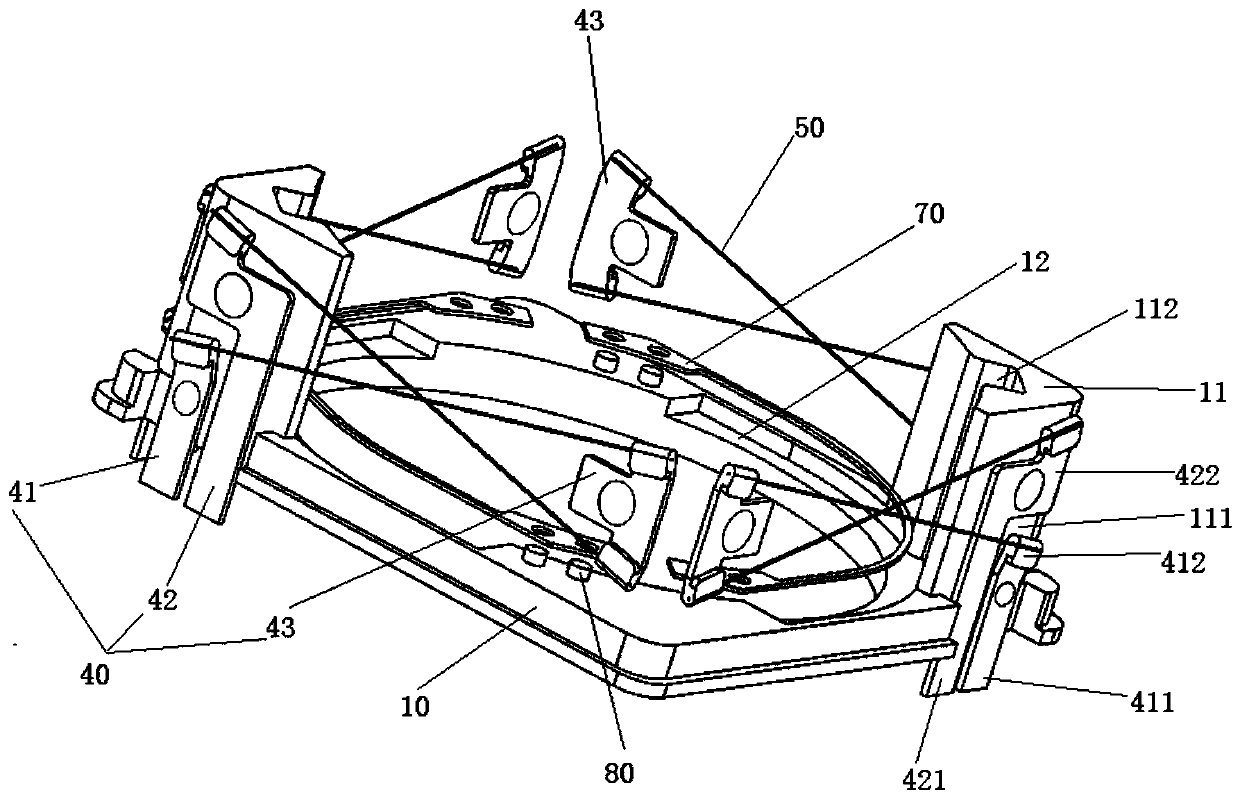

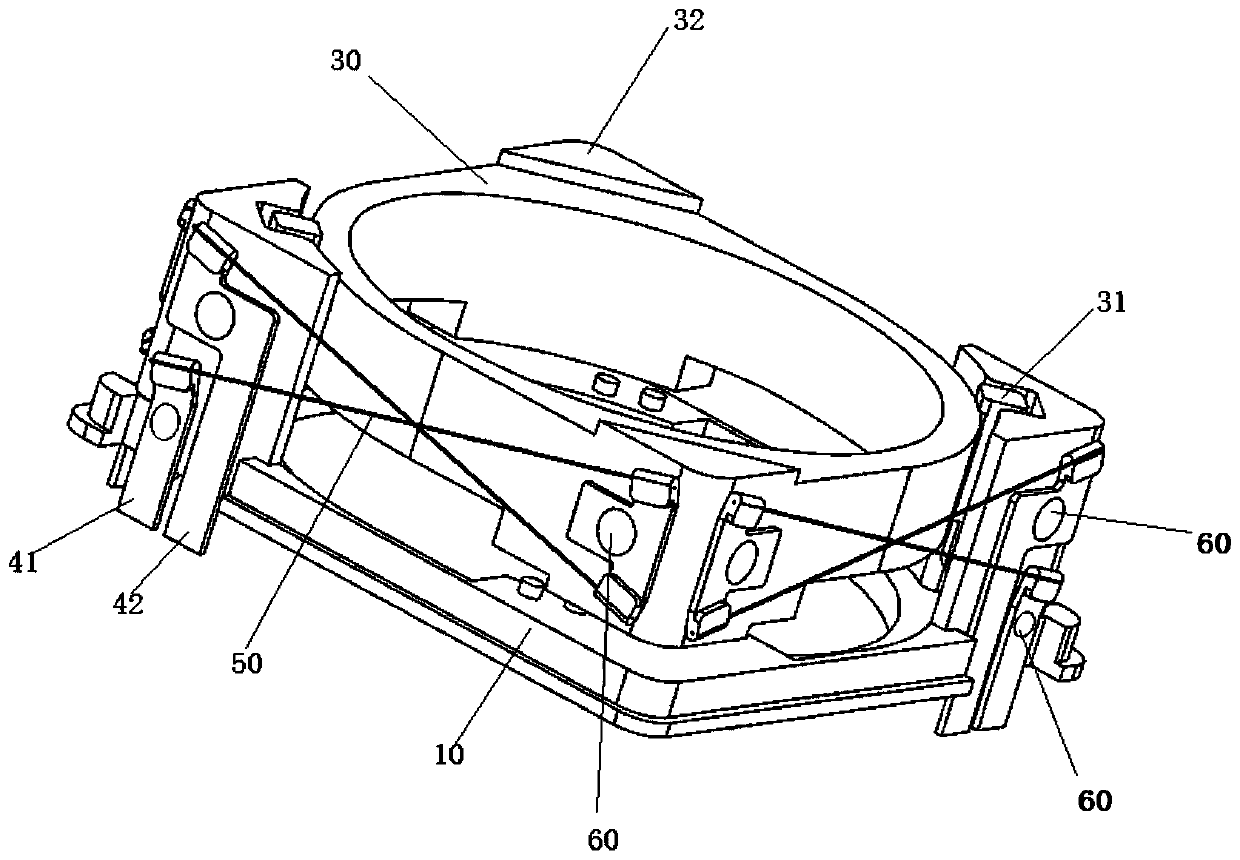

[0053] Such as Figure 1 to Figure 5 As shown, the anti-shake structure in this application includes a base 10 , a housing 20 , a lens support 30 , at least four sets of PIN pin structures 40 , a plurality of SMA wires 50 and a spring 70 . The housing 20 is covered on the outside of the base 10 and forms an accommodating cavity between the two; the lens support body 30 is disposed in the accommodating cavity; at least four groups of PIN pin structures 40 are located in the accommodating cavity, and each of the base 10 At least one set of PIN terminal pin structures 40 are correspondingly arranged on the sides, and each set of PIN terminal pin structures 40 includes a first PIN terminal pin 41, a second PIN terminal pin 42 and a pressing piece 43, and the first PIN terminal pin 41 and the second PIN terminal feet 42 are independently arranged on the base 10, and the pressing piece 43 is arranged on the lens support body 30; each group of PIN terminal foot structures 40 is corre...

Embodiment 2

[0092] The difference from Embodiment 1 is that the PIN pin structure 40 is integrally embedded and molded by means of INSERT MOLDING.

[0093] Optionally, at least a part of the pressing piece 43 is embedded in the lens support body 30 , and the connection end of the pressing piece 43 is located outside the lens support body 30 .

[0094] Optionally, at least a part of the first PIN terminal 41 is embedded in the base 10 , and the connection end of the first PIN terminal 41 is located outside the base 10 .

[0095] Optionally, at least a part of the second PIN terminal 42 is embedded in the base 10 , and the connection end of the second PIN terminal 42 is located outside the base 10 .

[0096] exist Figure 6 to Figure 8 In the specific embodiment shown, the pressing piece 43 is embedded in the lens support body 30 in an integral molding manner and the part connected to the SMA wire 50 is exposed, and the first PIN terminal pin 41 and the second PIN terminal pin 42 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com