A heat dissipation control method, device and charging pile

A control method and charging pile technology, applied in temperature control, circuit devices, battery circuit devices, etc., can solve the problems of low system power utilization and lower output power, so as to reduce power consumption, improve utilization, and ensure high power output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

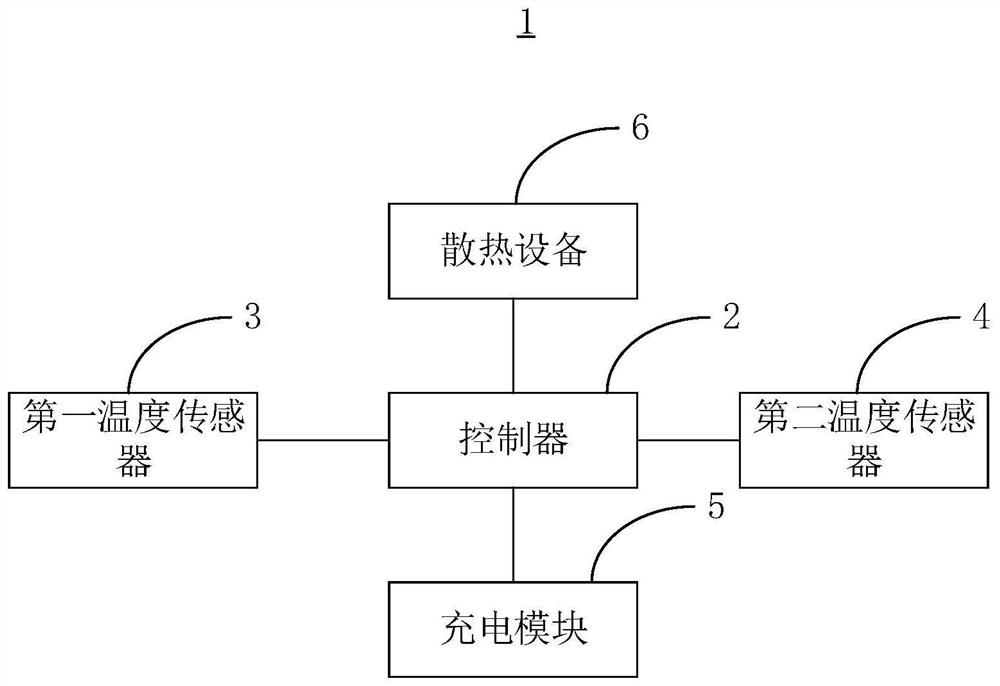

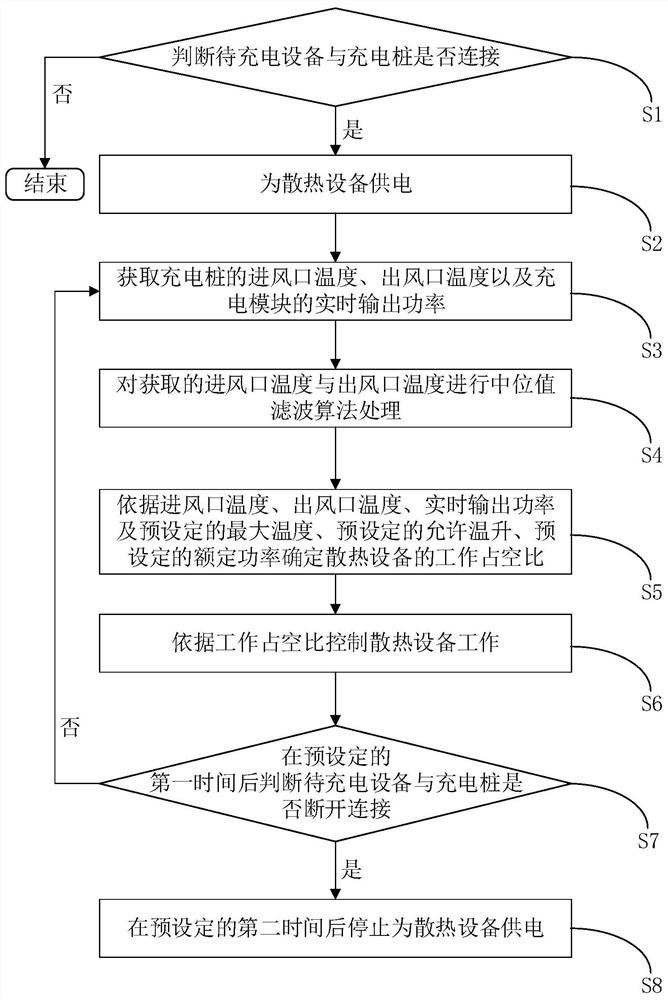

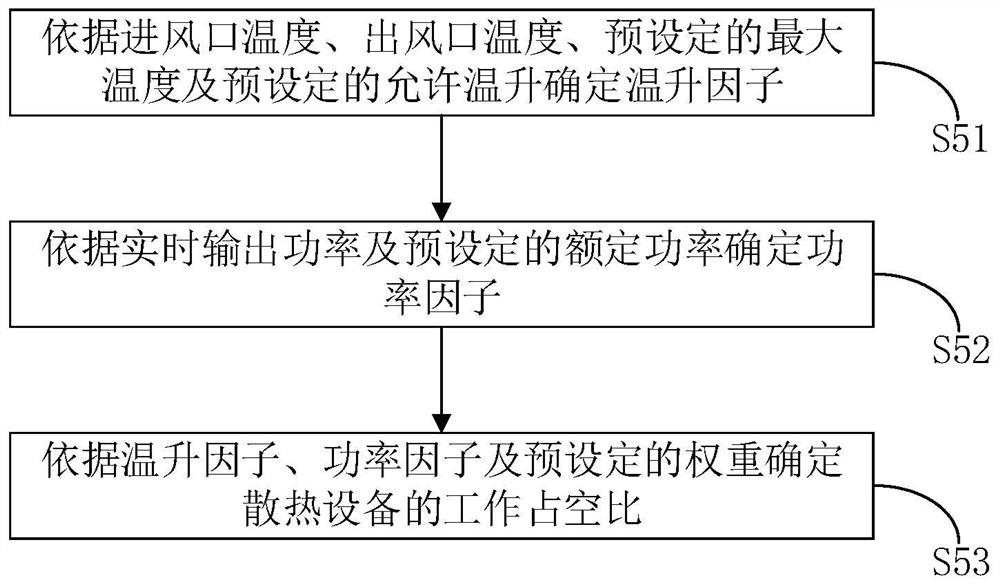

[0031] The embodiment of the present invention provides a heat dissipation control method, which is applied to the charging pile 1, please refer to figure 1 , the charging pile 1 includes a controller 2, a first temperature sensor 3, a second temperature sensor 4, a charging module 5 and a cooling device 6, the controller 2 is connected with the first temperature sensor 3, the second temperature sensor 4, the charging module 5 and the The heat dissipation device 6 is electrically connected, the first temperature sensor 3 is used to obtain the temperature of the air inlet, and the second temperature sensor 4 is used to obtain the temperature of the air outlet. And, in this embodiment, the cooling device 6 is a fan, and its quantity can also be multiple, for example, the quantity of the fan is 3, meanwhile, the quantity of the charging module 5 can also be multiple, such as the quantity of the charging module 5 The number is also three, of course, in some other embodiments, the ...

no. 2 example

[0079] see Figure 6 , is a schematic diagram of functional units of a heat dissipation control device 7 provided by an embodiment of the present invention. It should be noted that the basic principles and technical effects of the heat dissipation control device 7 provided in this embodiment are the same as those of the above-mentioned embodiments. corresponding content in the example. The heat dissipation control device 7 includes:

[0080] The judging unit 8 is configured to judge whether the device to be charged is connected to the charging pile 1 or not.

[0081] It can be understood that S1 can be executed by the judging unit 8 .

[0082] The power supply unit 9 is used to supply power to the cooling device 6 .

[0083] It can be understood that S2 can be executed by the power supply unit 9 .

[0084] The information acquisition unit 10 is configured to acquire the temperature of the air inlet and outlet of the charging pile 1 and the real-time output power of the ch...

no. 3 example

[0104] The embodiment of the present invention also provides a charging pile. The charging pile includes a controller, a first temperature sensor, a second temperature sensor, a charging module, and a heat dissipation device. The controller is connected with the first temperature sensor, the second temperature sensor, the charging The module and the cooling device are electrically connected, the first temperature sensor is used to obtain the temperature of the air inlet, and the second temperature sensor is used to obtain the temperature of the air outlet. Among them, the controller is used to supply power to the cooling device when the device to be charged is connected to the charging pile; and obtain the air inlet temperature, the air outlet temperature of the charging pile, and the real-time output power of the power supply module; The air outlet temperature, real-time output power, preset maximum temperature, preset allowable temperature rise, and preset rated power determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com