High-efficiency mill

A fine crushing and high-efficiency technology, applied in the field of material crushing and grinding, can solve the problems of high cost, large one-time investment and high energy consumption, and achieve the effect of low processing cost, low equipment investment and high grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Its structure will be further described with reference to the embodiments given in the accompanying drawings:

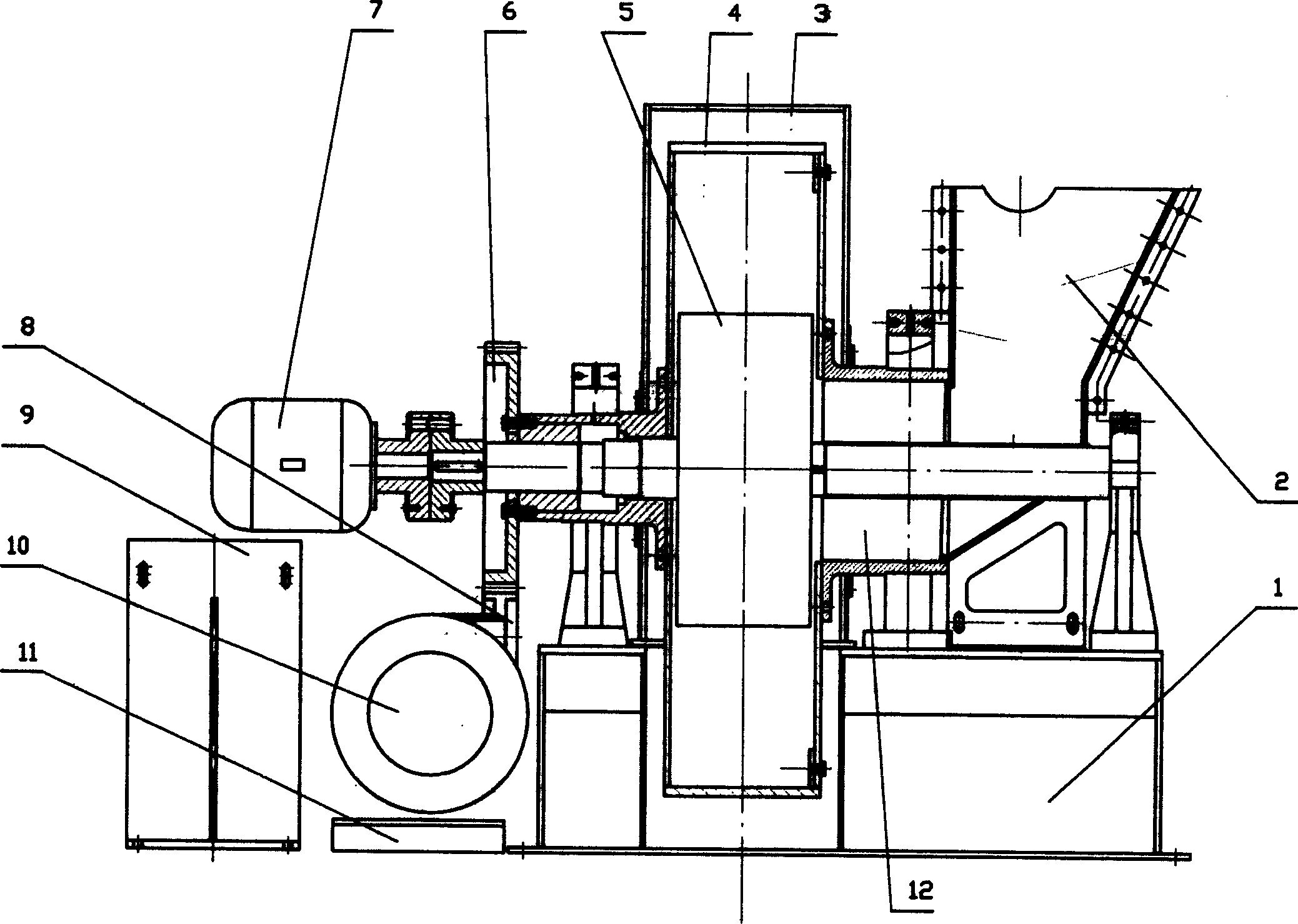

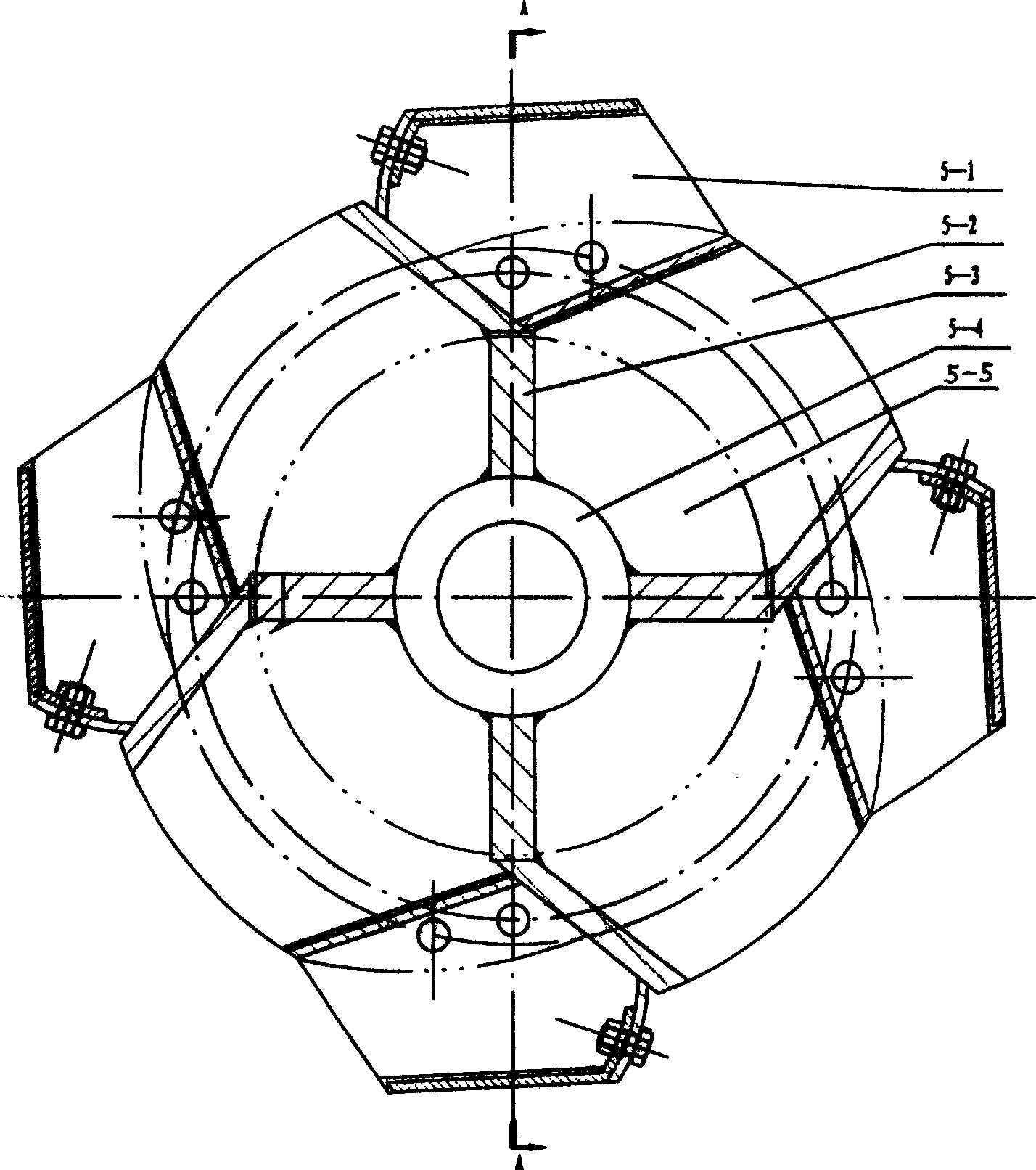

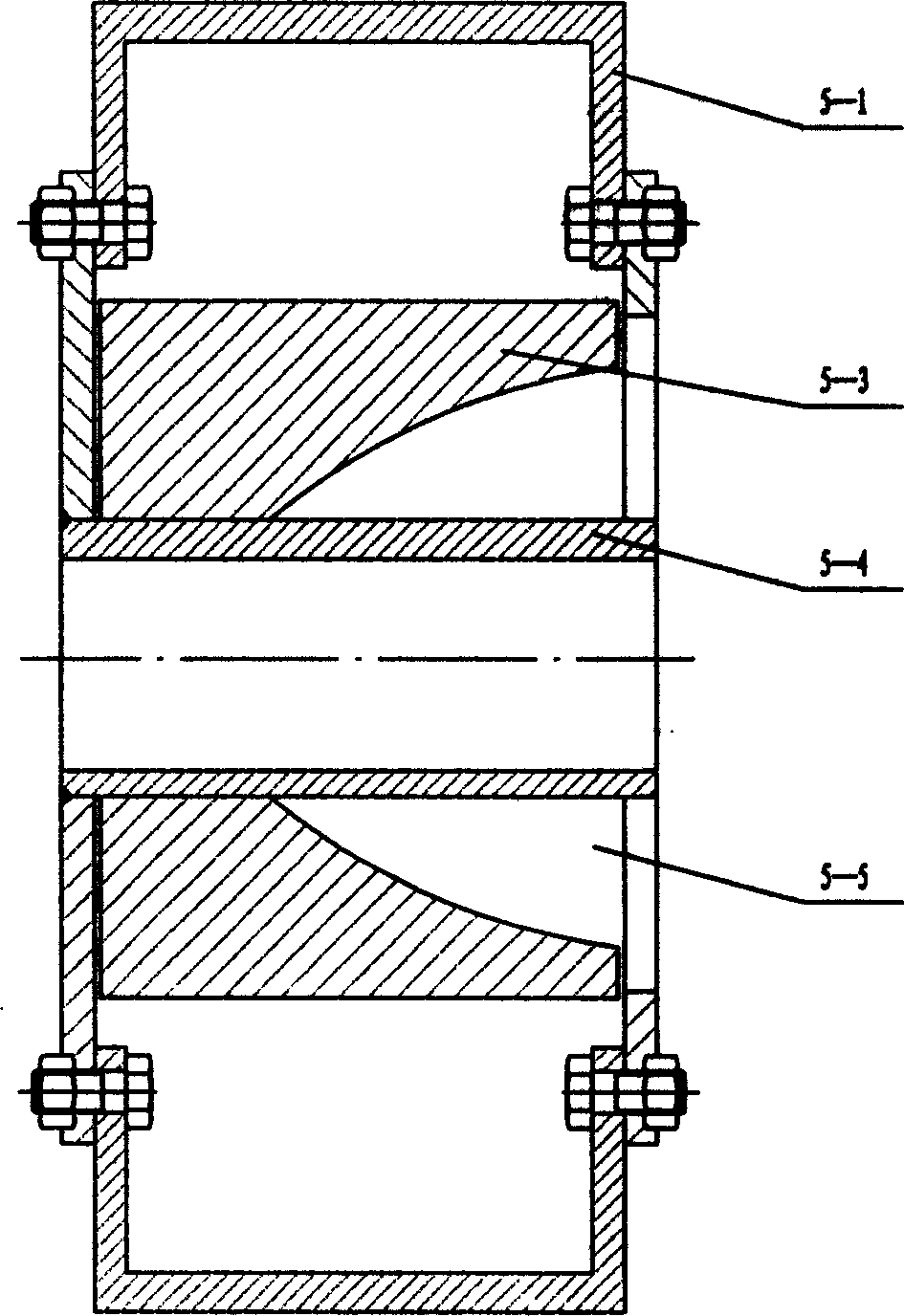

[0014] as attached figure 1 As shown, the upper part of the machine base 1 of the present invention is provided with a feeding hopper 2, the output shaft of the motor 7 is connected to the rotor shaft through a coupling, and the other end of the rotor shaft is horizontally arranged and supported on the machine base. The rotor 5 fixed on the rotor shaft rotates with the rotor shaft at a high speed. The motor 10 drives the drum 4 to rotate through the gear reduction mechanism, namely the pinion 8 and the large gear 6. The drum 4 is arranged around the rotor 5, that is, the rotor 5 is located in the drum 4. The drum 4 is concentric with the rotor 5 and rotates in the opposite direction. A working chamber is formed between the rotor 5 and the drum 4 . The motor 7 is supported by the main motor support 9, the small motor 10 is supported by the small motor support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com