Clamp mounting piece

A technology of mounting parts and clips, which is applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problem of difficult contact between clips and clamped objects, and achieve the effect of fast and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

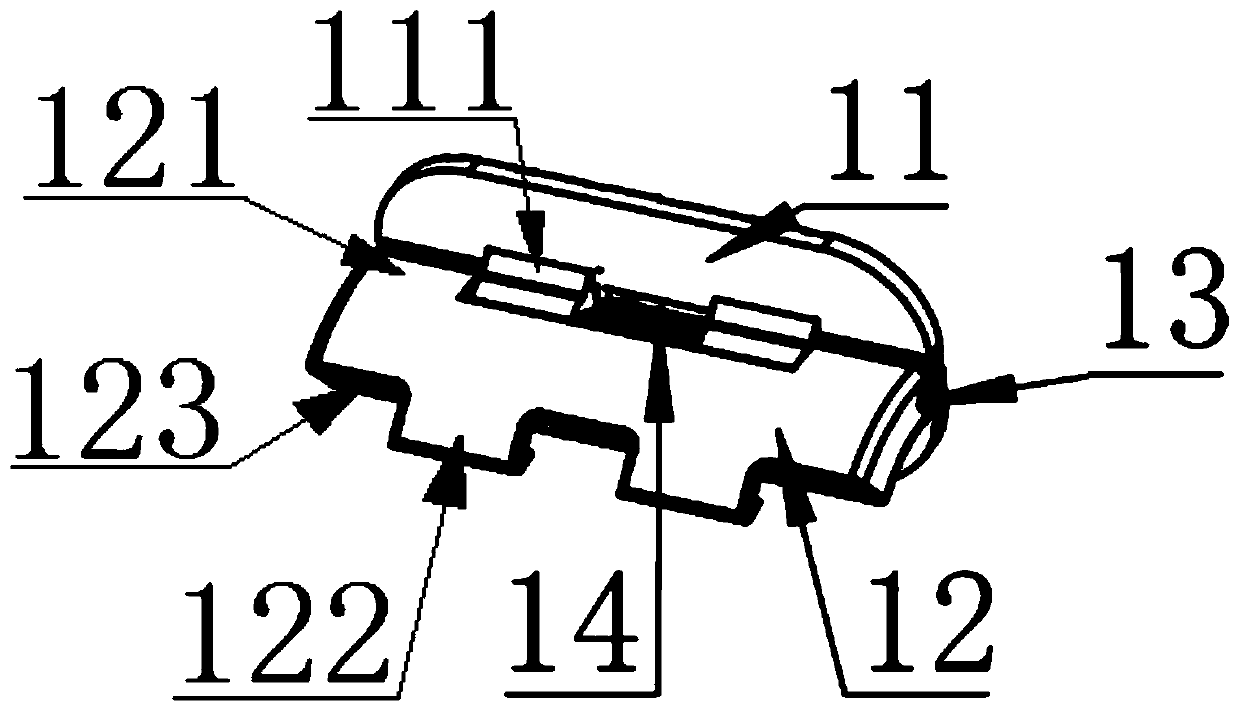

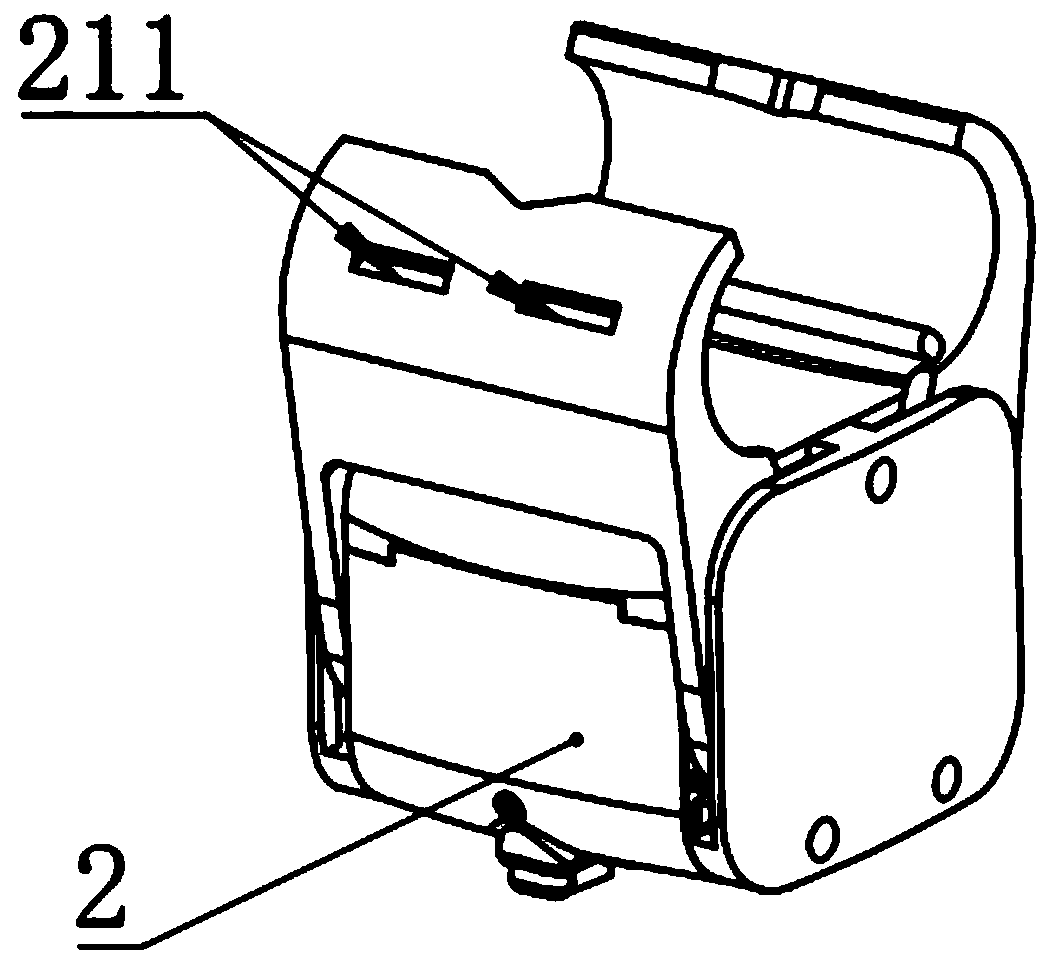

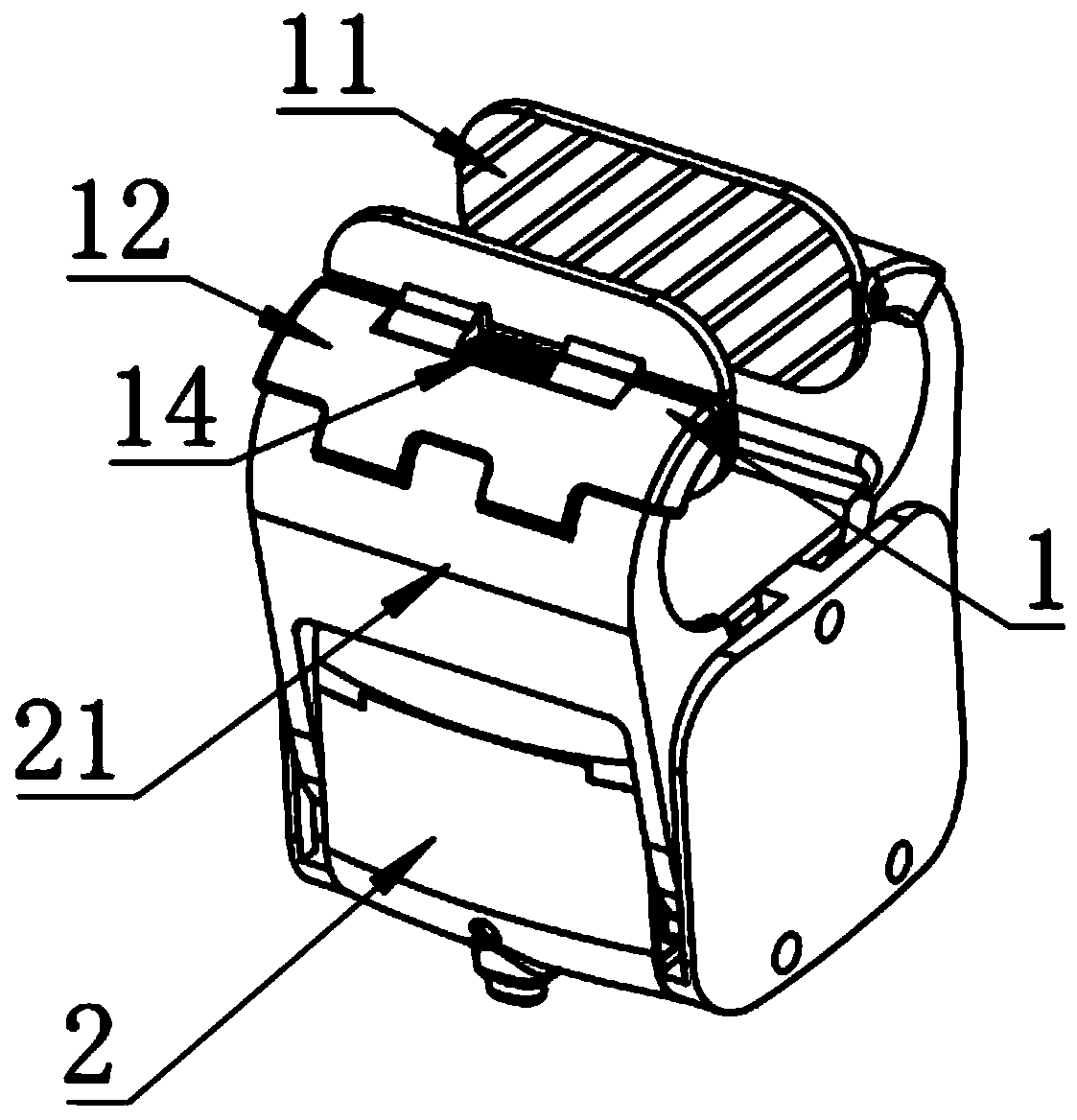

[0023] Such as figure 1 — Figure 4 As shown, the clip mounting part provided by this specific embodiment mainly includes: a clamping plate 11 , a metal shaft 13 , a mounting sleeve 12 , and a torsion spring 14 . Wherein, the surface of the clamping surface of the clamping plate 11 has slanted lines. In order to increase the friction of the clamping surface, two first protrusions 111 with through holes protrude from the back perpendicular to the clamping surface, and the through holes are provided for the metal shaft. 13; the side of the mounting sleeve 12 close to the clamping plate 11 has two protruding second protrusions 121 with through holes, the through holes are also for the metal shaft 12 to be loaded, and the two sides of the clamping plate 11 A first bump 111 is located between the two second bumps 121 of the installation sleeve 12, and the metal shaft 13 passes through the through holes of the first bump 111 and the second bump 121 to clamp the plate 11 and the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com