Construction method for engine testing working condition

A construction method and tester technology, applied in the field of transportation, which can solve problems such as deviation of certification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

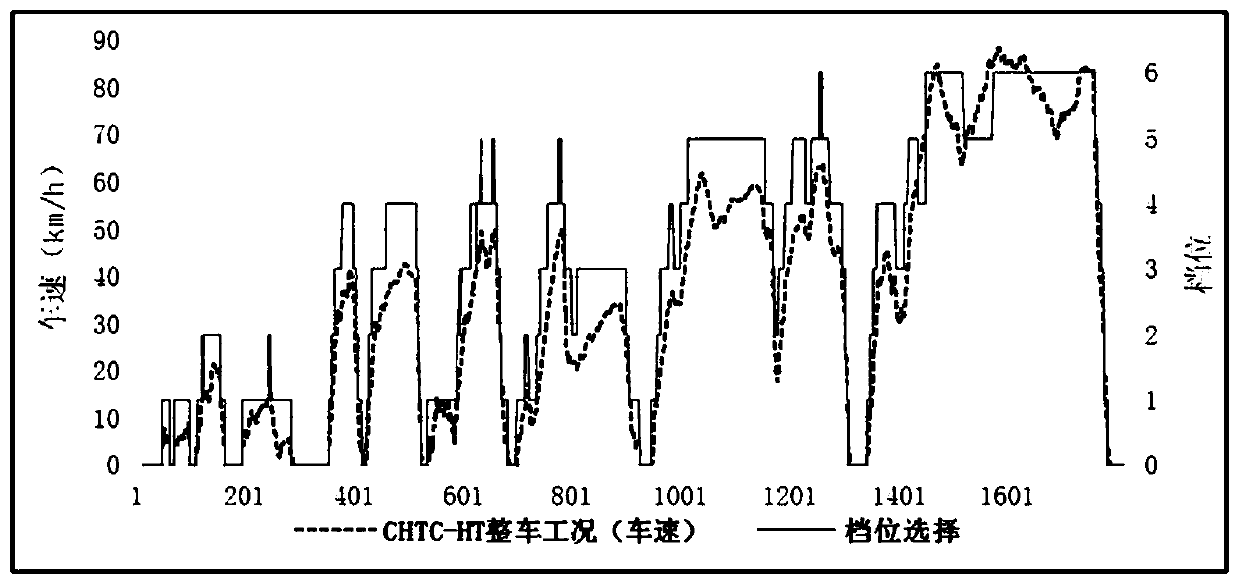

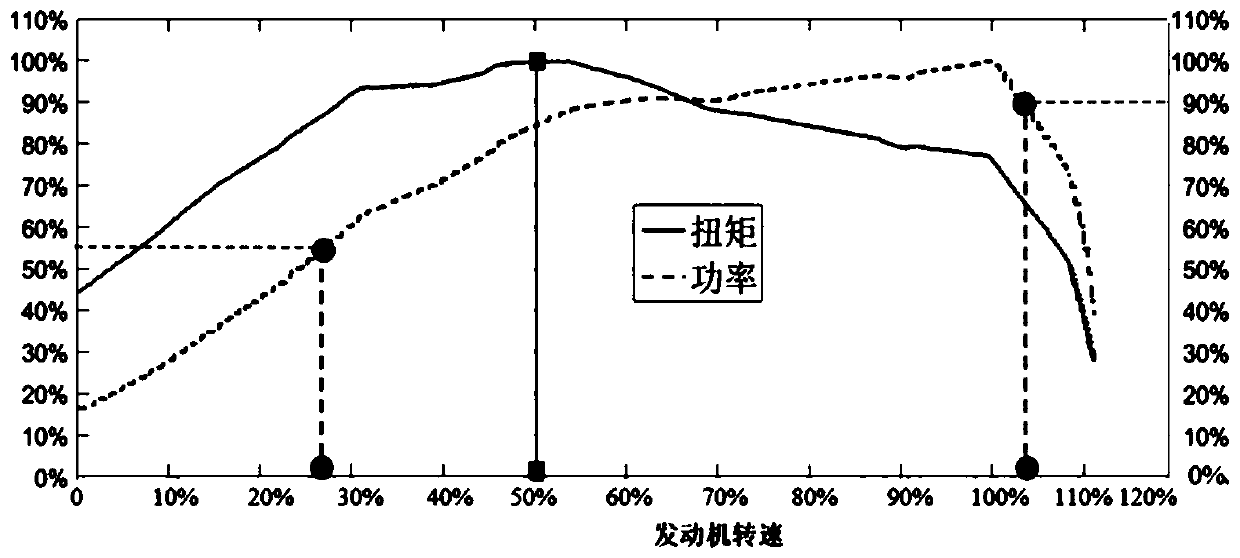

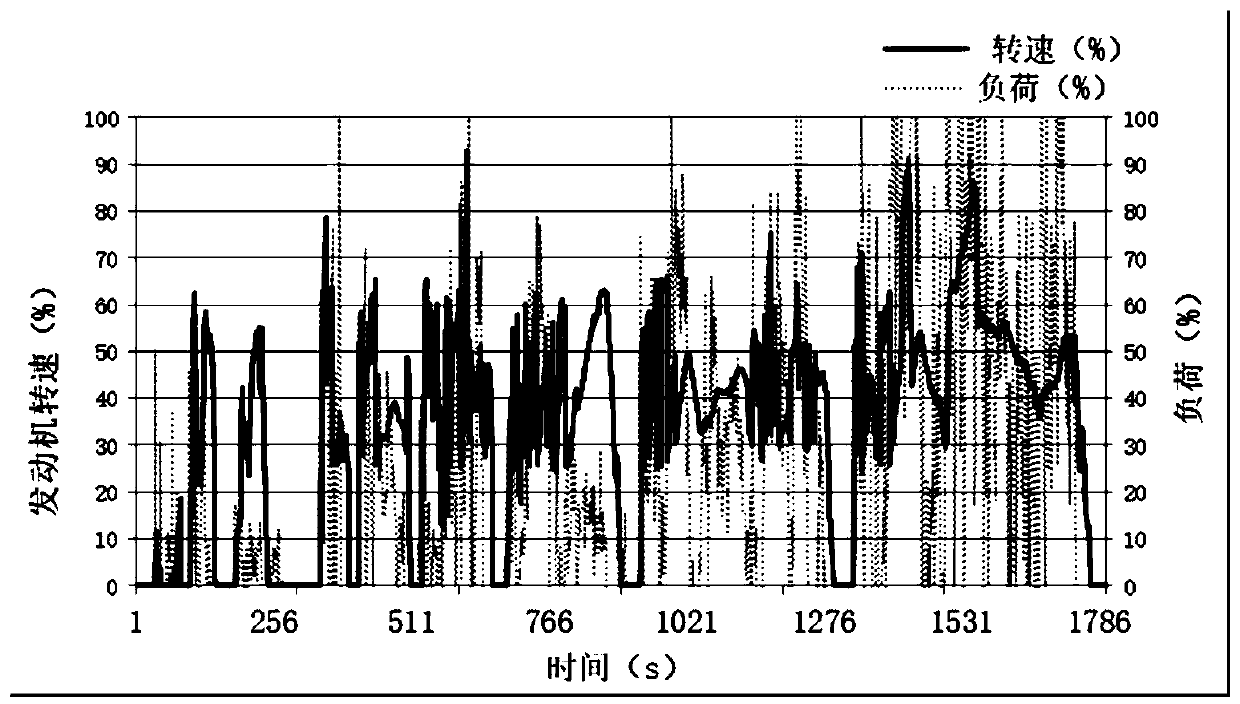

[0016] In this embodiment, the proposed engine test conditions include transient test conditions and steady-state test conditions. In the transient test conditions, the transient operating point is composed of engine speed and load percentage.

[0017] In this example, the transient test conditions are constructed based on the CHTC-HT operating cycle with various characteristic parameters at the average level in the CHTC system; a heavy-duty commercial vehicle with a maximum design total mass of 18000kg and a rated power of 134kw is adopted. To illustrate the process of establishing the test conditions, it is referred to as vehicle A in this embodiment for ease of description.

[0018] When establishing transient test conditions, the steps include:

[0019] S101. Using the driving resistance curve of vehicle A provided by the manufacturer, calculate the vehicle power corresponding to 1800 operating mode points in the CHTC-HT operating mode cycle. The power calculation formula is:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com