Minimally invasive incision and tension reduction device for compartment syndrome

A syndrome and fascia technique, applied in the mechanical field, can solve problems such as deep fasciotomy that is difficult to control and easy to damage blood vessels, nerves, muscle soft tissues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

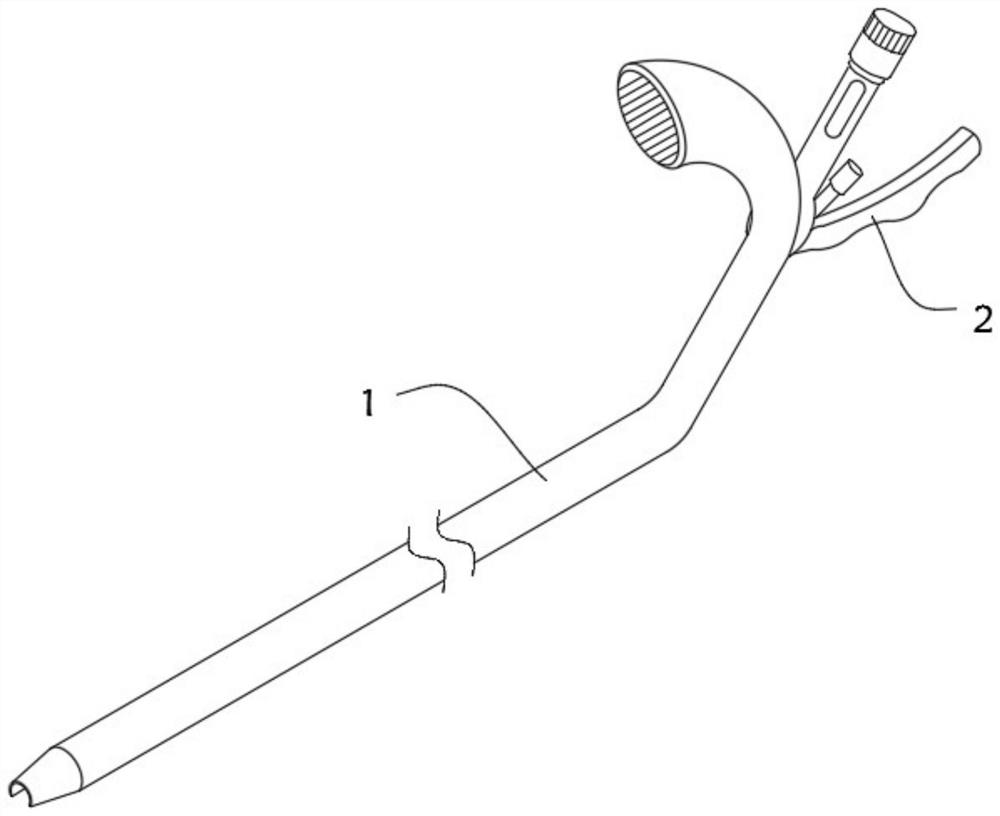

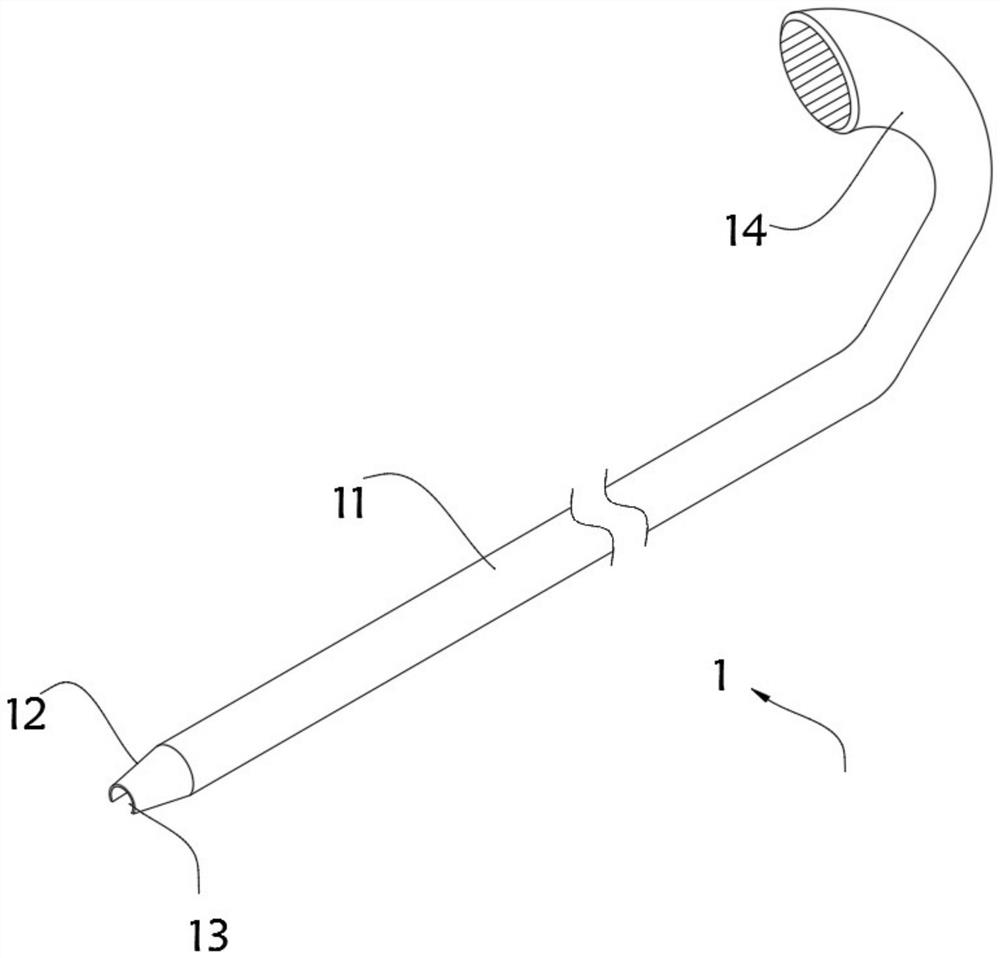

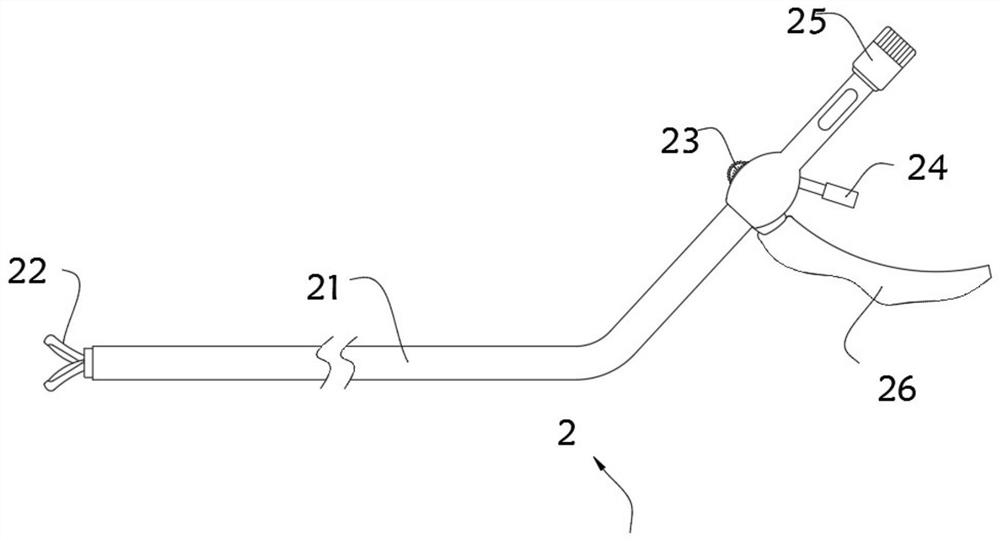

[0046] On the one hand, the present invention provides minimally invasive incision and tension reduction instruments for compartment syndrome, such as Figure 1-Figure 6 As shown, it includes an outer tube body 1 and an operating tube body 2 installed inside the outer tube body 1, the outer tube body 1 includes a sleeve 11, one end of the sleeve 11 is equipped with a chuck 12, and the other end of the sleeve 11 is provided with a handle The holding head 14, the bottom of the casing 11 and the clamping head 12 are all provided with strip grooves 13, the operating pipe body 2 includes an inner pipe 21, one end of the inner pipe 21 is provided with a heading scissors 22, and the inner pipe 21 is provided with a The adjusting tooth 23 of the opening angle of the heading scissors 22 and the safety lever 24 for fixing the opening angle of the heading scissors 22, a knife seat 27 is installed on one end of the heading scissors 22, and the heading scissors 22 includes a pair of knife r...

Embodiment 2

[0054] As the second embodiment of the present invention, in order to facilitate the adjustment of the opening angle of the heading scissors 22, the inventors improved the adjustment tooth 23, as a preferred embodiment, such as Figure 7-Figure 9 As shown, a transmission tooth 231 is installed on the side of the inner tube 21 close to the adjustment tooth 23, the outer wall of the adjustment tooth 23 is provided with an angle dial 232, the outer wall of the transmission tooth 231 is equipped with a rotating shaft 233, and the outer wall of the rotating shaft 233 is covered with Clockwork spring 234, the outer wall of the rotating shaft 233 is annularly wound with a first pulling rope 235, one end of the bumper 24 is equipped with a clamping plate 241, a plurality of clamping teeth 242 are installed on the clamping plate 241, the adjusting gear 23 and the transmission gear 231 engage.

[0055] In this embodiment, the outer wall of the inner tube 21 is provided with a notch for ...

Embodiment 3

[0061] As a third embodiment of the present invention, in order to facilitate the adjustment of the extension length of the heading scissors 22, the inventors improved the adjustment head 25, as a preferred embodiment, such as Figures 11 to 12 As shown, the inner tube 21 is also provided with an adjusting head 25 for adjusting the extension length of the heading scissors 22, a transmission shaft 251 is installed on one end of the adjusting head 25, and a ball screw nut 252 is installed on the side wall of the knife seat 27. The ball screw nut 252 is provided with a ball screw 253, and a connector 254 is installed between the ball screw 253 and the transmission shaft 251. The connector 254 includes a mounting seat 255, and rotating shafts 256 are respectively installed on both sides of the outer wall of the mounting seat 255. A pair of baffle plates 257 are arranged in the seat 255, and a mounting plate 258 is arranged between the two baffle plates 257. The inner wall of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com