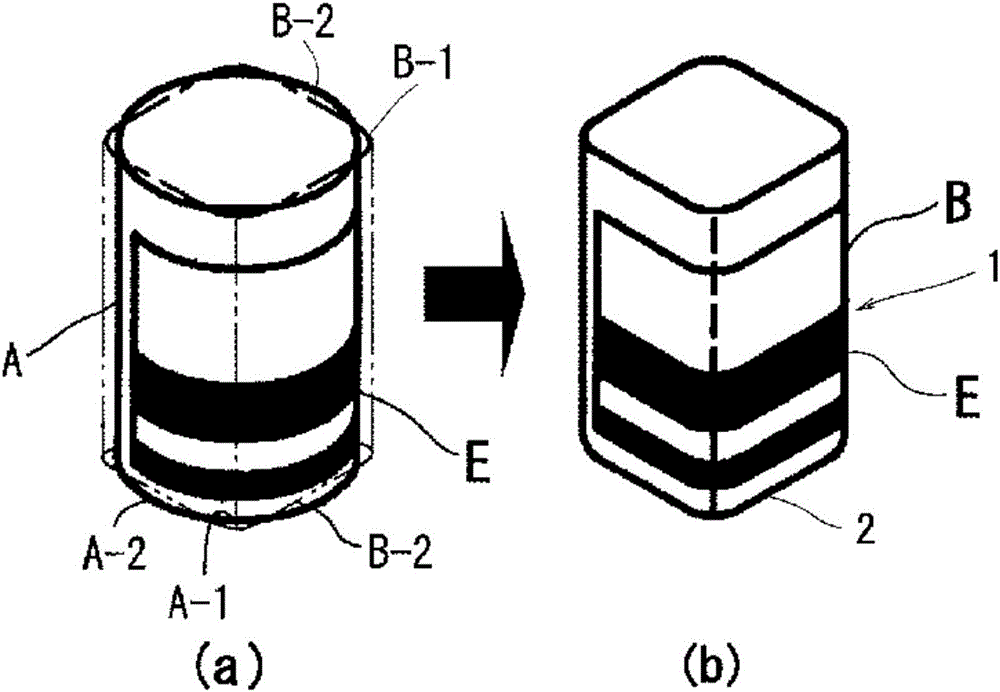

Polygonal container and method for forming same

A molding method, polygonal technology, applied in cans/barrels/barrels, other household utensils, transportation and packaging, etc., can solve the problems of polygonal cans with bottoms that cannot be formed, maintain quality and color rendering, prevent film peeling, The effect of improving portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

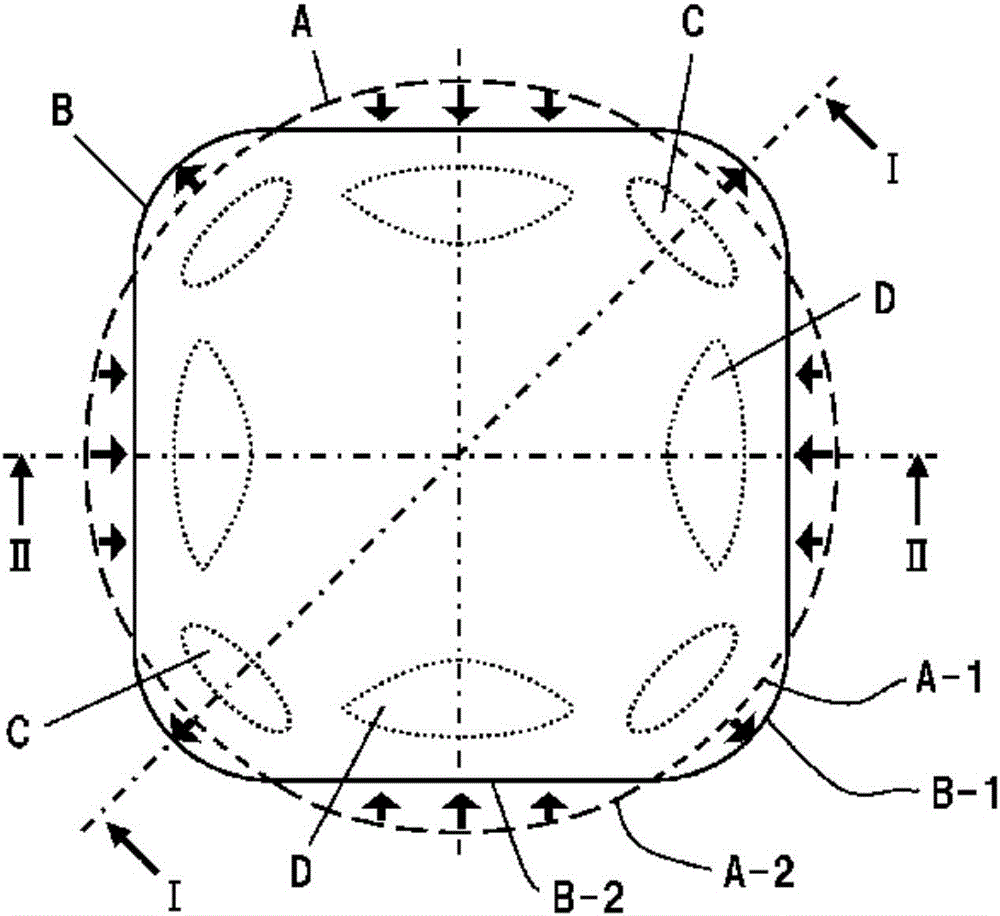

[0105] Figure 8 ~ Figure 10 An example of a polygonal can molding apparatus for implementing the polygonal can molding method of the present invention is shown.

[0106] In the figure, the part to the right from the center line shows the cross section of the corner forming part, and the part to the left shows the cross section of the straight part forming part. The polygonal tank molding device according to this embodiment is composed of an upper mold assembly 10 and a lower mold assembly 30, and both are arranged so as to be able to come into relative contact with or separate from each other along the coaxial direction. The upper die base 11 of the upper die assembly 10 is provided with a drooping inner die assembly 12 and a drooping extruding tool operating rod 25 , and an abutment head 26 is provided at the lower end of the extruding tool operating rod 25 .

[0107] The inner assembly 12 is composed of a rotating shaft 13 for forming the straight part and the bottom of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com