Rubber extruder and screw for same

A rubber extruder and screw technology, applied in mixers, mixer accessories, mixers with rotary stirring devices, etc., can solve the problems of gasification of volatile components, poor performance, damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

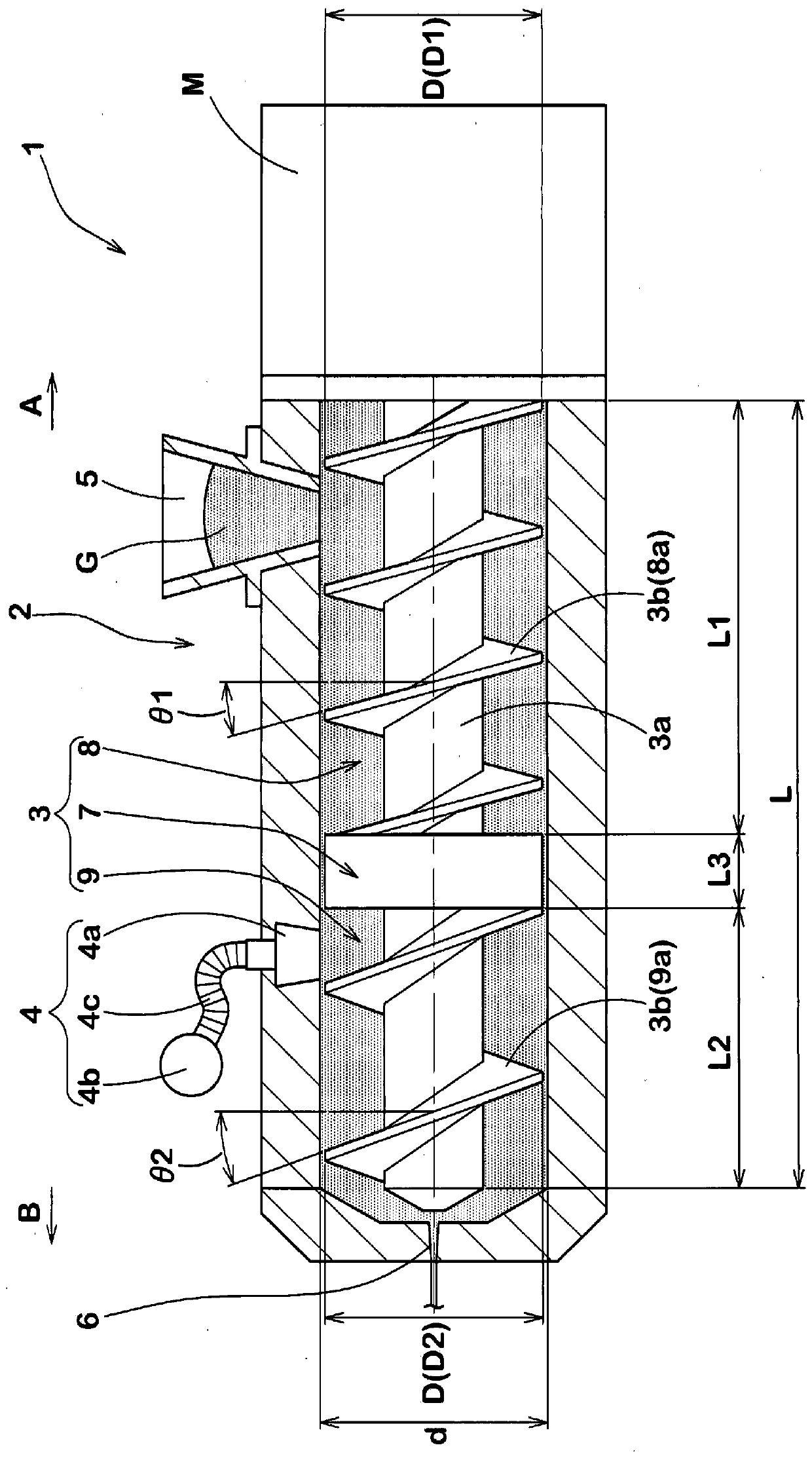

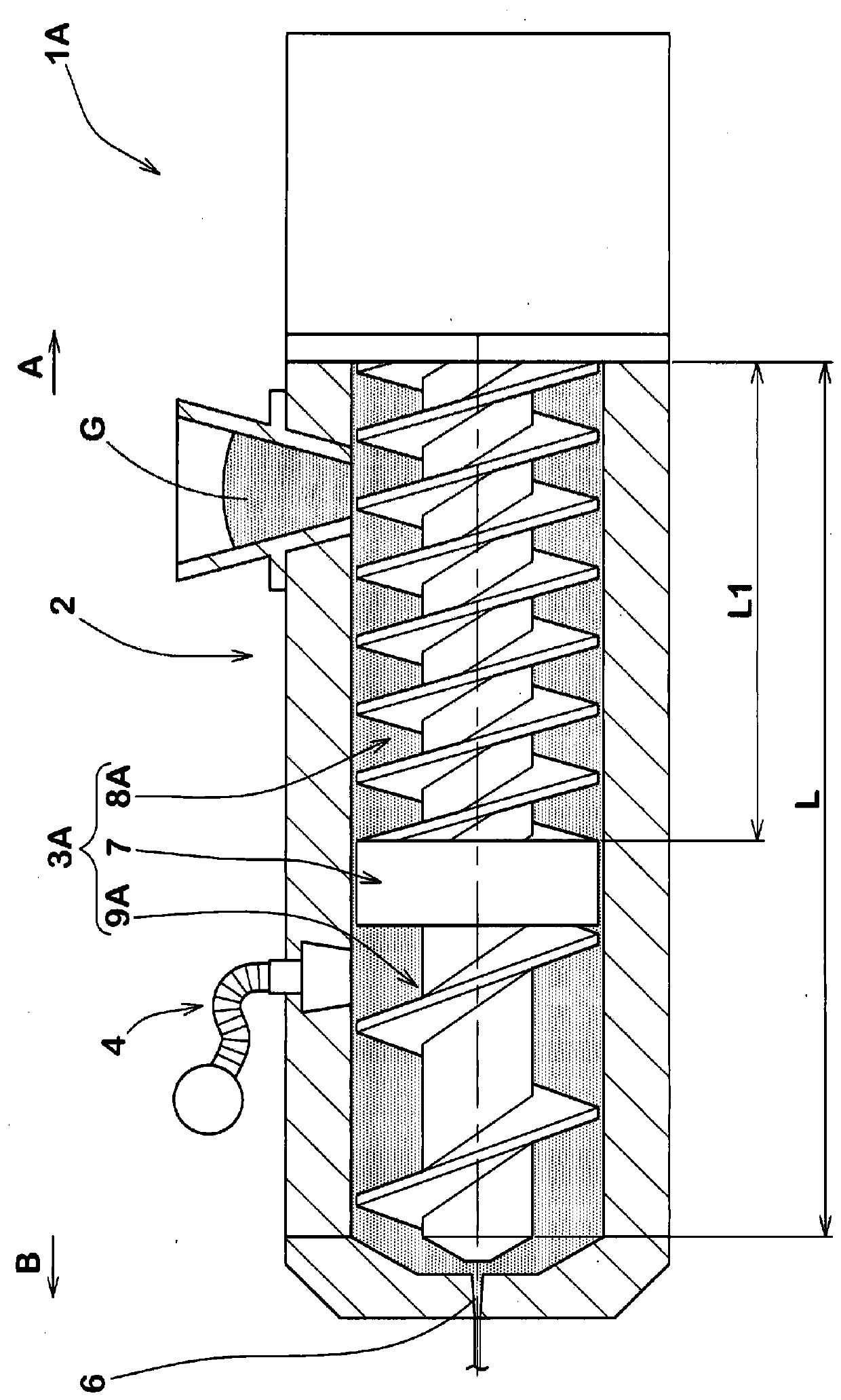

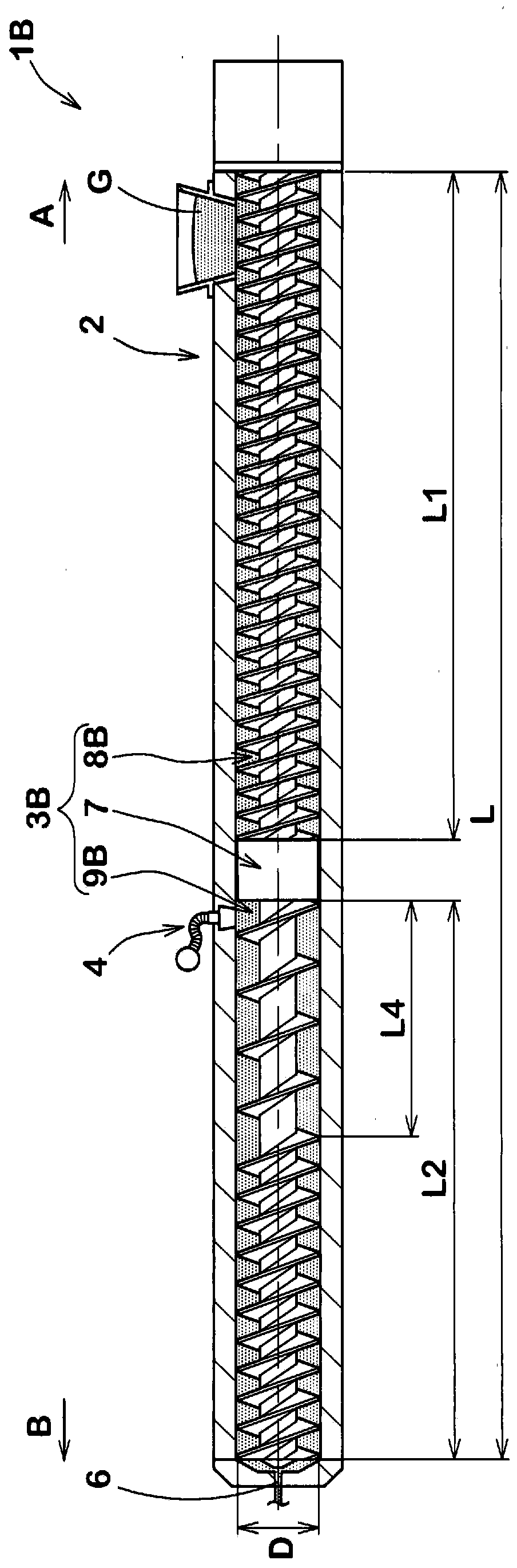

[0031] Hereinafter, one embodiment of the present invention will be described based on the drawings.

[0032] figure 1 It is a sectional view showing the rubber extruder 1 of this embodiment. Such as figure 1 As shown, the rubber extruder 1 of the present embodiment extrudes the unvulcanized rubber G from the upstream side A toward the downstream side B while stirring the unvulcanized rubber G. Preferably, the rubber extruder 1 includes: a substantially cylindrical body 2 ; a screw 3 disposed in the body 2 ; and an exhaust hole 4 for sucking air in the body 2 .

[0033] The cylinder body 2 has, for example, a substantially constant inner diameter d from the upstream side A toward the downstream side B in the extrusion direction of the unvulcanized rubber G. It is preferable that the cylindrical body 2 has an inlet 5 for injecting the unvulcanized rubber G in the peripheral portion on the upstream side A. As shown in FIG. In addition, it is preferable that the cylindrical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com