Elastic automatic crimping device

A crimping device, automatic technology, applied in the direction of the measuring device shell, etc., can solve the problems of precise positioning, inability to FPC, FPC damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

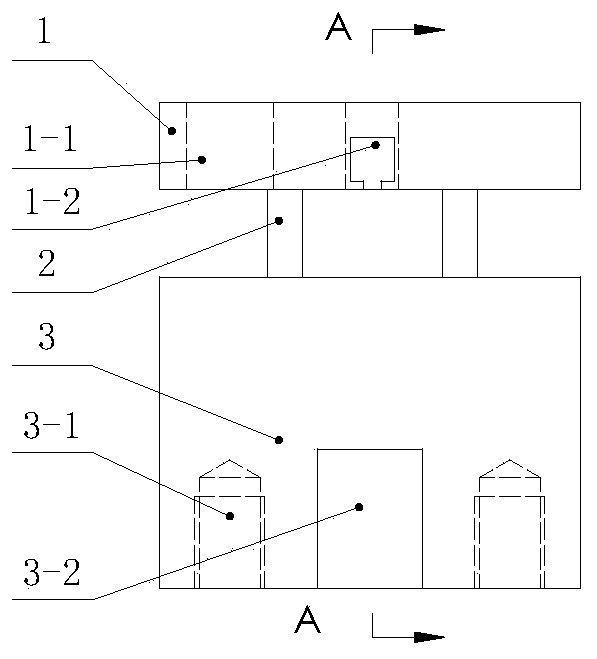

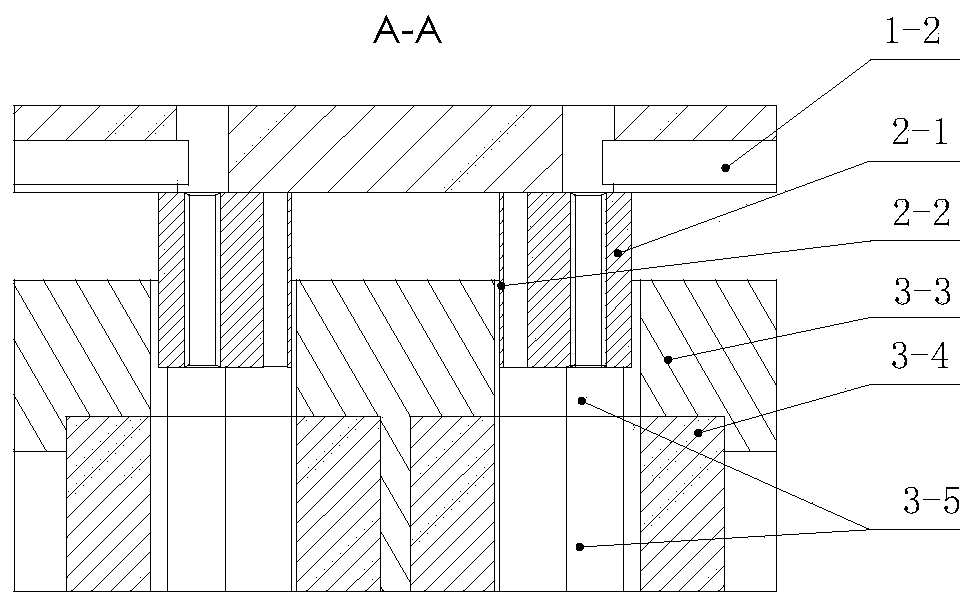

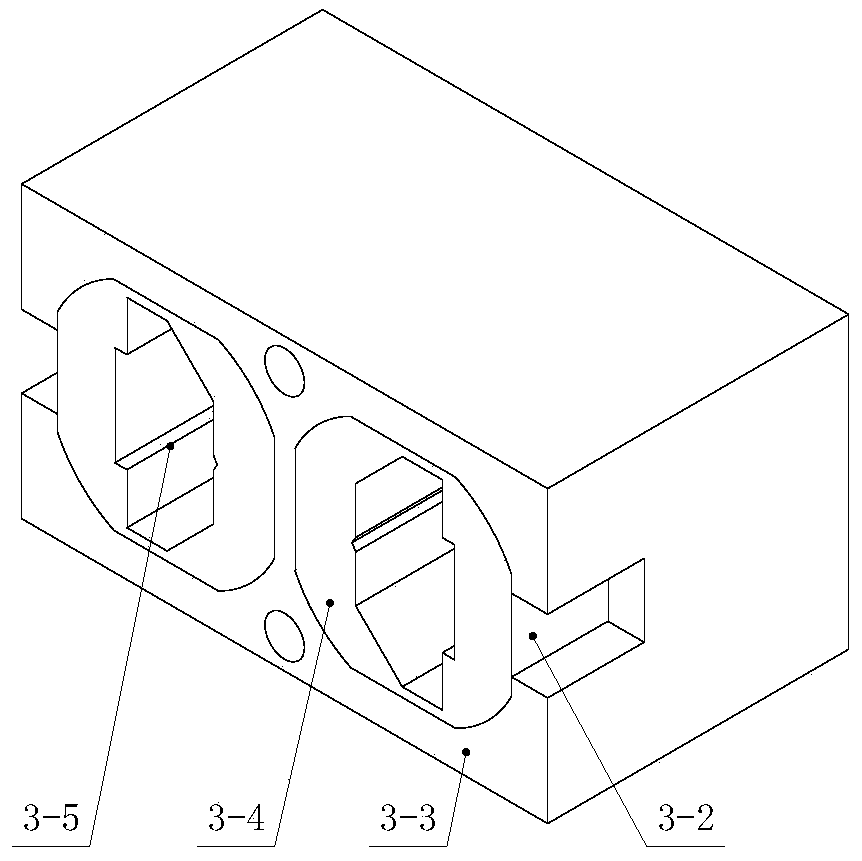

[0029] This embodiment provides an elastic automatic crimping device, such as Figure 1-3 As shown, it includes an indenter 1, a moving electrode 2, and a base 3.

[0030] The base 3 mainly includes an insulating matrix 3-3, a conductive copper column 3-4, and an on-off chute 3-5. The conductive copper column 3-4 is embedded in the insulating matrix 3-3, and the conductive copper column 3-4 The break groove 3-5 runs through the insulating base 3-3 and the conductive copper pillar 3-4.

[0031] A first wire is connected to the conductive copper column 3-4, and the first wire is used to connect to a lighting connector, and an FPC is inserted into the lighting connector.

[0032] The moving electrode 2 is connected with a second wire, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com