Hinge beam ear hole repair grinding device

A hinge beam and hinge technology, which is used in grinding drive devices, grinding machines, grinding workpiece supports, etc., can solve problems such as inability to effectively ensure product accuracy and consistency, restricting the production progress of hinge beams, and high labor intensity for operators. , to achieve the effect of high grinding operation efficiency, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

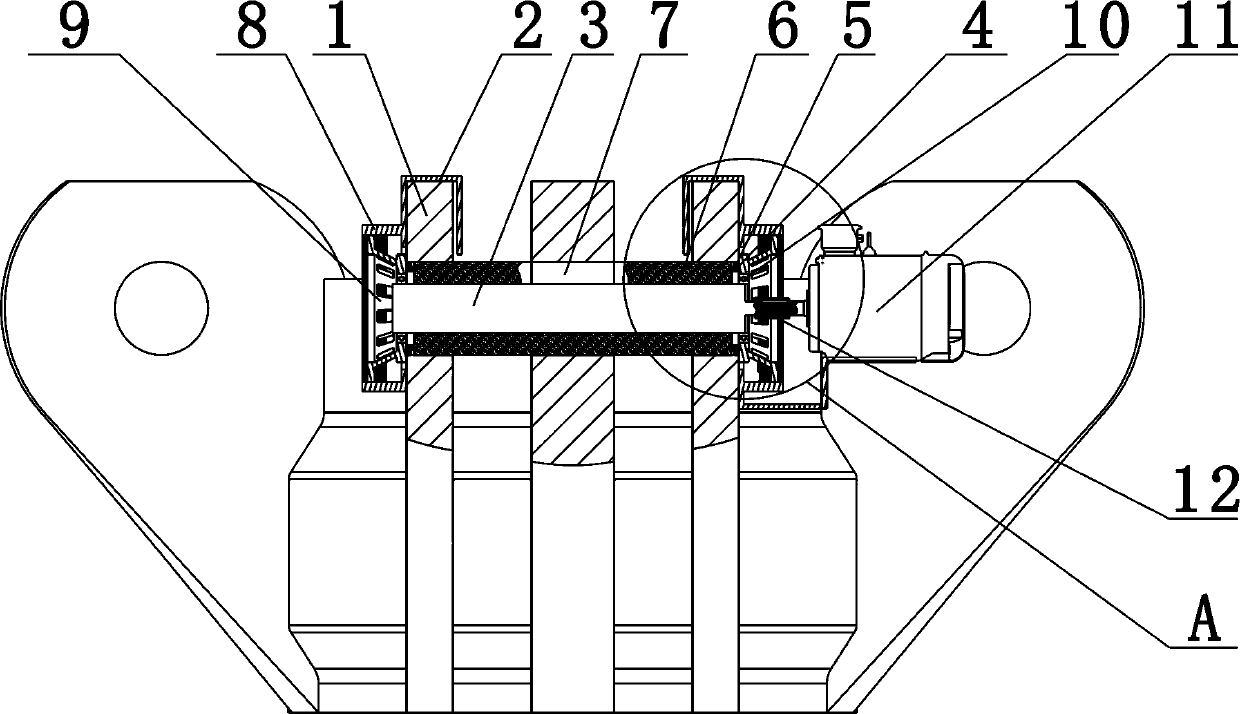

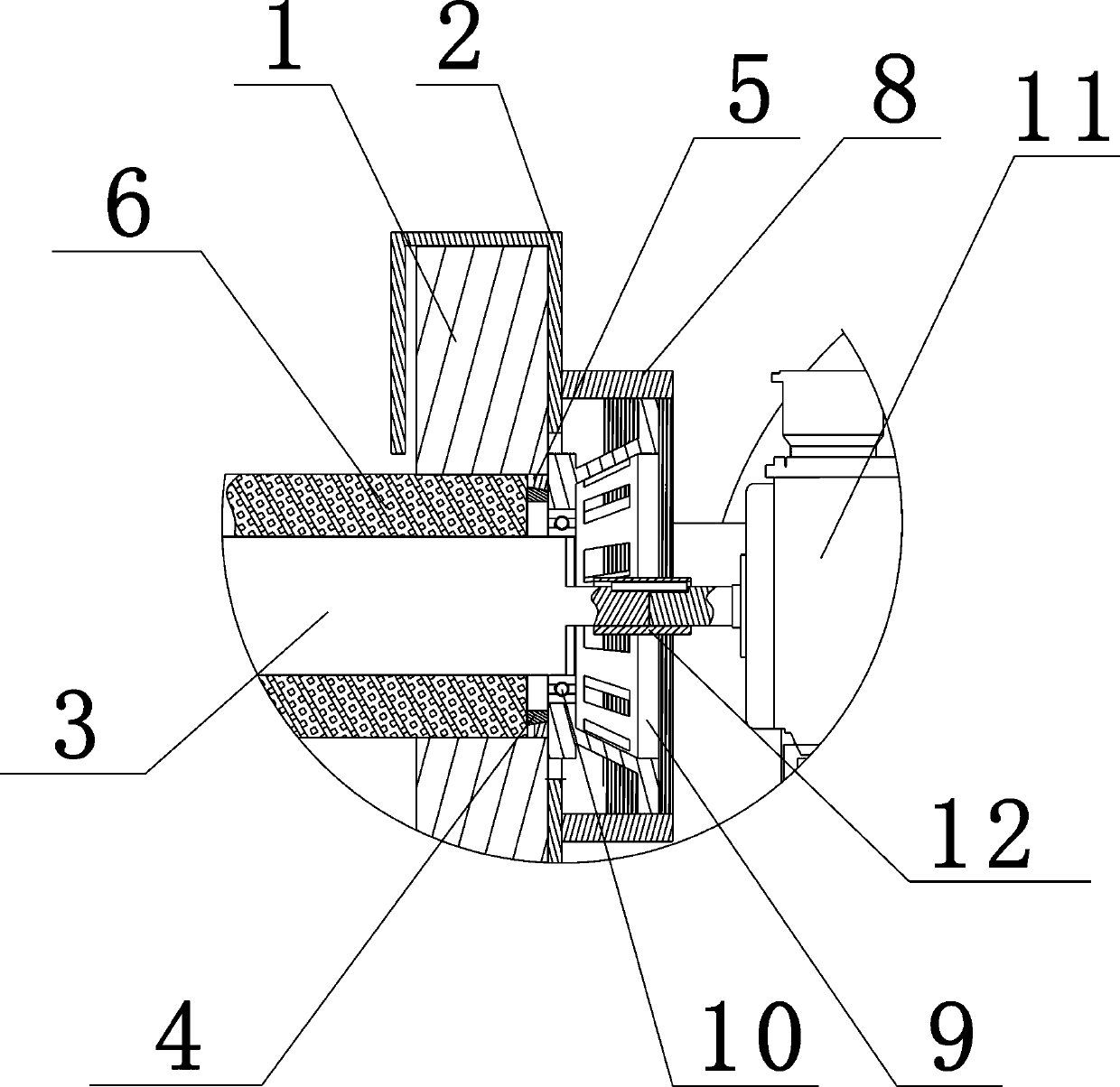

[0019] combined with Figure 1~2 , a hinged beam ear hole grinding device, including the ear piece body 1 of the hinged beam, and also includes a support frame 2, a grinding rod 3, a tapered tire expansion inner mold 4 and a tapered tire expansion tire outer mold 5; each set of ears In the ear hole 7 of the chip body 1, there is a grinding rod 3 coaxially inserted with the ear hole 7, and one end of the grinding rod 3 is provided with a motor 11 for driving the grinding rod 3; as required, the grinding rod 3 Corresponding transmission connection with the motor 11 through the coupling 12; the outer wall of the grinding rod 3 near both ends is movably provided with a conical tire-inflating inner mold 4, and the grinding rod 3 is located between the two coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com