Spray pump assembling machine

A technology for assembly machines and spray pumps, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive manual input, low degree of automation of the production line, and low efficiency, so as to ensure hygiene and safety, reduce manual input, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below with reference to the accompanying drawings.

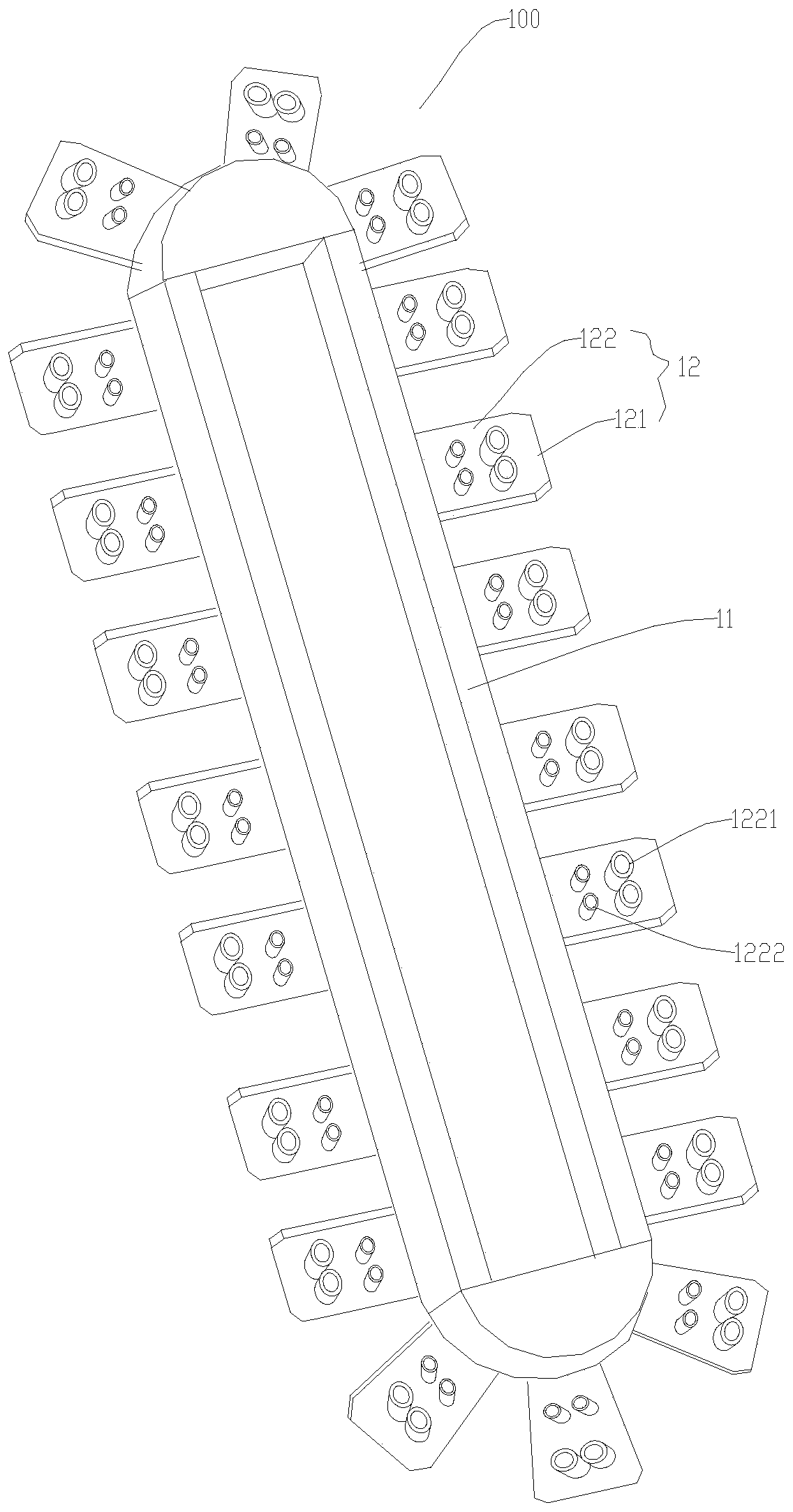

[0026] see Figure 1 to Figure 9 , in this embodiment, the spray pump assembly machine adopts a rotary assembly process, and finally completes the assembly of the spray bottle cap according to the preset assembly sequence.

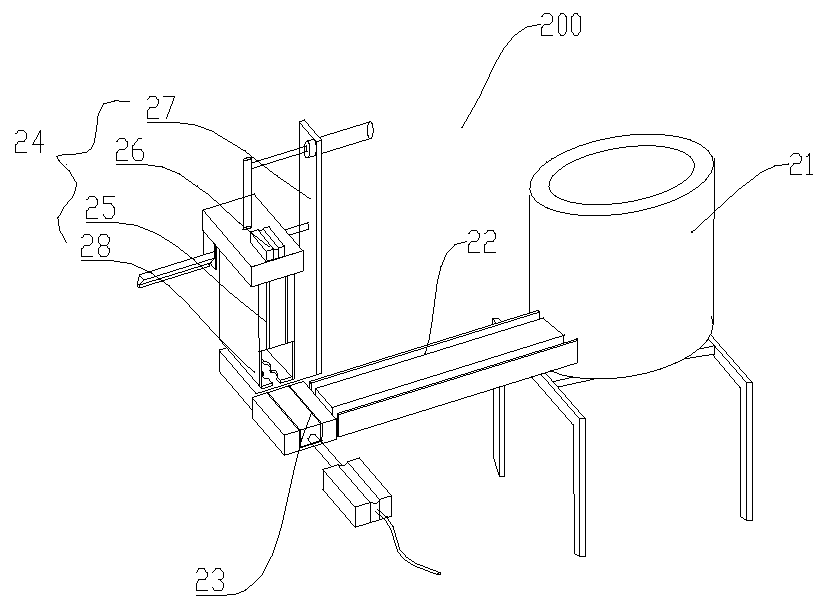

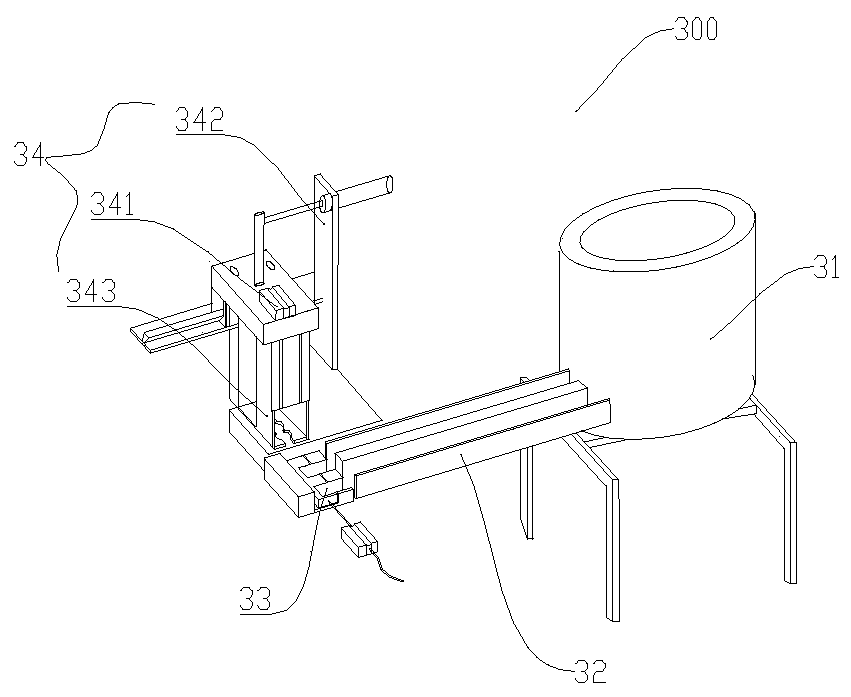

[0027] Specifically, the spray pump assembly machine includes: a rotary station assembly 100, a pump core feeding assembly 200, a screw cap feeding assembly assembly 300, and a nozzle feeding assembly sequentially distributed on the outer edge of the rotating station assembly 100. assembly 400, dust cover feeding assembly assembly 500, overturning assembly 600, gasket feeding assembly 700, suction pipe insertion assembly 800, and PLC (not shown); wherein, under the control of the PLC, the The pump core feeding assembly 200, the screw cover feeding assembly assembly 30, the nozzle feeding assembly assembly 400, the dust cover feeding assembly assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com