Handling robot and working method thereof

A technology for handling robots and working methods, applied in the field of handling robots, can solve the problems of small handling capacity of handling robots, and achieve the effect of improving handling efficiency and increasing handling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

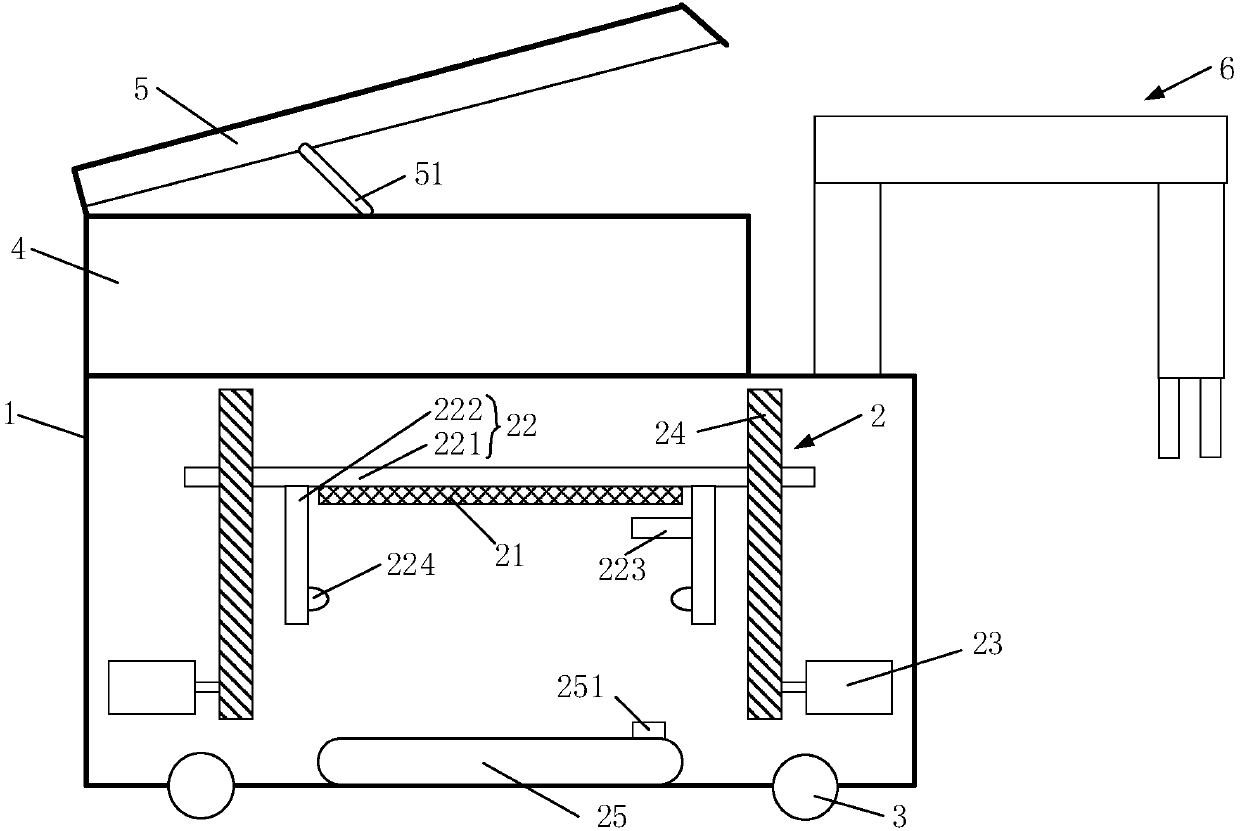

[0045] like Figure 1 to Figure 4 As shown, the present embodiment 1 provides a handling robot, including:

[0046] The main body 1, the main body is provided with a warehouse 4, and the warehouse 4 is provided with an electric cover 5;

[0047] The front end of the warehouse is provided with a six-degree-of-freedom manipulator 6;

[0048] When transporting materials, the controller in the body is suitable for opening the electric cover 5 and controlling the six-degree-of-freedom manipulator 6 to drop the grabbed materials into the warehouse 4 .

[0049] The electric cover can be realized by an electric strut, and the electric strut is controlled by a controller.

[0050] The handling robot and its working method put materials into the warehouse through the six-degree-of-freedom manipulator first, and then transport them to the destination. The handling capacity of the material is increased through the warehouse, and the handling efficiency is improved.

[0051] The transfe...

Embodiment 2

[0066] On the basis of Embodiment 1, Embodiment 2 provides a working method for a handling robot, including:

[0067] The main body and the main body are provided with a warehouse, and the warehouse is provided with an electric cover;

[0068] The front end of the warehouse is provided with a six-degree-of-freedom manipulator;

[0069] When transporting materials, the controller in the body is suitable for opening the electric cover to control the six-degree-of-freedom manipulator to drop the grabbed materials into the warehouse.

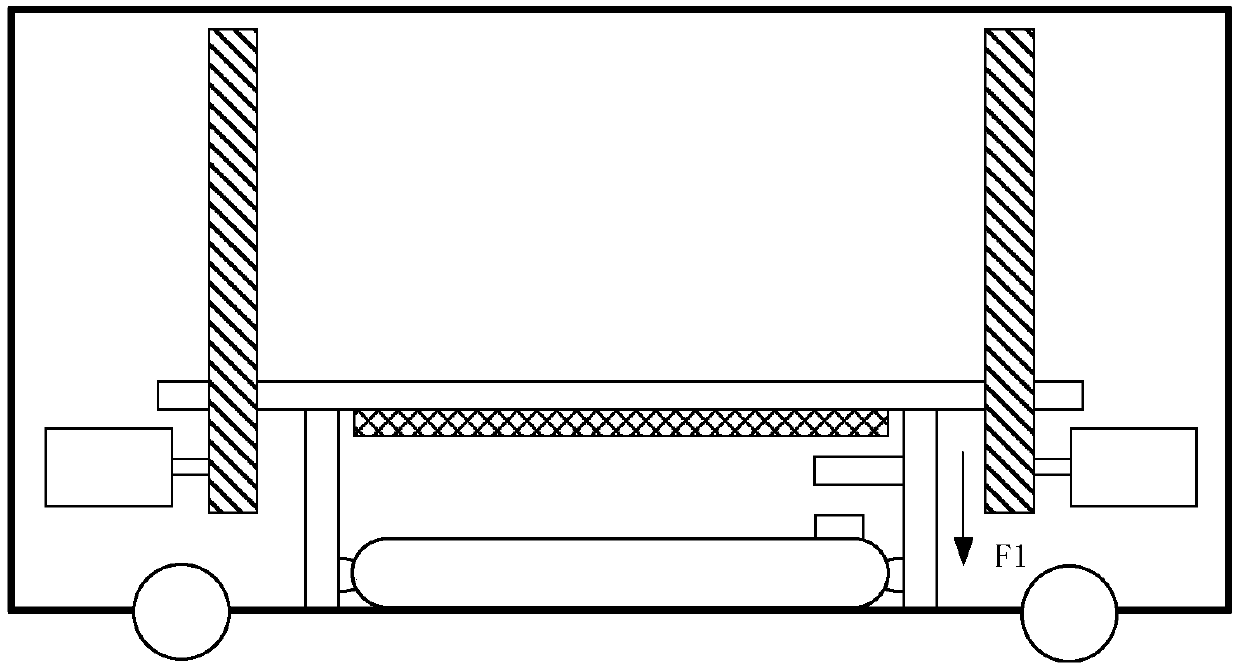

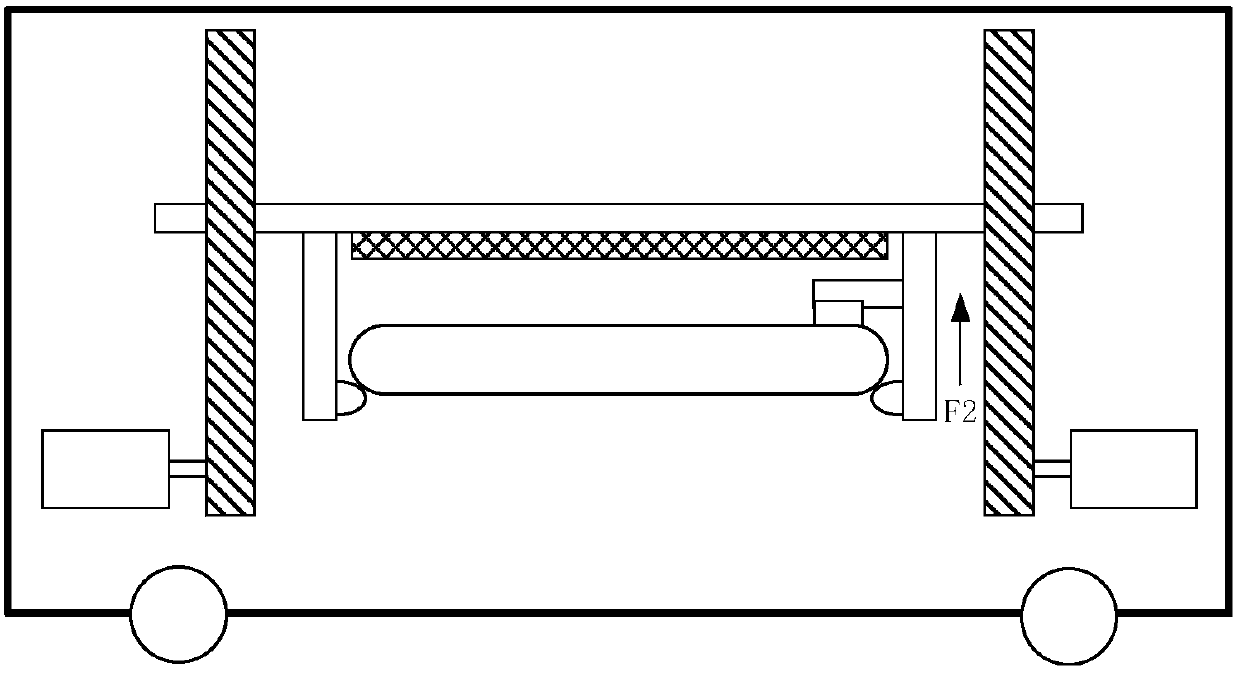

[0070] The handling robot also includes a wireless module, a magnetic attraction mechanism 2 located at the bottom of the body 1 controlled by a controller, a wheel assembly 3 located at the bottom of the body 1, and a DC motor driven by the controller; the DC motor is suitable for driving the wheels Component 3 rotates; the controller is adapted to receive wireless control instructions through the wireless module, that is, when the handling robot ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap