Vertical drive arc-shaped gate bar valve device of chute

A valve device and arc-shaped technology, which is applied in the field of vertically driven arc-shaped grid rod valve devices, can solve the problems of manual operation of a single rod valve, failure to close, timely material cut-off and flow control, etc., to save human resources Low cost, small occupation of horizontal space, good for production arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

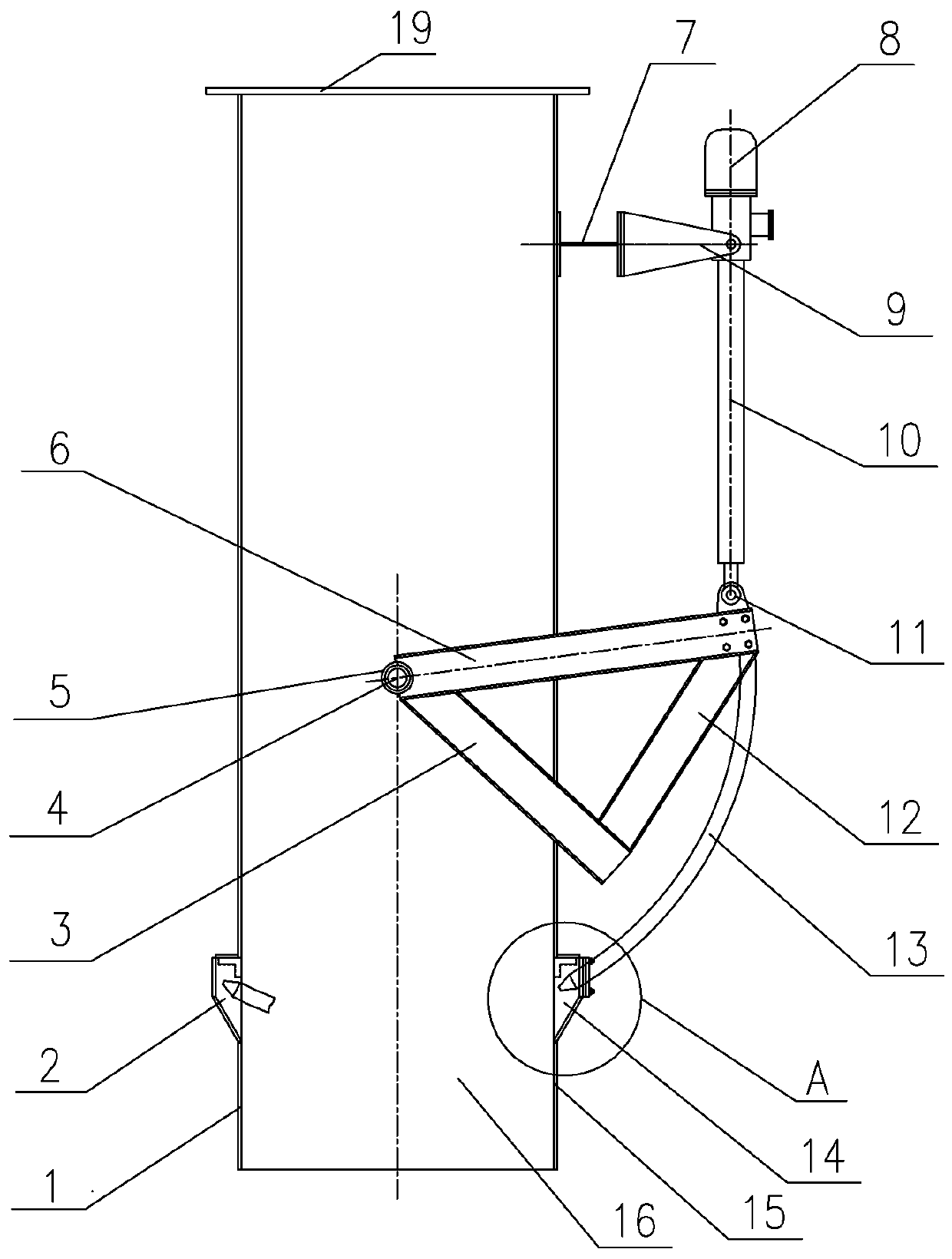

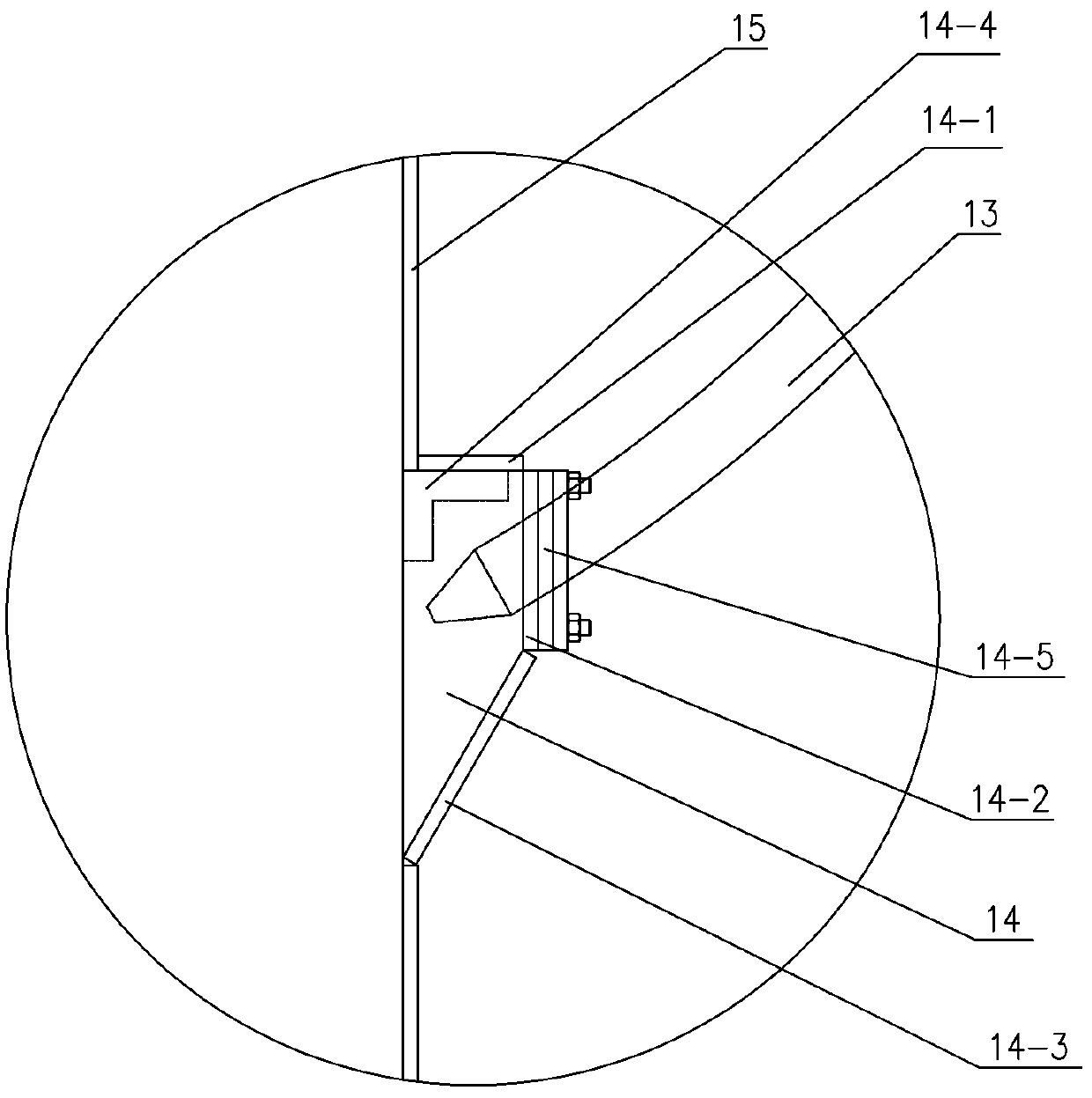

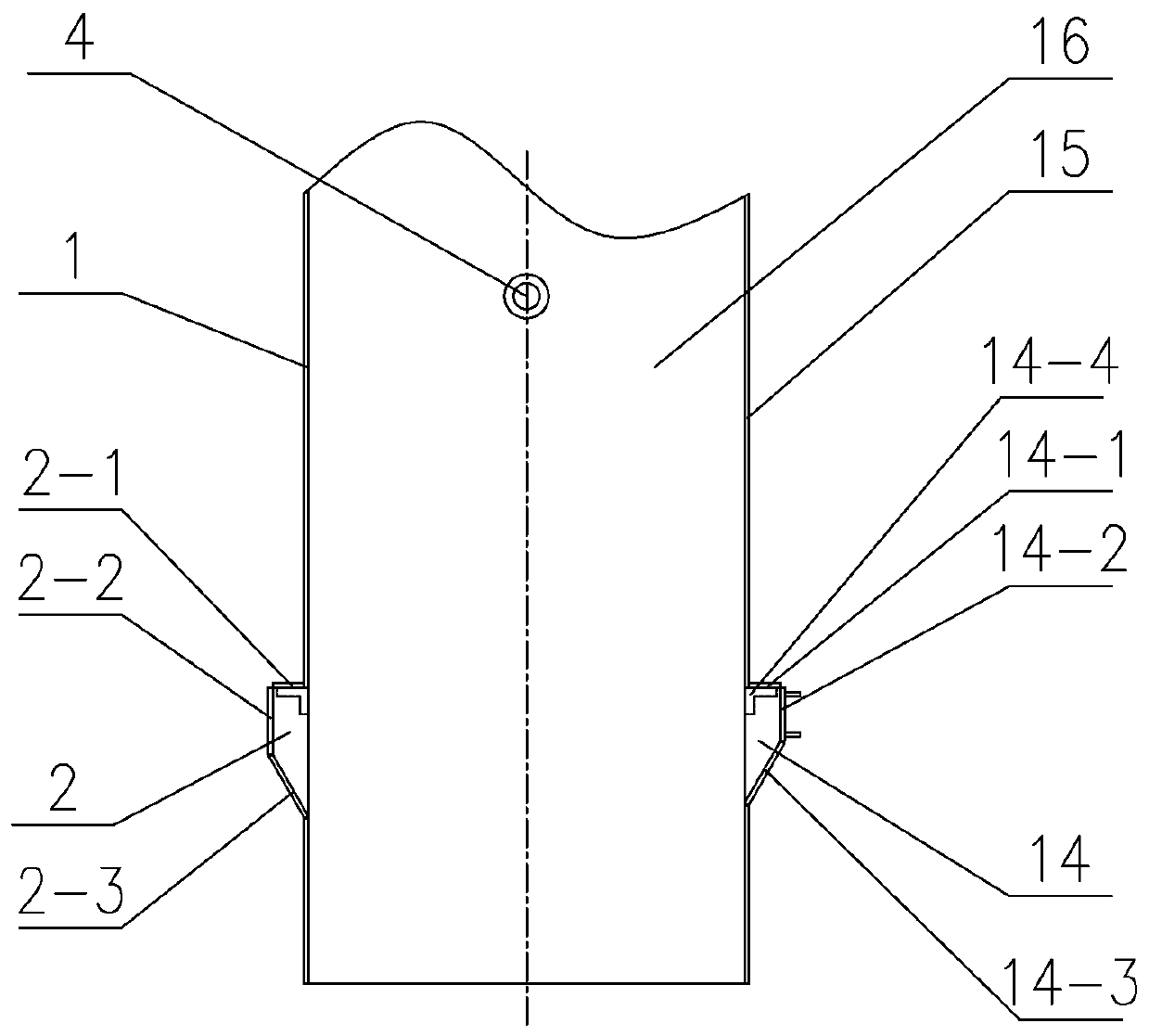

[0023] Such as Figure 1-Figure 8 As shown, a vertically driven arc-shaped grid rod valve device for a chute of the present invention includes a chute composed of a top flange 19, a front side plate 16, a rear side plate, a right side plate 15 and a left side plate 1. The top of the chute is fixed to the bottom of the ore bin by its top flange 19 bolts. It is characterized in that: an arc-shaped grid rod valve device is arranged on the lower part of the right side plate 15 of the chute, and the arc-shaped grid rod valve device includes an arc-shaped grid rod valve device. Grid rod valve and hydraulic system, the arc-shaped grid rod valve includes a set of arc-shaped claw drill rods 13, a beam 17 and two triangular swing arms; The outer sides are respectively welded with trunnions 4, and the trunnions 4 are symmetrically located on the center vertical line of the front side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com