Washing machine

A technology of washing machines and washing tubs, which is applied to other washing machines, washing machines with containers, washing devices, etc., and can solve the problems of wasting water, the chamber cannot be cleaned and polluted, and the water cannot be completely discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

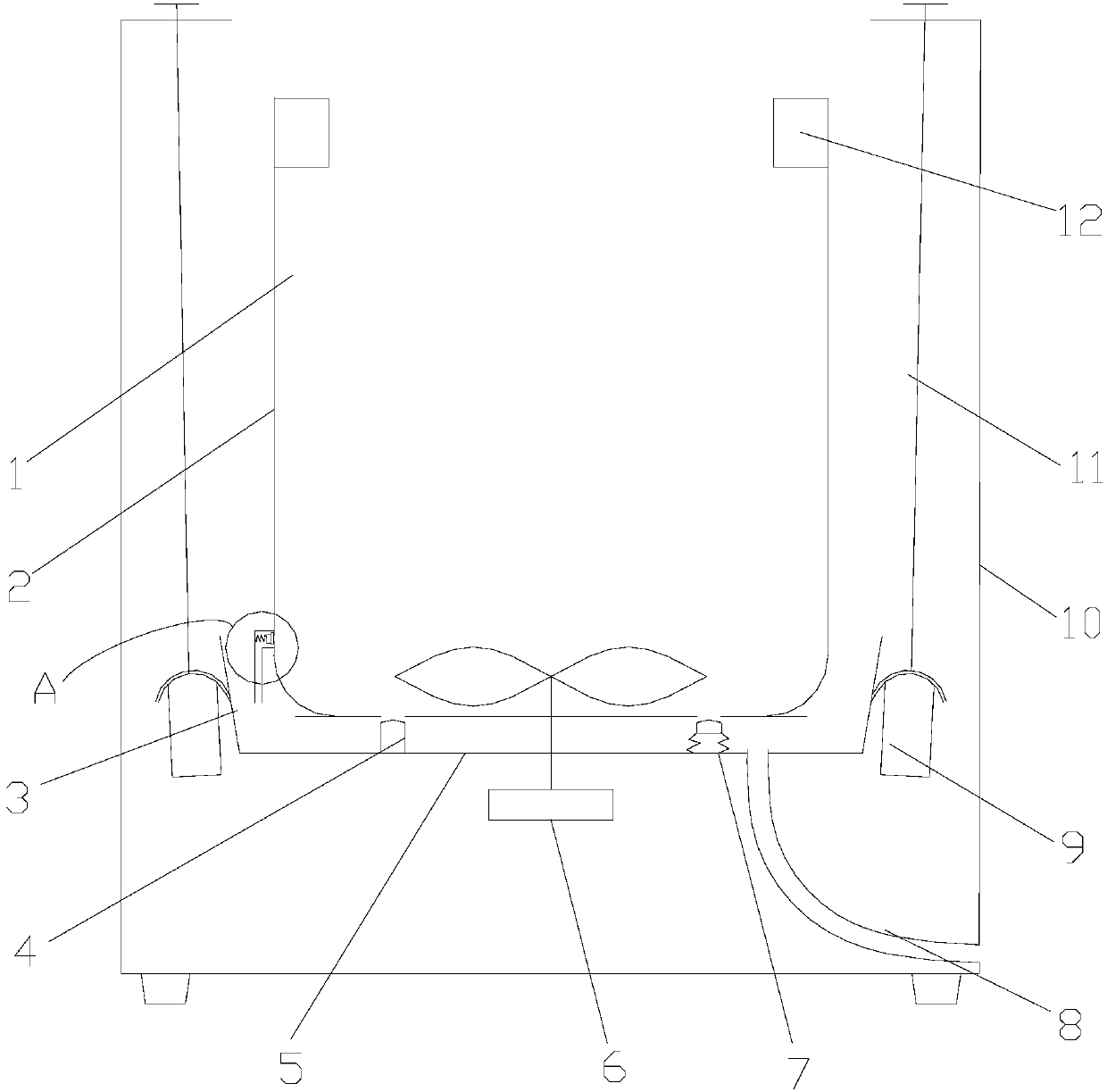

[0032] Such as Figure 1 to Figure 2 As shown, a washing machine is introduced in this embodiment, which includes a casing 10, a washing bucket 2 arranged in the casing 10, and a motor 6 for driving the washing bucket 2 to rotate. The water channel 1 leading to the upper part and the balance ring 12 for maintaining the dynamic balance of the washing machine. In the embodiment of the present invention, the washing bucket 2 is a non-porous inner bucket, and the inner bucket is a closed container after the cover of the washing machine is closed. It integrates the dual functions of holding washing water and being electrically driven to rotate, and washing clothes with washing water, so that The washing machine does not need to be equipped with an outer tub, and only needs to utilize the washing tub 2 to achieve the effect of washing clothes at the same time.

[0033] In this embodiment, the washing machine also includes a bottom mounting plate 5 and a suspension rod 11 of the sho...

Embodiment 2

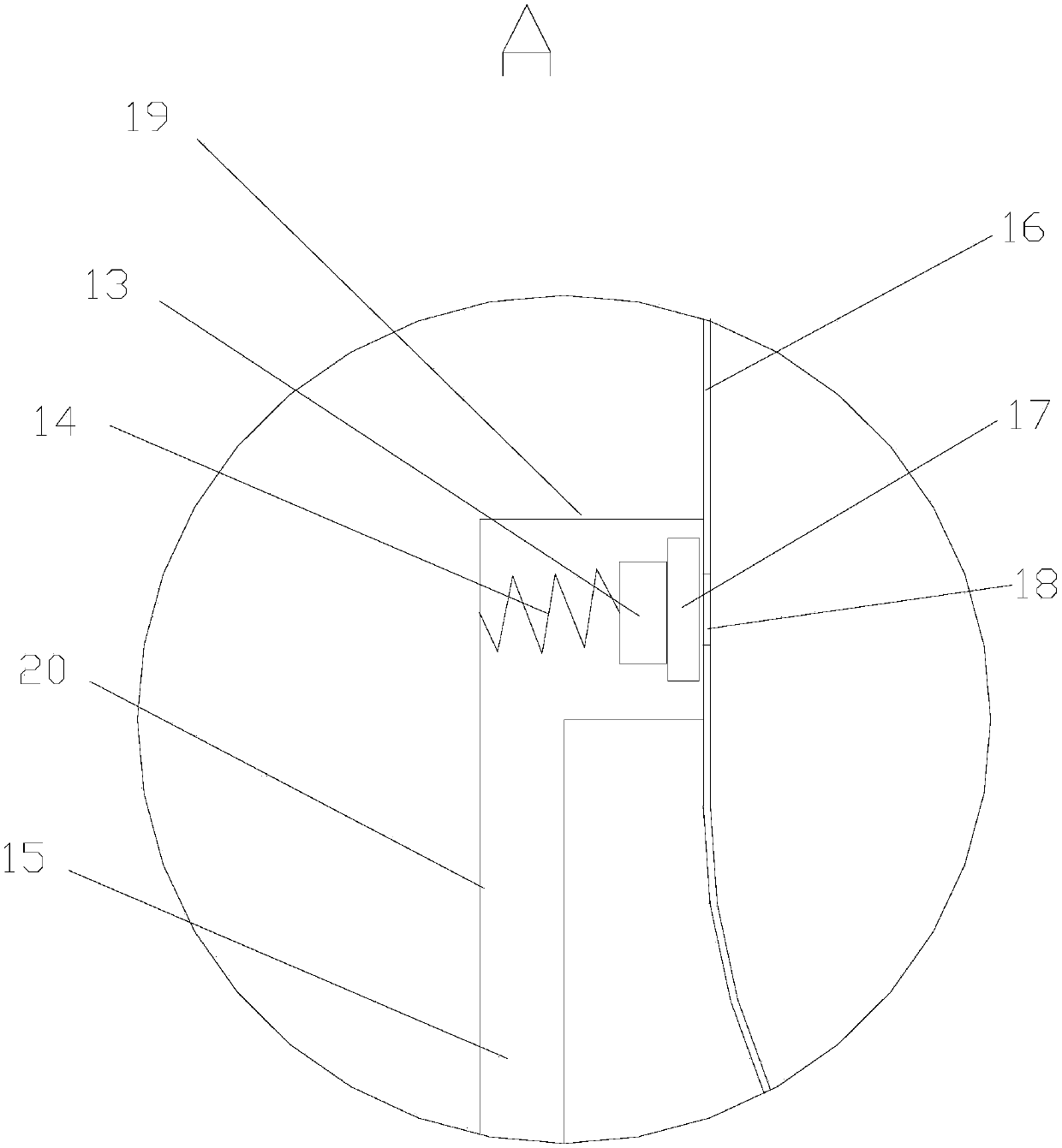

[0042] Such as figure 2 As shown, a centrifugal valve is introduced in this embodiment. The centrifugal valve includes an elastic seal 17, a counterweight 13, a spring 14 and a fixing member. The elastic seal 17 is correspondingly blocked in the opening 18 from the outside to the inside. At the position, the outer end of the elastic sealing member 17 is connected with the fixing member via the spring 14, and the fixing member is fixedly connected with the wall 16 of the washing tub, and the elastic sealing member 17 is equipped with a counterweight 13.

[0043] In this embodiment, the fixing part is the water outlet pipeline 15, the water outlet pipeline 15 includes a horizontal extension section 19 and a vertical extension section 20, the left end of the horizontal extension section 19 communicates with the opening 18, and the right end communicates with the vertical extension section 20. The upper end is connected, and the lower end of the vertical extension section 20 is c...

Embodiment 3

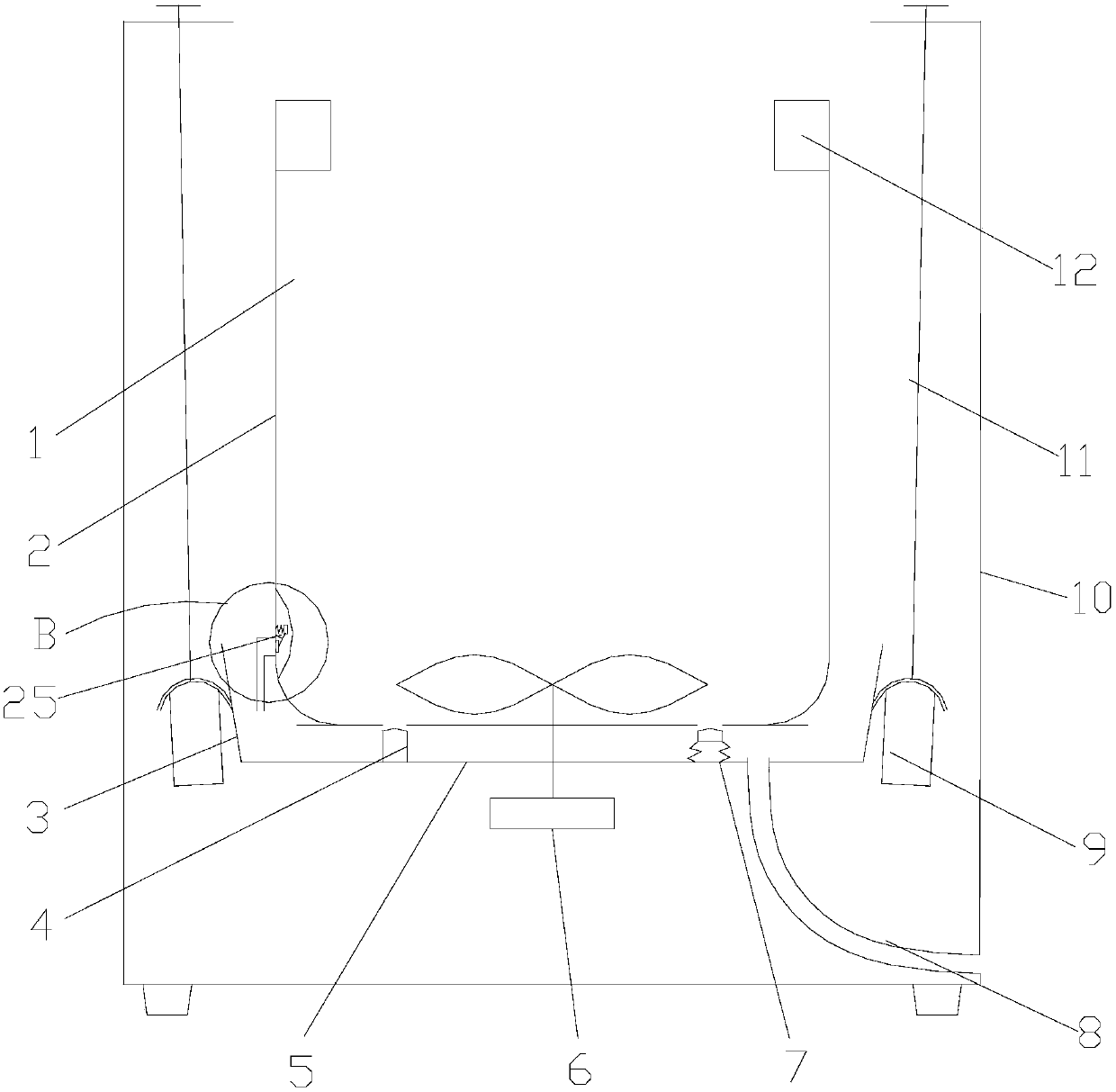

[0049] In this embodiment, the wall of the washing tub 2 gradually increases in diameter from the upper and lower ends to the direction of the opening 18, and the opening 18 is located on the horizontal cross-section of the largest diameter of the washing tub 2. During the high-speed spin dehydration process of the washing machine, the washing tub 2. Under the action of centrifugal force, the internal water flow converges and flows toward the opening 18, which facilitates the discharge of washing water and improves the efficiency of dehydration of clothes.

[0050] preferred, such as figure 1 As shown, the wall of the washing bucket 2 is a tapered bucket whose diameter gradually increases from top to bottom, and the opening 18 is arranged at the lowest part of the wall of the washing bucket 2, so that the washing water in the washing bucket 2 is blown by centrifugal force. When converging and flowing to the opening, gravity provides flow power to the washing water, assisting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com