Moxa cone manufacturing device

A technology for manufacturing devices and ai cones, which is applied in the direction of heating/cooling reflection point instruments, etc., can solve the problems of waste of manpower, short treatment time, low efficiency, etc., and achieve high production efficiency and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

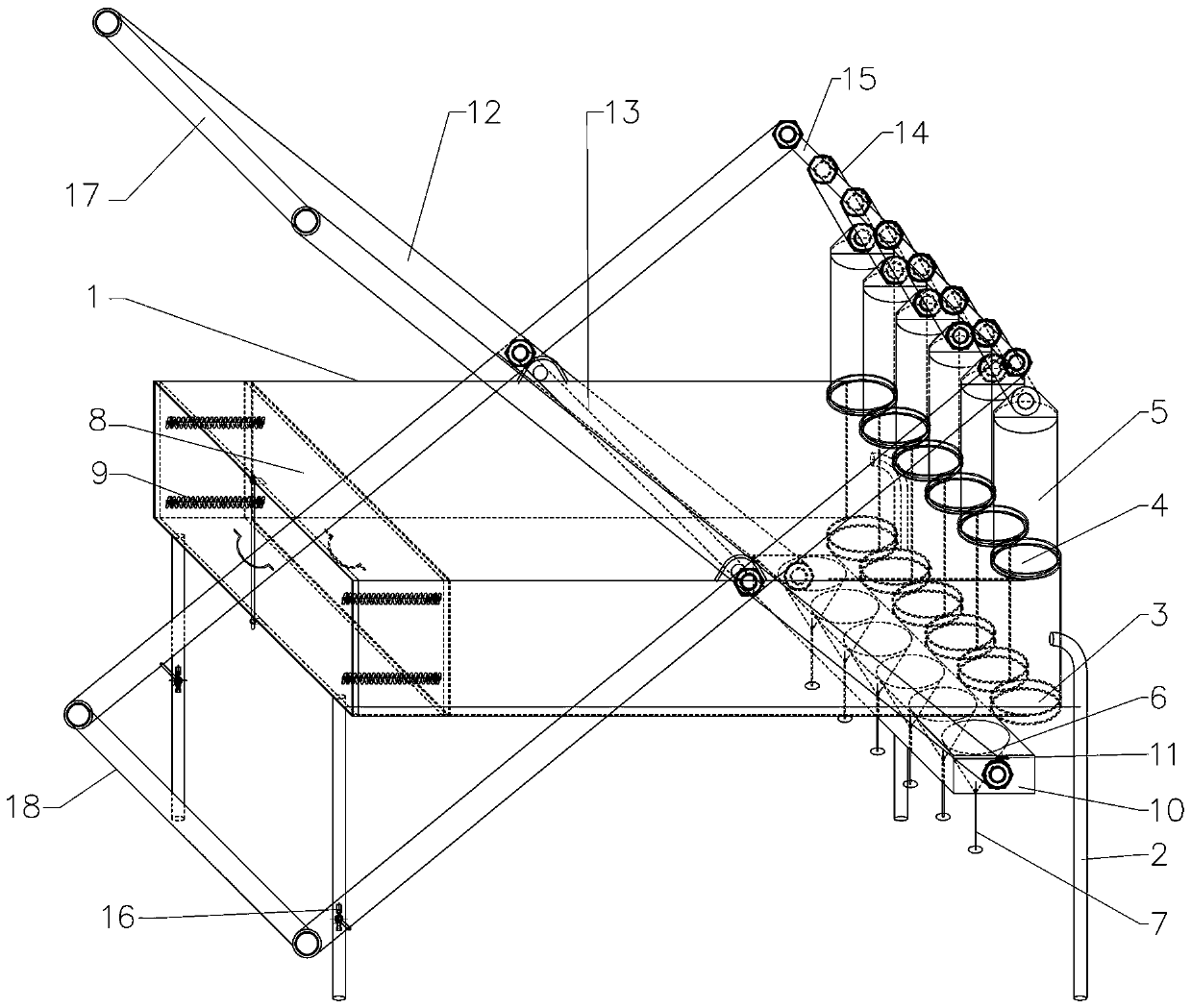

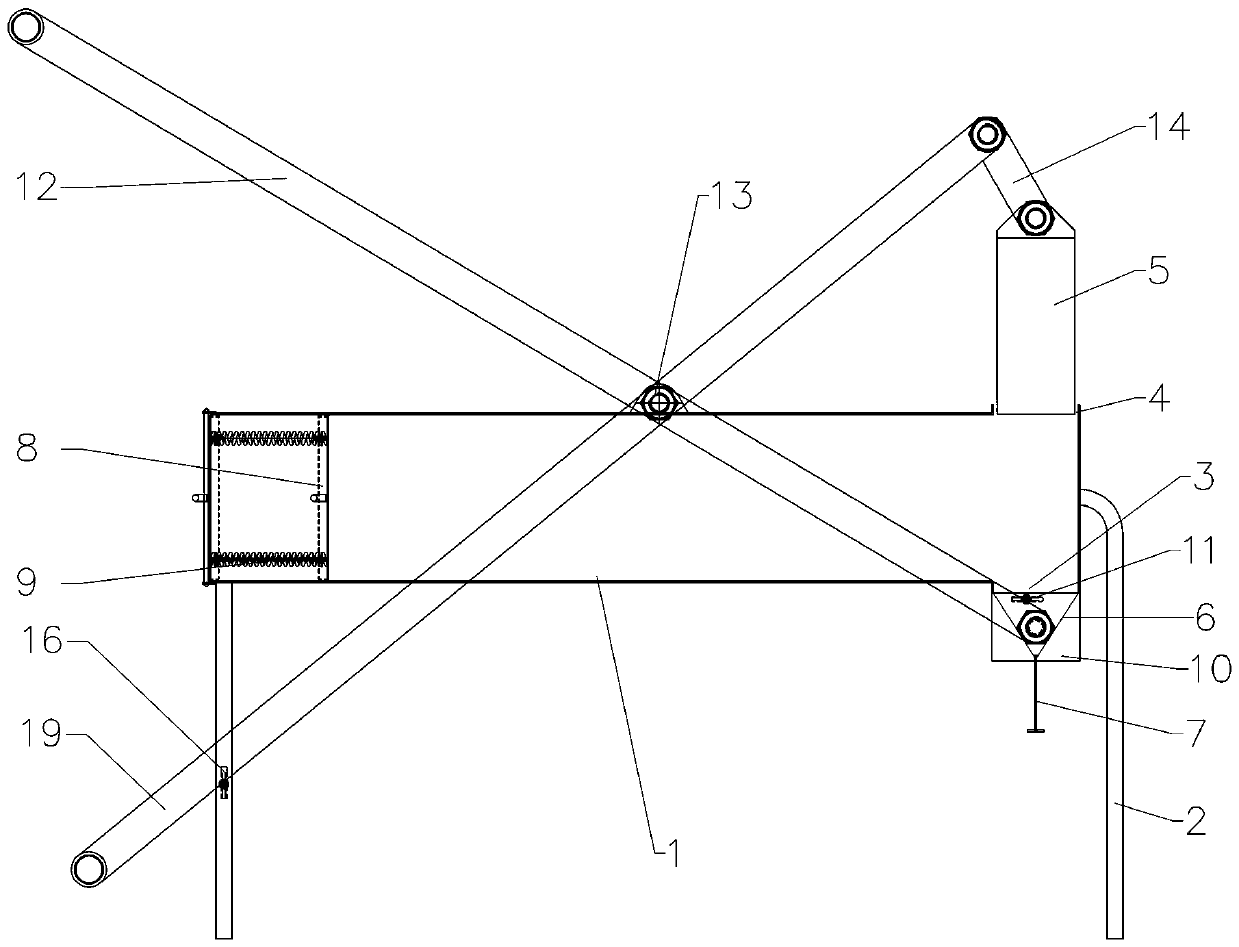

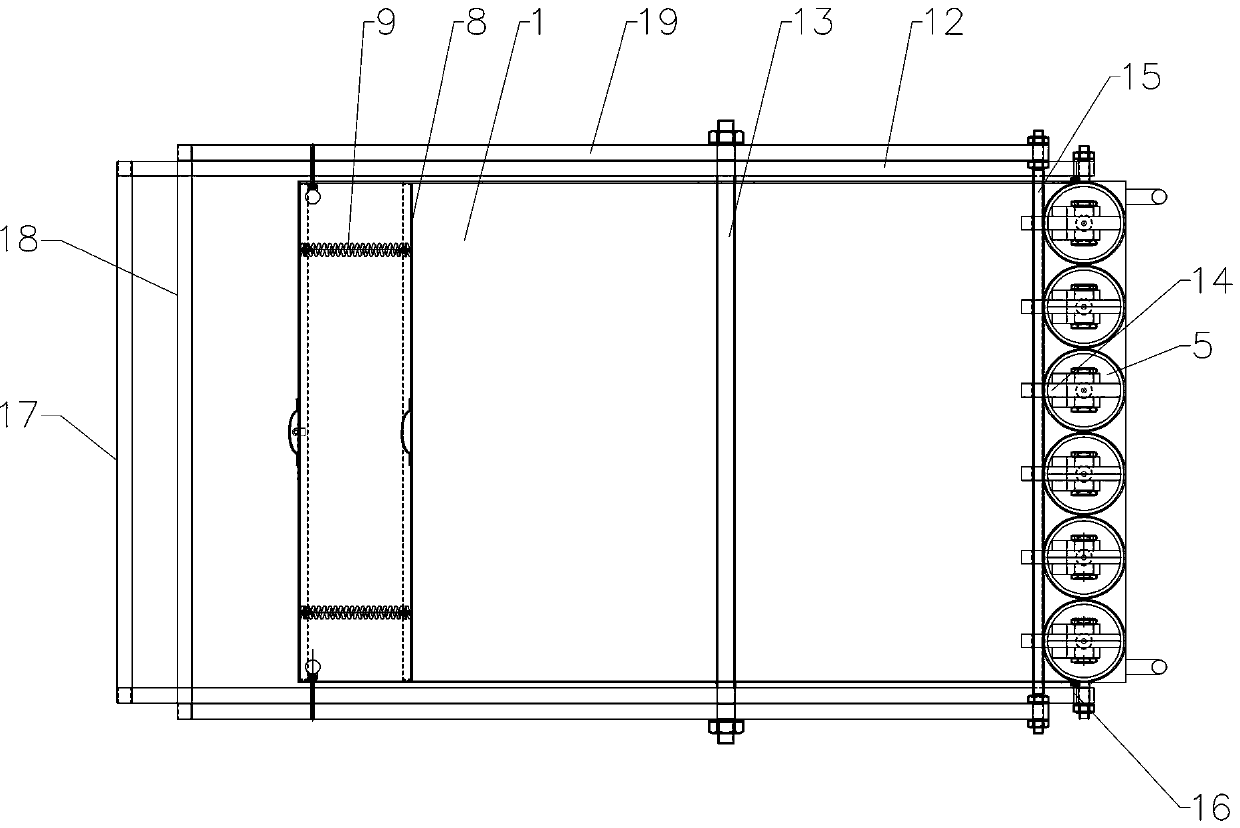

[0020] The specific structure of the present invention is further described below:

[0021] The structure of the present invention is as figure 1 The shown moxa cone production device includes a moxa leaf storage box 1, and the moxa leaf storage box is arranged on a frame 2. The inside of the mugwort storage box 1 is a regular rectangular groove, and on the opposite side of the discharge circular hole 3, there is a rectangular feeding push plate 8 covering the entire cross section of the groove, between the feed pushing plate 8 and the end surface of the groove A feed spring 9 is provided between them.

[0022] The other side of the mugwort storage box is provided with a plurality of discharging round holes 3 side by side, and the top of the mugwort storage box 1 above the discharging round holes 3 is provided with a pressing round hole 4, and the pressing round hole 4 and the discharging round hole 3 are concentric And the size is the same, the pressing hole 4 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com