Beam tube type light optical cable

A bundle-type, light-weight technology, applied in the field of optical cable manufacturing, can solve the problems of reducing PE sheath, insulation outer wall cracks, etc., to improve work performance, improve bending resistance and damage resistance, and ensure stable work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

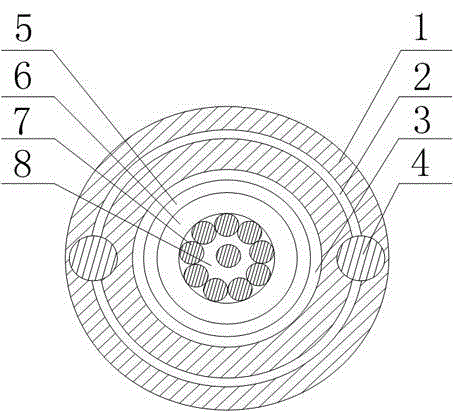

[0019] Such as figure 1 As shown, this embodiment includes a PE sheath 1 and a central sleeve 6 arranged in the middle of the PE sheath 1, the central sleeve 6 is filled with fiber paste 8, and a plurality of optical fibers 7 are fixed in the central sleeve 6 In the PE sheath 1, two copper wires 4 are symmetrically arranged along its axis, and also include a plurality of annular reinforcing ribs 2 arranged in the PE sheath 1, and the plurality of reinforcing ribs 2 are arranged along the PE sheath. The sleeve 1 is sleeved on two copper wires 4 at equal radial intervals. In view of the problems in the prior art that the ribbon optical cable is prone to breakage or its insulating outer wall is prone to cracks, the present invention firstly arranges two copper wires 4 symmetrically along its axis in the PE sheath 1 and multiple equidistantly spaced ones. The annular reinforcing rib 2, and a plurality of annular reinforcing ribs 2 are sleeved on two copper wires 4 along the radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com