Can-making drying equipment with limiting gap adjustable

A technology of drying equipment and gap, which is applied in the field of can-making drying equipment with adjustable limit gap, which can solve the problems that the drying process of cans with different diameters cannot be satisfied, and achieve the effect of simple structure, low cost and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

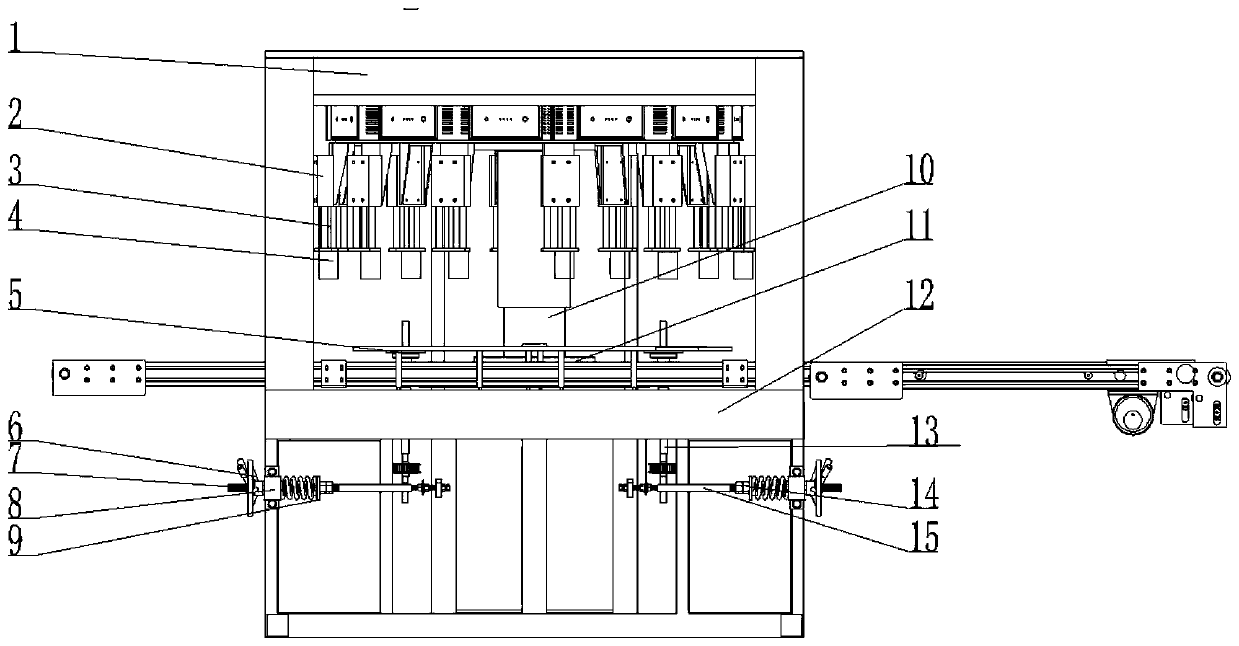

[0025] Implementation case 1: Canning drying equipment is a kind of drying equipment after welding food cans and milk powder cans. In order to meet the needs of the can drying process, two front and rear guiding devices are usually installed on the conveyor belt to dry the cans. For dry processing, the guide device usually includes guide wheels and transmission shafts to guide and limit the direction of the cans. However, the transmission shaft of this limit guide device is usually fixed on the frame. Once it is necessary to process cans of different sizes, It is necessary to change the diameter of the guide wheel so that the guide wheel can provide better guidance for the cans. This design structure makes it impossible to meet the drying process for cans with different diameters. At present, designers urgently need an adjustable limit. Can making and drying equipment with space gap.

[0026] In order to solve the technical problem in the prior art that the drying process of c...

Embodiment example 2

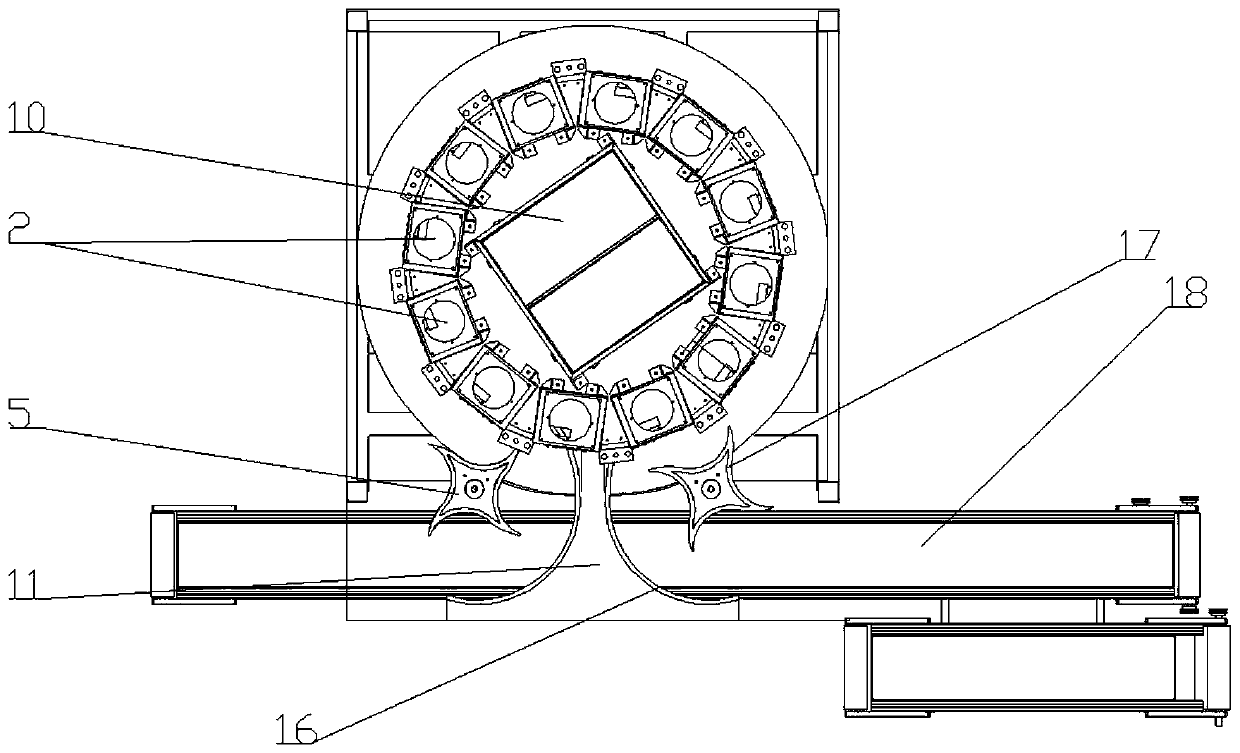

[0028] Implementation Case 2: If figure 2 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. The two ends of the transmission belt are connected with a driving wheel and a driven wheel. The two ends of the transmission drive are symmetrically provided with guide assemblies. The guide assemblies include a transmission shaft 13 and guide wheels 5. The guide wheels 5 are of circular or square structure. The guide wheels 5 are recessed inward to form arc-shaped grooves 16. Guide plate 11 is set, and guide plate 11 two ends are sunken inwardly to form guide groove 17, and guide groove 17 is arc-shaped structure, and the upper end of main shaft 10 is connected with rotating disk 1, and rotating disk 1 lower end is provided with some telescopic cylinders 2.

[0029]According to the present invention, the jar is moved forward by one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com