Automobile anti-collision beam capable of reducing collision kinetic energy

A technology of anti-collision beams and automobiles, applied in the direction of bumpers, etc., can solve the problems of reduced safety, single protective measures, and inability to play a buffer, so as to reduce hard damage and increase the effect of safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

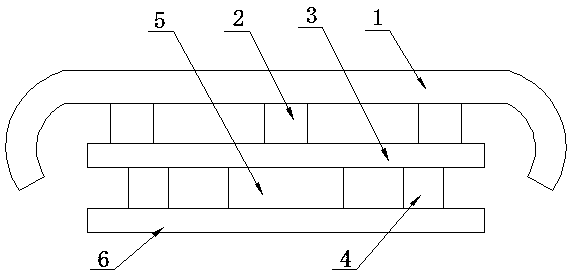

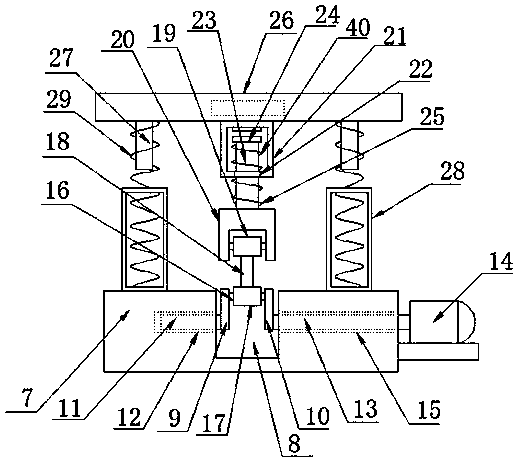

[0023] Such as Figure 1-2 As shown, an automobile anti-collision beam for reducing impact kinetic energy according to an embodiment of the present invention includes an anti-collision beam beam 1, and the bottom end of the anti-collision beam beam 1 is provided with a plurality of evenly distributed energy absorbing boxes 2, so The bottom end of the energy absorbing box 2 is provided with a load-bearing plate 3, the bottom end of the load-bearing plate 3 is provided with buffer components 4 symmetrically on both sides, and the middle of the bottom end of the load-bearing plate 3 is provided with a damping mechanism 5. 4 and the bottom end of the damping mechanism 5 are connected to the mounting plate 6. The damping mechanism 5 includes a base plate 7 at the top of the mounting plate 6, and a slot 8 is provided in the middle of the top of the base plate 7. The slot 8 is provided with a rocker 9 and a rocker 2 10 respectively. One end of the rocker 9 away from the rocker 2 10 is...

Embodiment 2

[0026] Such as figure 2 As shown, the inner wall of the cavity of the sleeve 21 away from the through hole 22 is provided with an elastic block adapted to the limiting plate 24.

[0027] Such as figure 2 As shown, the bottom end of the rotating electric machine 14 is provided with a base, and one side of the base is connected to the substrate 7.

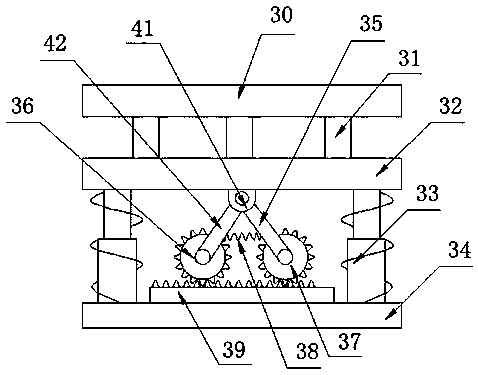

[0028] Such as image 3 As shown, the buffer assembly 4 includes a second movable plate 30 connected to the bottom end of the load-bearing plate 3, and the bottom end of the second movable plate 30 is provided with a number of uniformly distributed rubber blocks 31. The bottom end is connected to the third movable plate 32, the bottom end of the third movable plate 32 is provided with telescopic components 33 symmetrically on both sides, and the bottom end of the telescopic component 33 is connected to the second base plate 34 located at the top of the mounting plate 6.

[0029] Such as image 3 As shown, the telescopic assembly 33 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com