Buckwheat rice grain slurry rubbing machine

A buckwheat grits and No. 1 technology, which is applied in the field of food processing and production machinery, can solve the problems of low temperature extraction, instant extraction, time-consuming and labor-intensive kneading process, and inaccurate concentration of juice, etc., to achieve consistent quality and taste , The design structure is simple and durable, and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

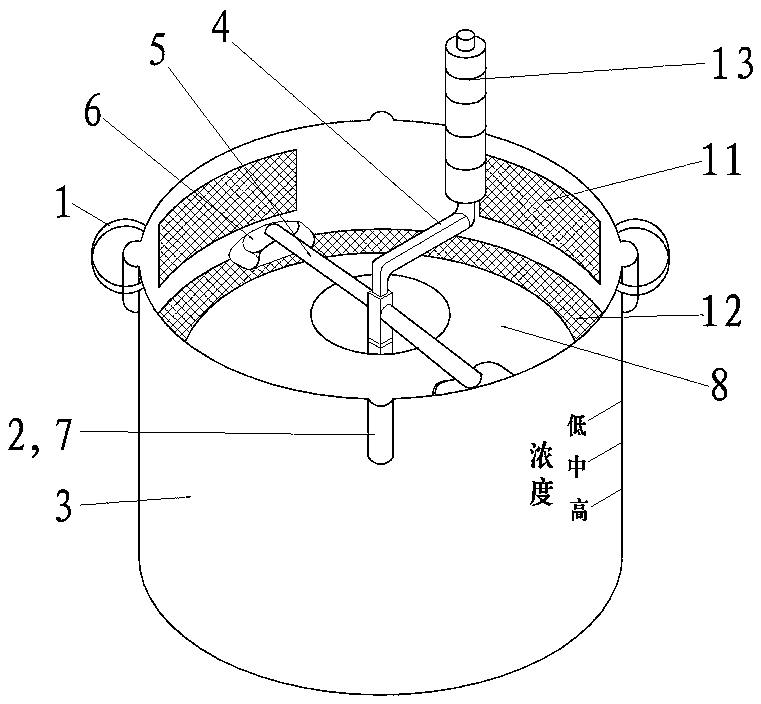

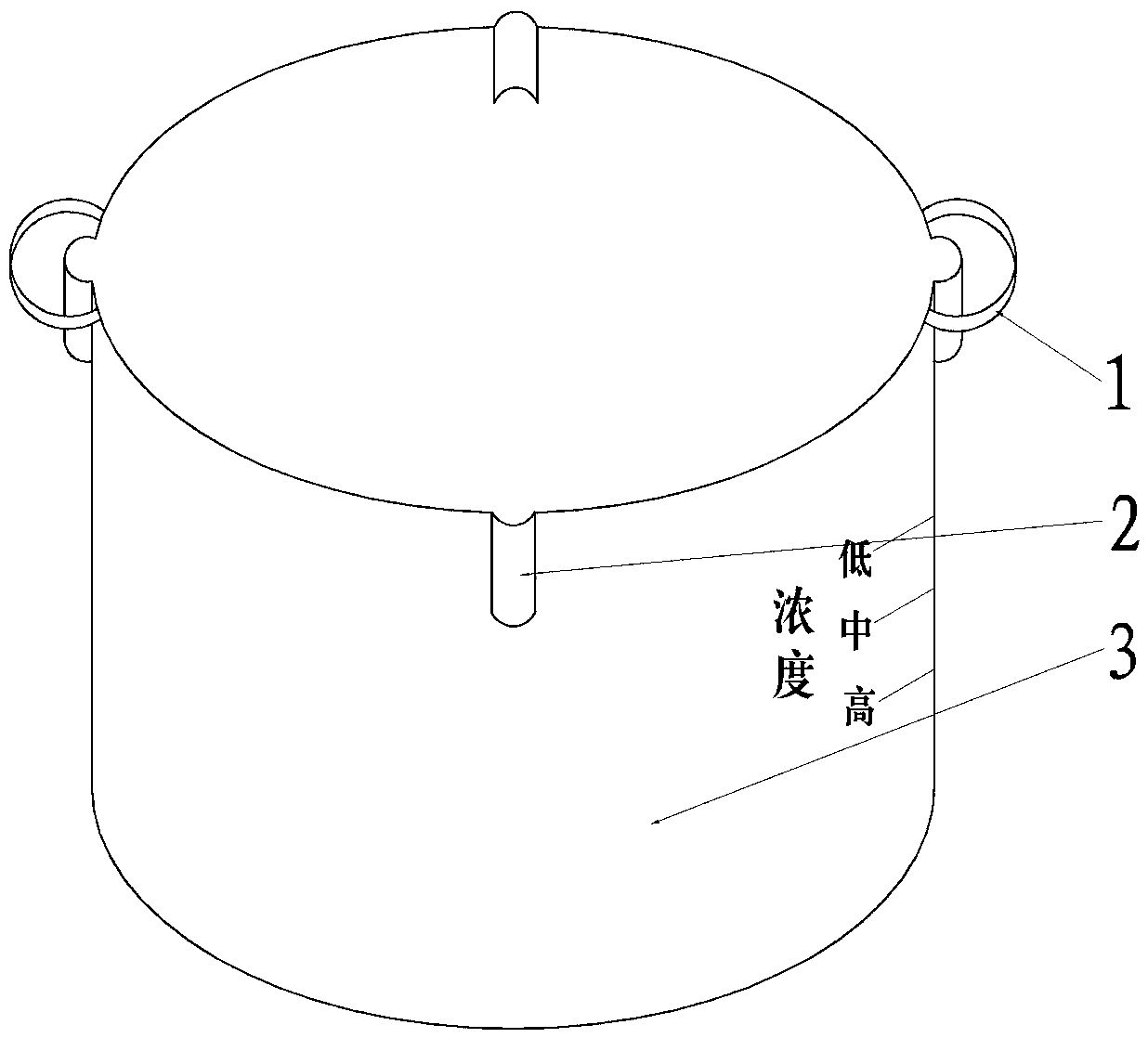

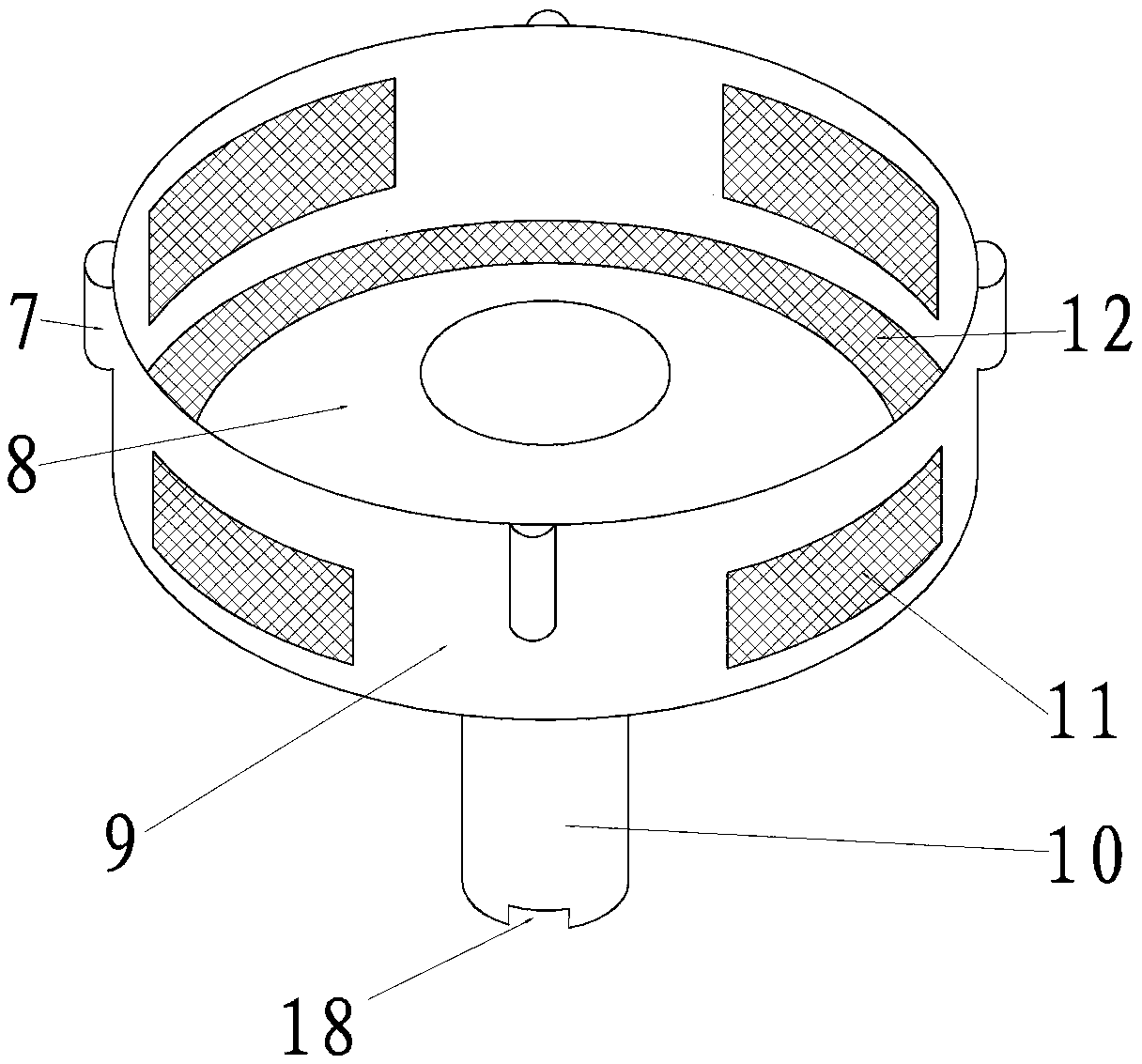

[0023] Such as Figure 1-8 , the composition of the present invention includes a cylinder body 3, a mesh screen 9, a positive-rotation and reverse-thrust set 14 for lifting the slurry to be arranged in the closed cover 21, a crank handle 4 for grinding buckwheat grits, a horizontal shaft 5, and a kneading hammer 6 Components; the cylinder 3 and the screen 9 are fixedly connected by the bolt 7 and the slot 2; the cylinder 3 is provided with a handle 1 and a transparent cover plate 19. The cylinder 3 is provided with a high, middle , Low concentration line. In this embodiment, the pin 7 is arranged on the outside of the screen 9, the slot 2 is arranged on the inside of the cylinder 3 corresponding to the pin 7, and the combination of the pin 7 and the slot 2 is set at least 3 pairs; the mesh 9 There are side sieves 11 and a circle of bottom sieves 12 o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap