Casting sand grinding device

A sand grinding and consistent technology, which is applied in the direction of casting molding equipment, manufacturing tools, cleaning/processing machinery of casting mold materials, etc., can solve the problems of low sand grinding efficiency and poor sand grinding effect, and achieve high sand grinding efficiency, Good grinding effect, increase the effect of rolling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

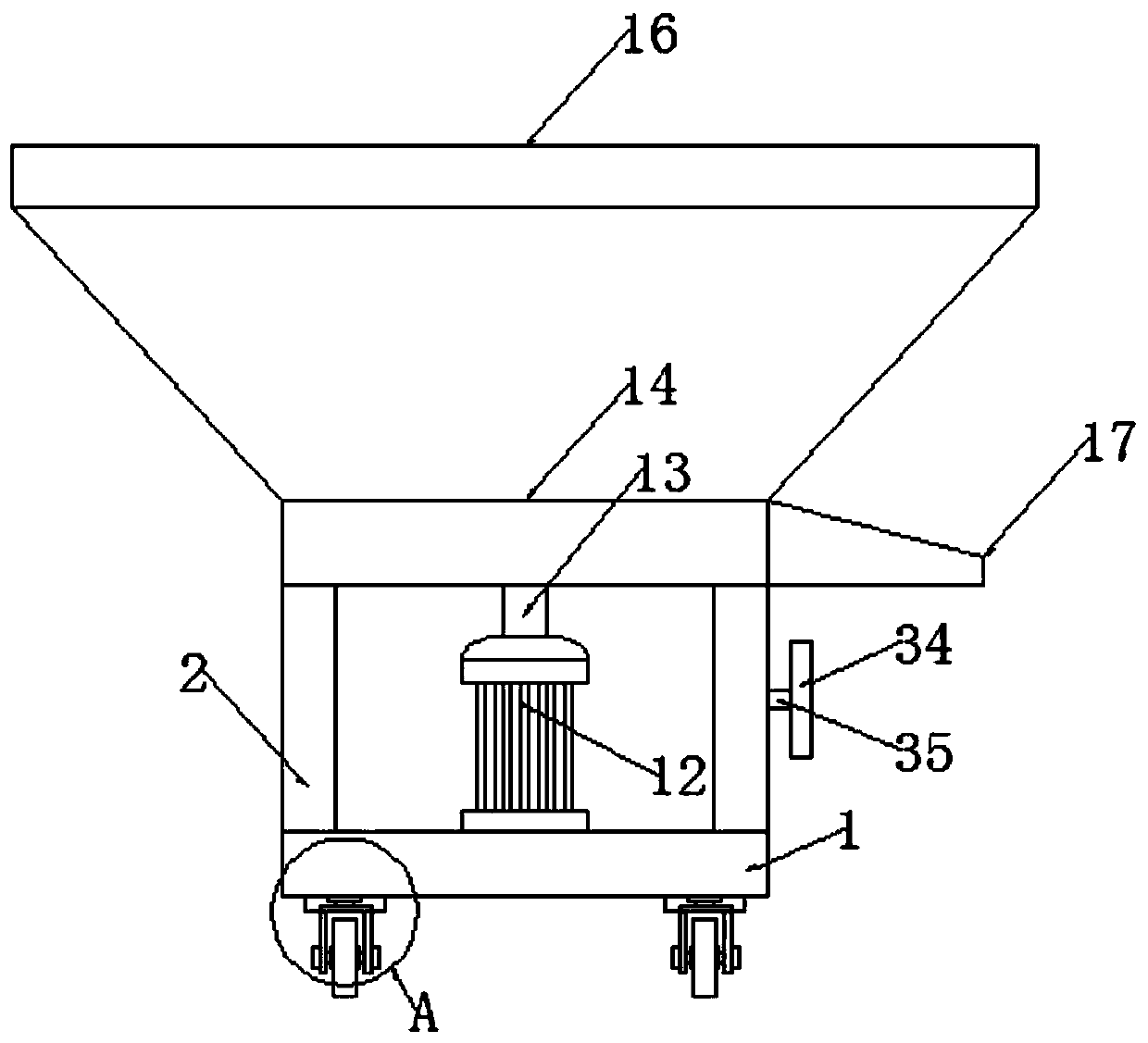

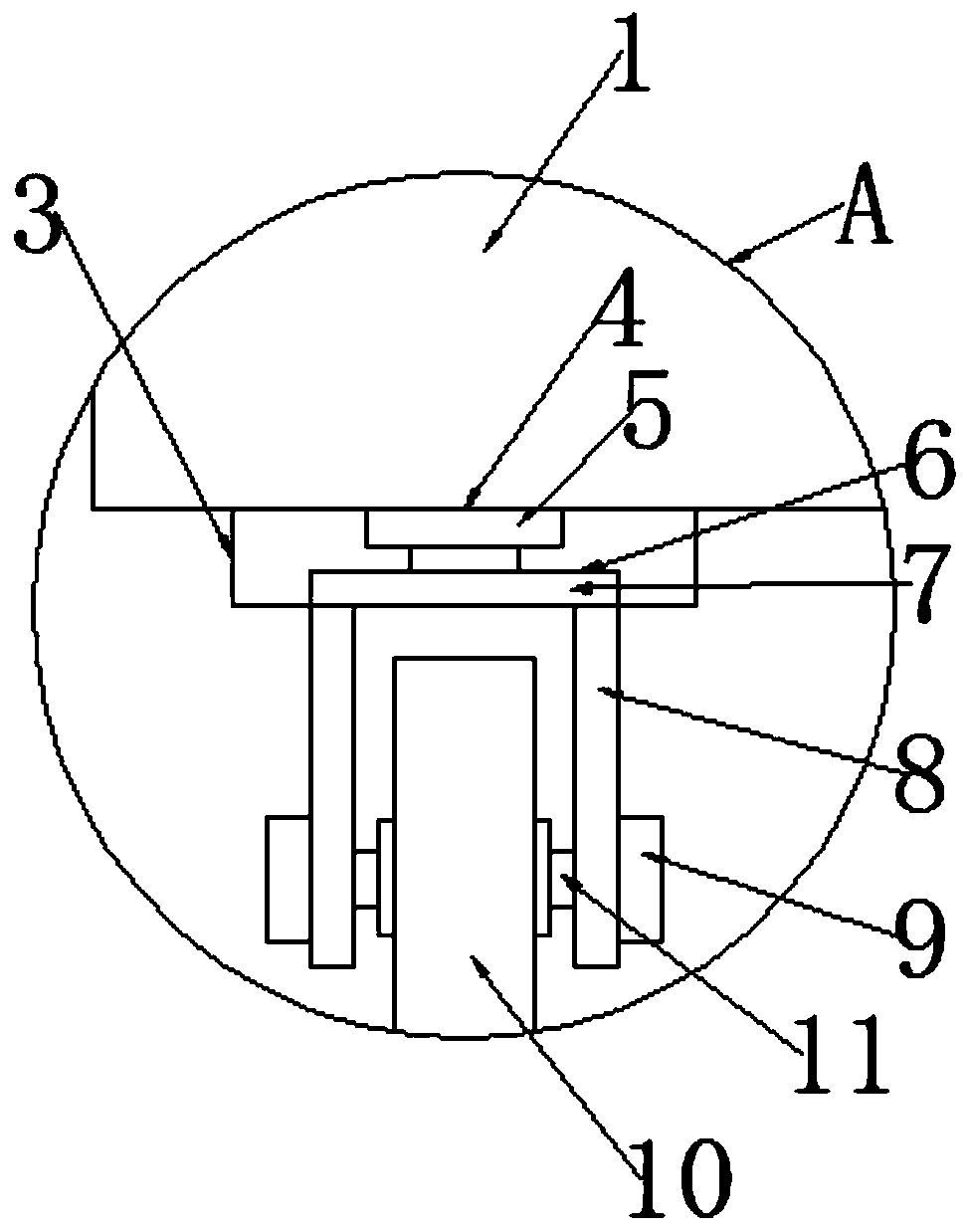

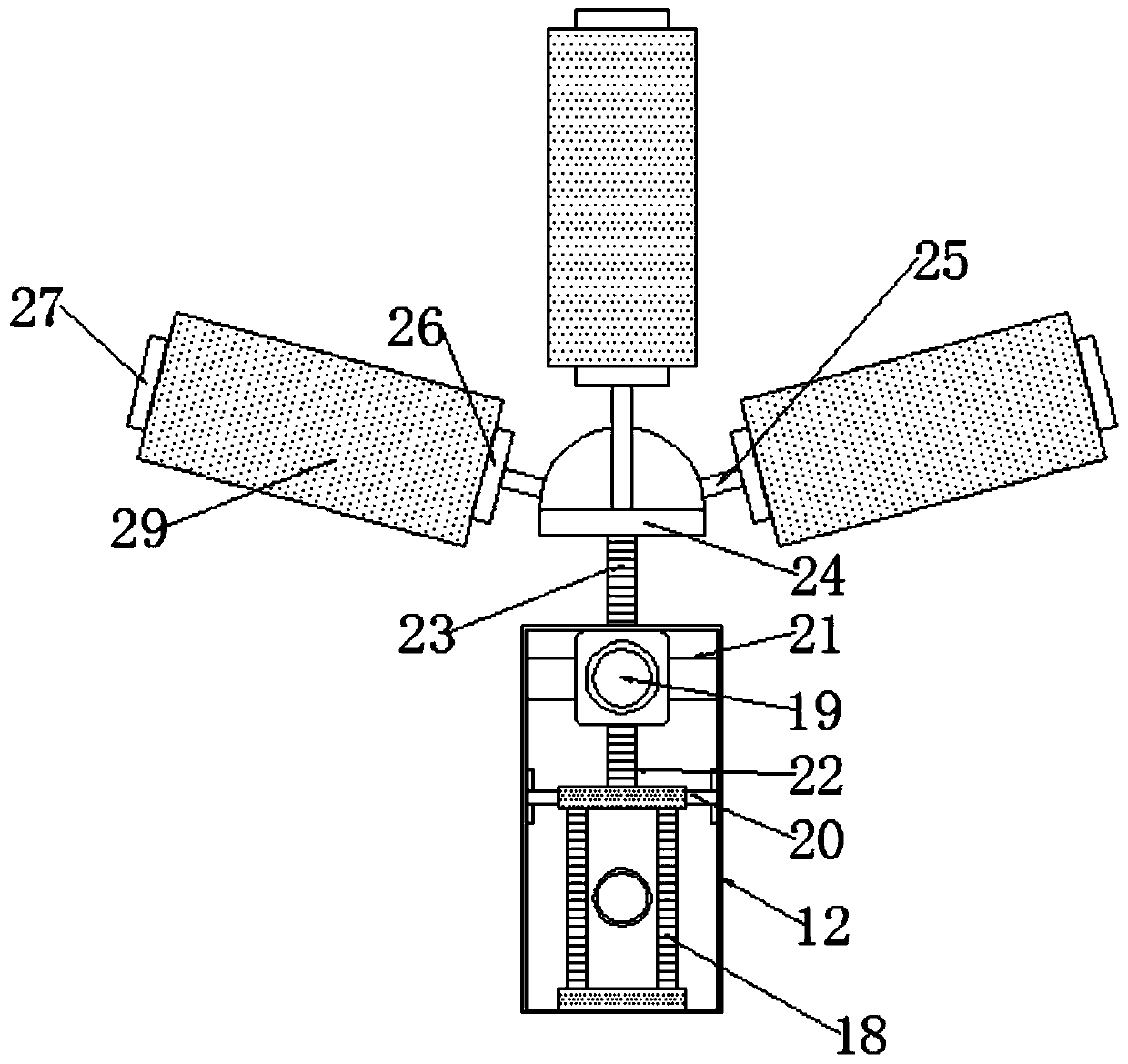

[0024] Such as Figure 1-8 As shown, this embodiment adopts the following technical solutions:

[0025] A foundry sand milling device, comprising a base plate 1, two side plates 2 are vertically and fixedly installed on the upper end surface of the base plate 1, and the two side plates 2 have the same specification and are respectively distributed on two opposite sides of the upper end surface of the base plate 1 A filter cavity 14 is fixedly installed between the two side plates 2, and a motor protection shell 12 is fixedly installed at the center of the upper end surface of the substrate 1. The central positions are fixedly connected by the drive shaft protection tube 13, the upper end surface of the filter cavity 14 is fixedly equipped with a hopper 16, and one side of the filter cavity 14 is fixedly equipped with a discharge protection plate 17, and the inside of the motor protection shell 12 It is hollow, and the motor protection shell 12 is provided with a motor 18 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com