Production equipment and production process of pole piece

A technology of production equipment and production process, which is applied in the field of pole piece production equipment and its production process, can solve the problems of easy breakage in the empty foil area, achieve the effects of reducing scrap rate, reducing production cost, and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

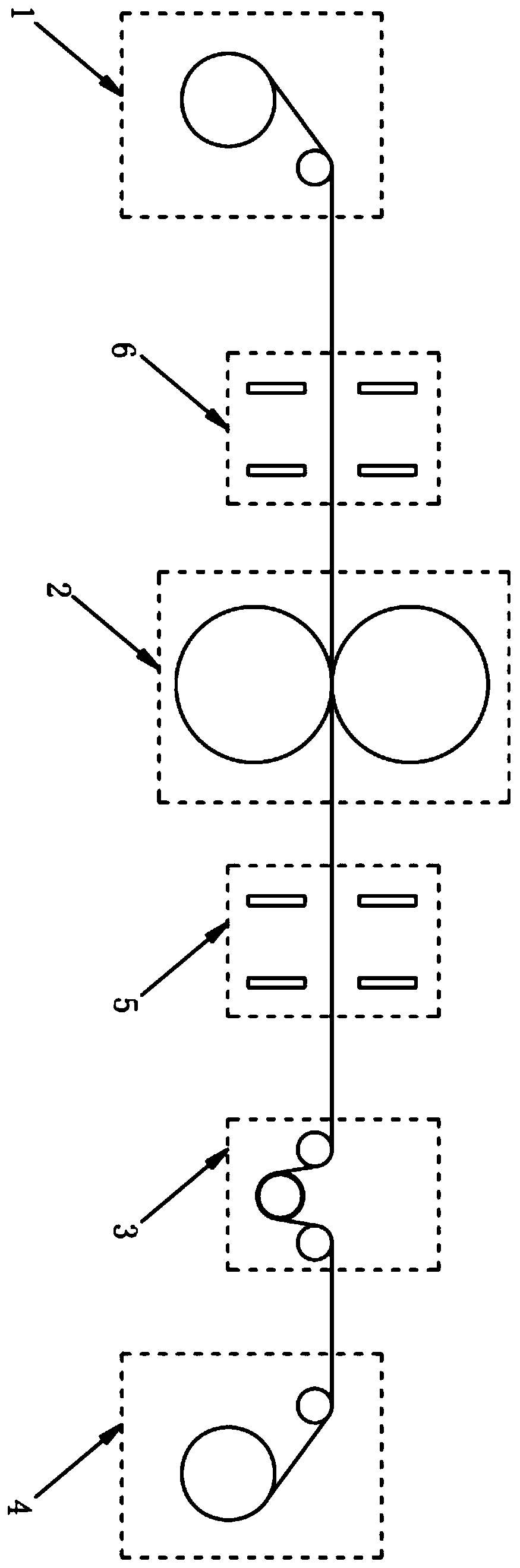

[0039] Such as figure 1 Shown, a kind of pole piece production equipment comprises:

[0040] Unwinding mechanism 1;

[0041] Preheating mechanism 6, the preheating mechanism 6 is used to preheat the empty foil area, the preheating mechanism 6 is set between the rolling mechanism 2 and the unwinding mechanism 1, and the preheating method is infrared preheating or electromagnetic induction through the heating column warm up.

[0042] Rolling mechanism 2, the rolling mechanism 2 is used for rolling the pole piece, the pole piece includes a film area with a film layer formed on its surface and an empty foil area without a film layer formed on its surface;

[0043] Stretching mechanism 3, which is used to stretch the pole piece;

[0044] winding mechanism 4; and

[0045] Heating mechanism 5, the heating mechanism 5 is used to heat the empty foil area, the heating mechanism 5 is arranged between the rolling mechanism 2 and the stretching mechanism 3, and the heating method is in...

Embodiment 2

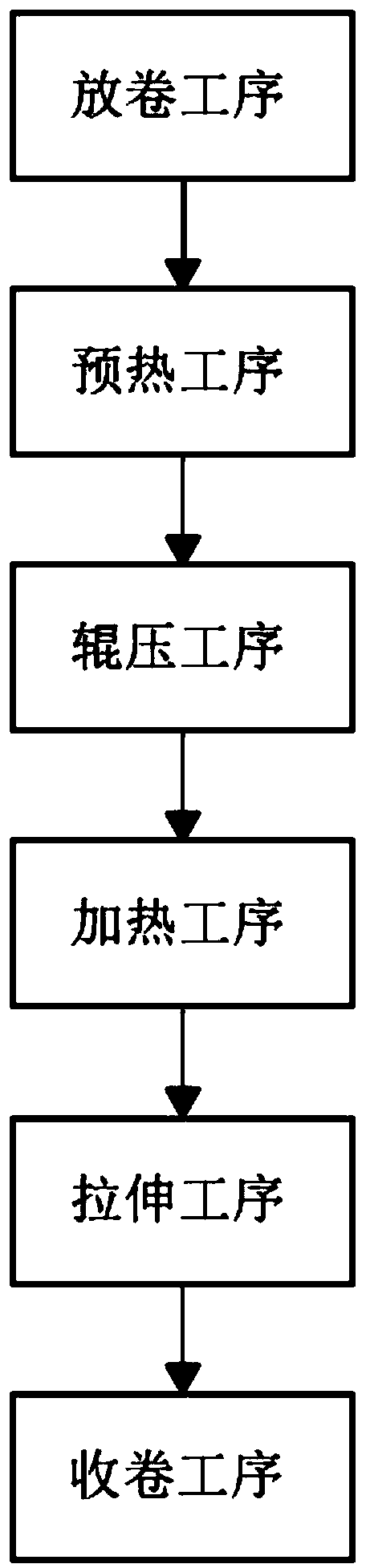

[0056] Such as figure 2 Shown, a kind of pole piece production technology comprises:

[0057] Unwinding process, unwinding the pole piece, the pole piece includes a film area with a film layer formed on its surface and an empty foil area without a film layer formed on its surface;

[0058] The preheating process is to preheat the empty foil area. The preheating temperature is 60~100°C, more preferably 70~90°C, and most preferably 80°C. The preheating method is infrared preheating or electromagnetic induction through the heating column warm up;

[0059] In the rolling process, the film area is rolled to extend the film area;

[0060] In the heating process, the empty foil area is heated, the heating temperature is 150-350°C, more preferably 250-320°C, most preferably 300°C, and the heating method is infrared heating or electromagnetic induction heating through the heating column;

[0061] Stretching process, stretching the empty foil area to extend the empty foil area;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com