Pre-stressed tension structure

A tensioning structure and prestressing technology, applied in the field of mechanical equipment, can solve problems such as disassembly first

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

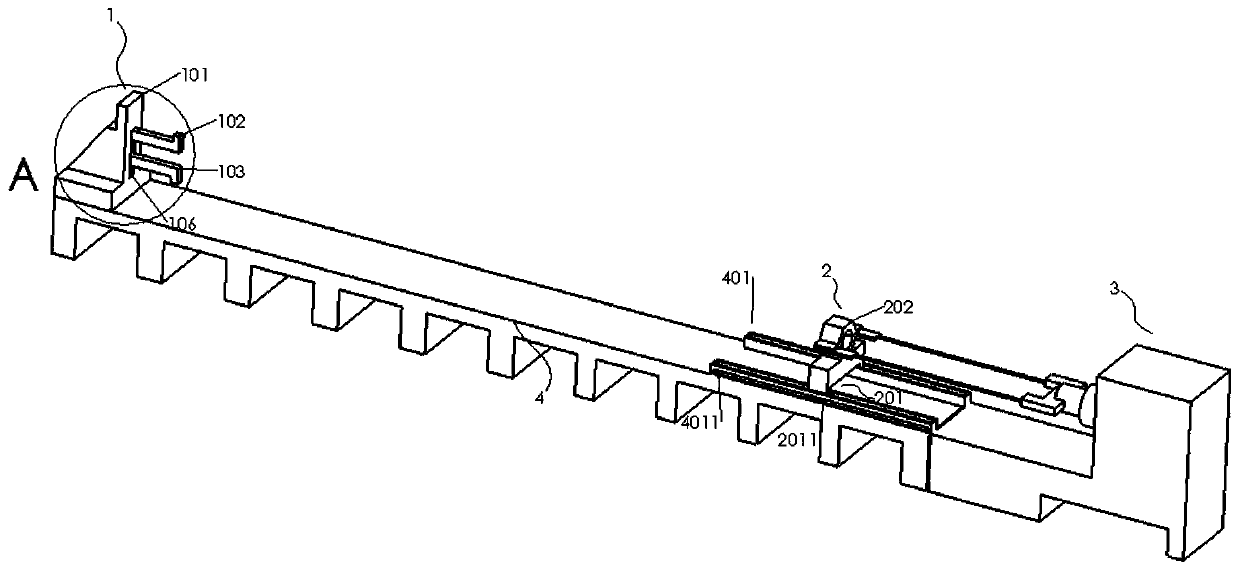

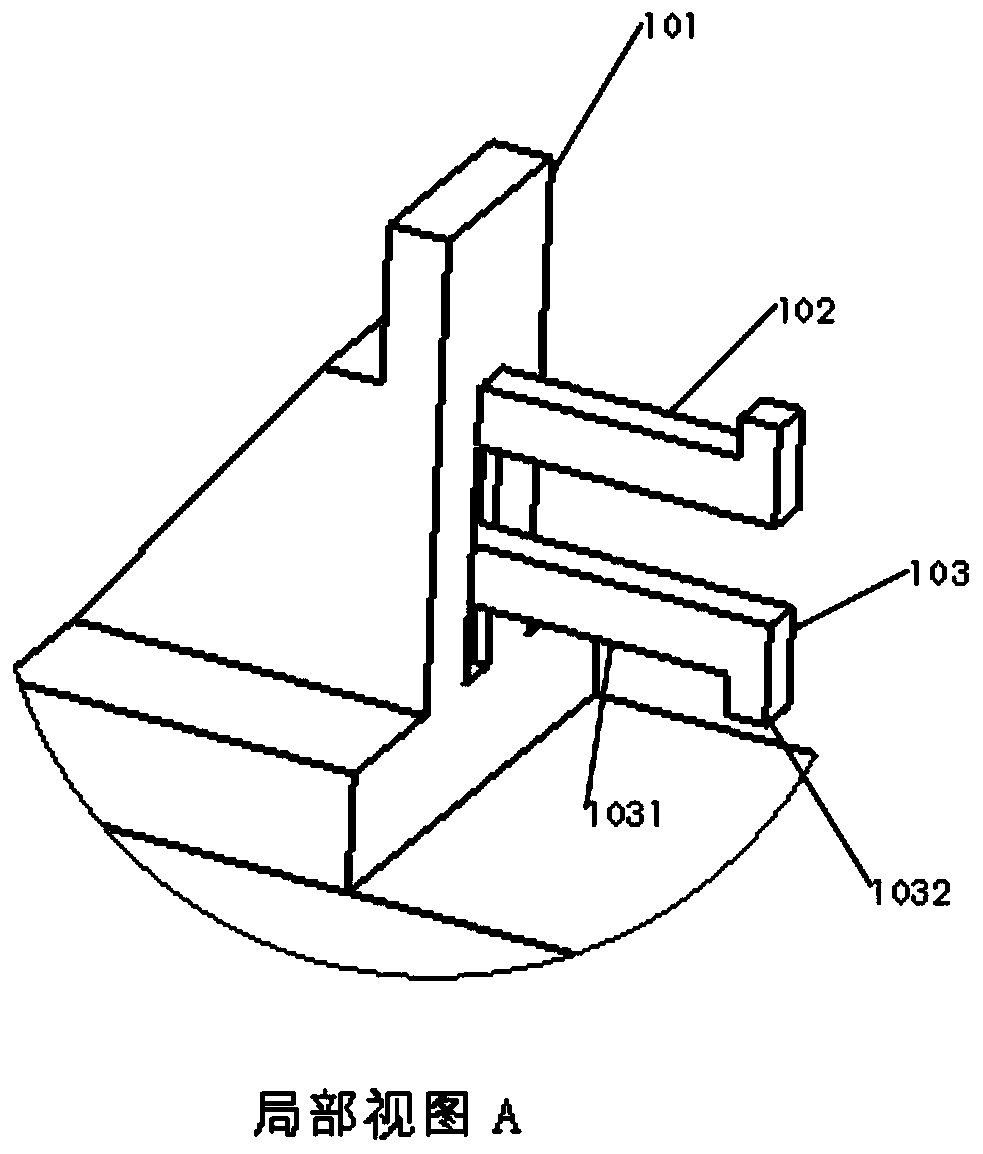

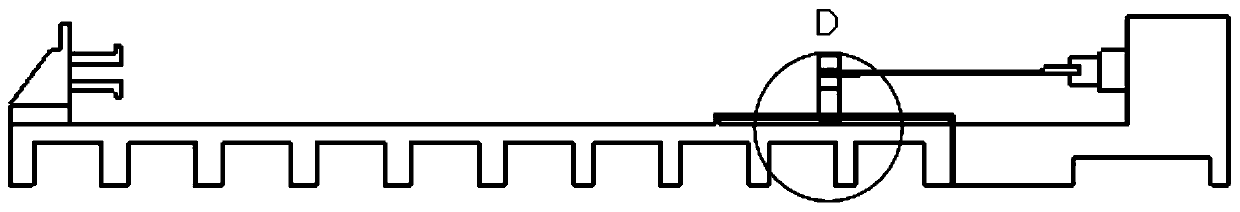

[0023] refer to Figure 1 to Figure 7 , a prestressed tension structure, including a fixed tooling 1, a mobile tooling 2 and a tensioning device 3, the fixed tooling 1, the mobile tooling 2 and the tensioning device 3 are arranged in a straight line, and the moving tooling 2 is located between the fixed tooling 1 and the tensioning device 3 Between the stretching devices 3, the stretching device 3 is fixedly connected with the mobile tooling 2, and the stretching of the stretching device 3 makes the mobile tooling 2 move along the line connecting the stretching device 3 and the fixed tooling 1. The prestressed tension structure also includes a fixed Table 4, the fixed tooling 1 is fixed on the fixed table 4 by bolts, the mobile tooling 2 is installed on the fixed table 4 through guide rails or without any constraints, and the stretching device 3 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com