Ultrasonic fluid measurement probe with ultrasonically welded base cap

A fluid measurement, base technology, used in liquid/fluid solid measurement, blood flow measurement device, measurement device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

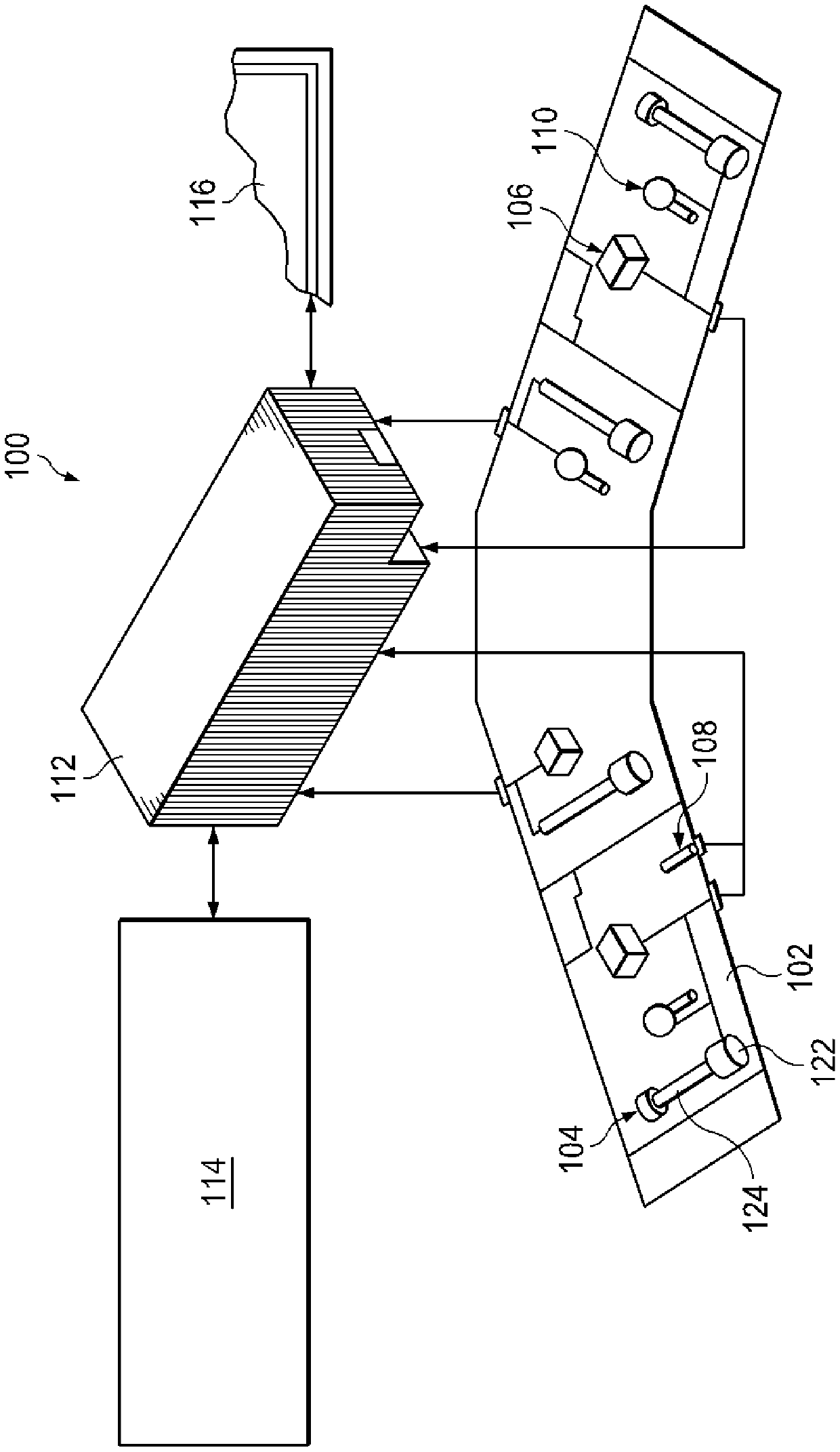

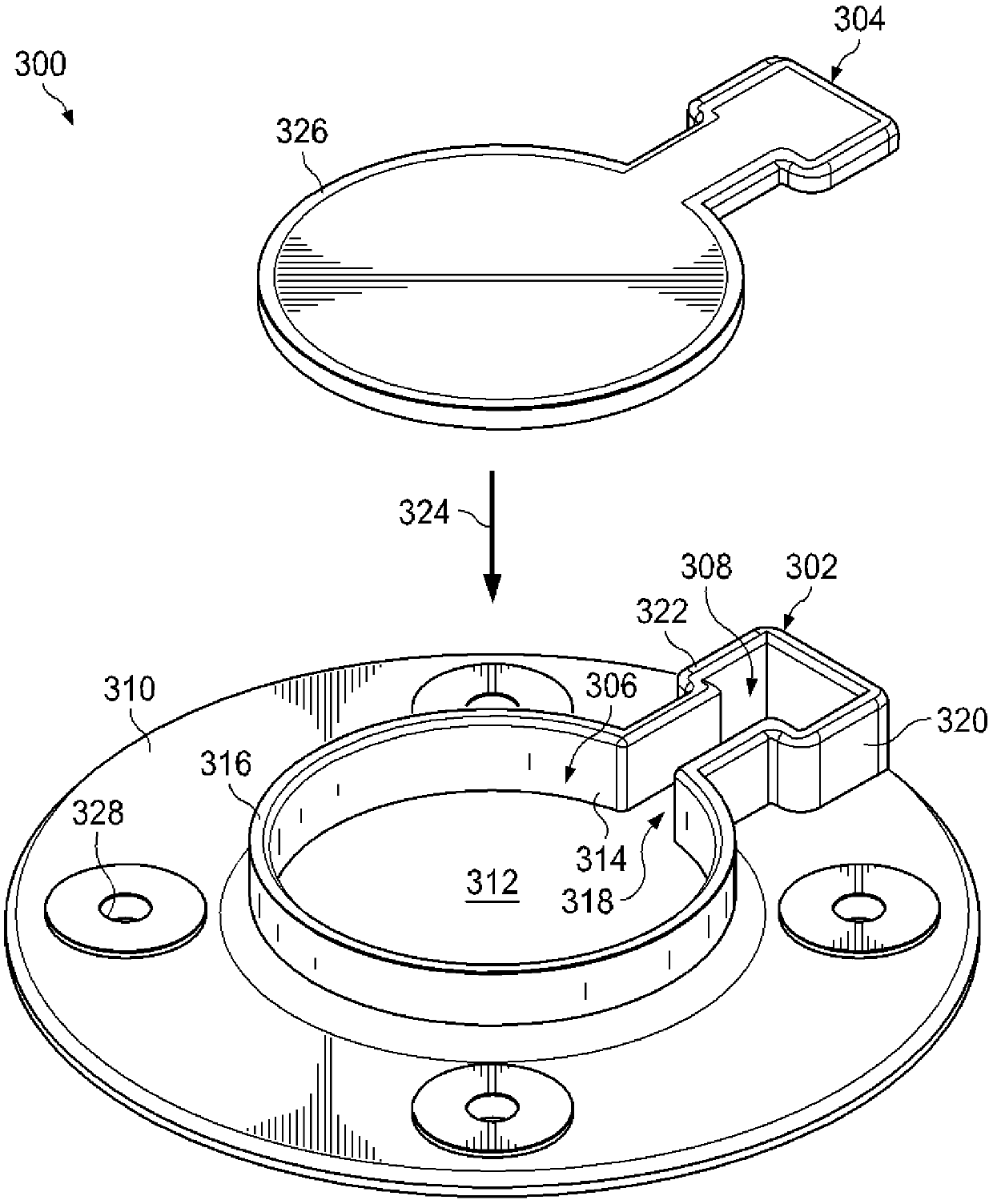

Image

Examples

Embodiment Construction

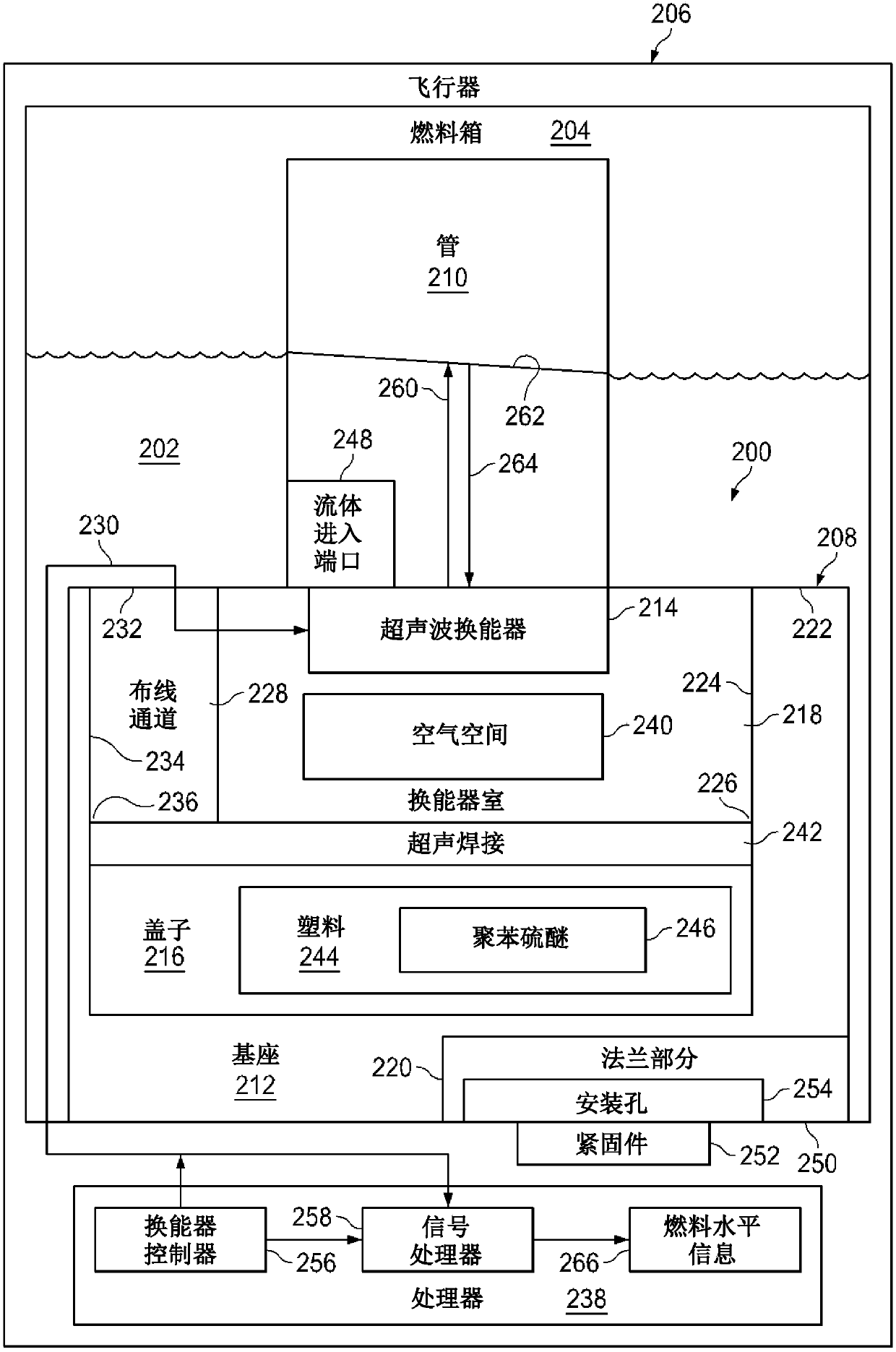

[0018] The illustrative embodiments recognize and take into account different situations. For example, the illustrative embodiments recognize and take into account that ultrasonic measurement probes in fuel tanks on aircraft may often be subject to extreme environmental conditions, which may cause them to prematurely need to be repaired or replaced. When an ultrasonic fuel probe in an aircraft fuel tank needs to be repaired or replaced, the aircraft needs to be taken out of service and maintenance personnel may need to perform fuel tank access. Access to the fuel tank by maintenance personnel to repair or replace the fuel probe requires the tank to be emptied and cleaned. In many cases, repairing or replacing an ultrasonic fuel probe in an aircraft's fuel tank can require up to two days of downtime during which time the aircraft is out of operation. Such downtime can be very expensive for airlines or other aircraft operators.

[0019] There may be a considerable number of ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com