Cam type high-frequency multi-color automatic scribing device

An automatic scribing and cam-type technology, applied in the field of machinery, can solve the problems that the device cannot withstand the impact force, beating, single line color, etc., and achieve the effect of stable and reliable scribing, good conveying, and solving external splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

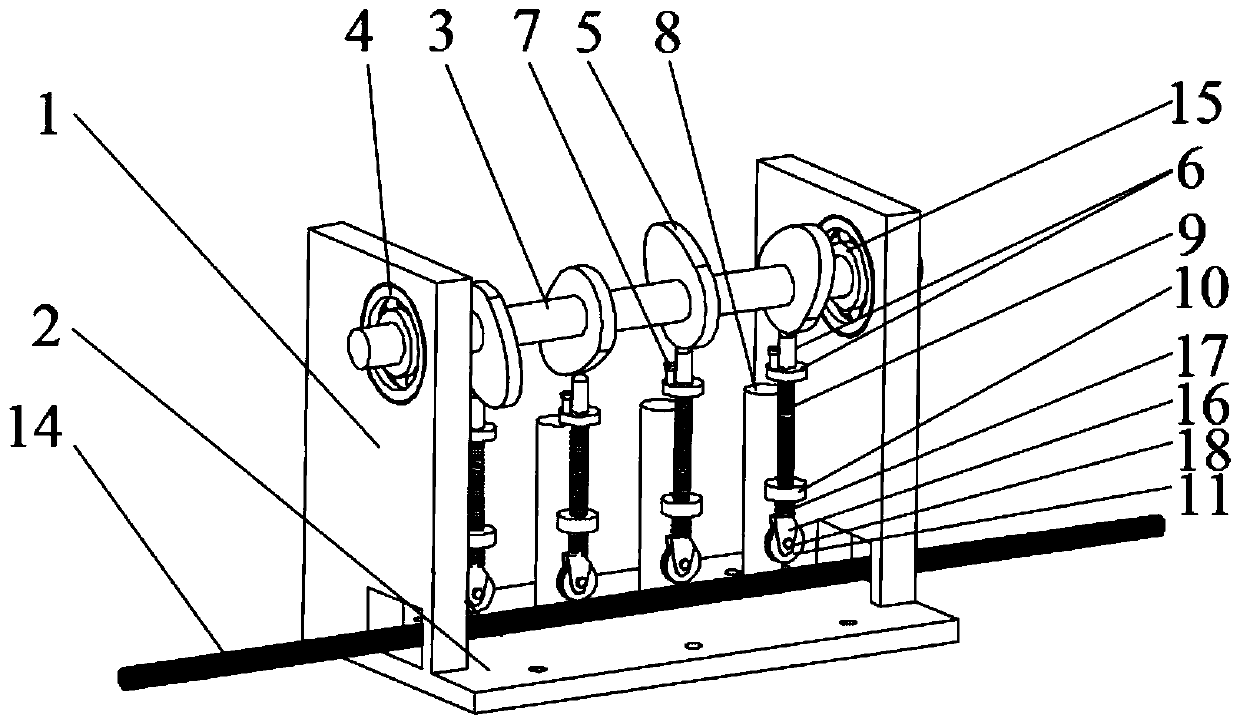

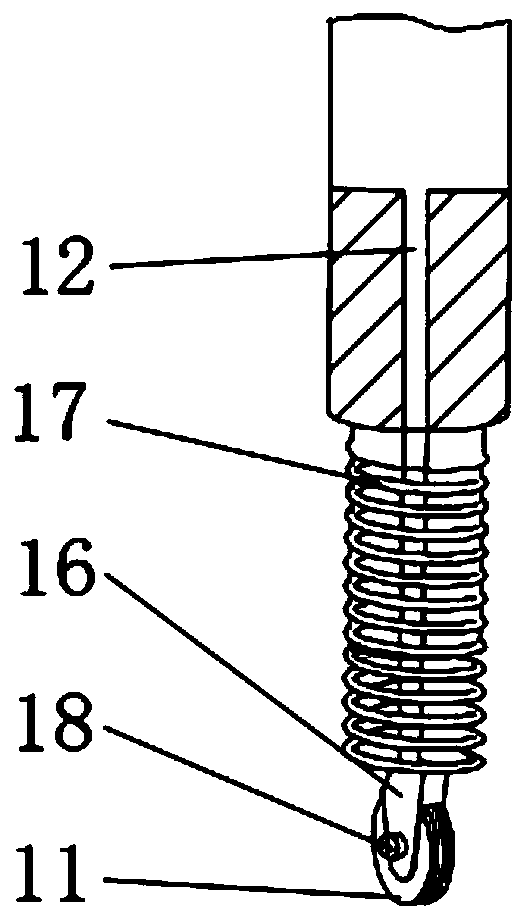

[0019] Such as Figure 1-2 As shown, a cam-type high-frequency multi-color automatic scribing device includes a bracket, a cam push rod mechanism and an ink supply mechanism. The bracket includes a vertical plate 1 and a bottom plate 2, and two vertical plates 1 are vertically arranged on the The two ends of the bottom plate 2, four cylindrical bosses 8 are uniformly arranged on the bottom plate 2; the cam push rod mechanism includes a drive shaft 3, a cam 5, a high-strength spring 9, a push rod 6 with an upper support and a lower push rod mechanism. Support 10, the two ends of the driving shaft 3 are installed on two vertical plates 1 through bearings 4, and four cams 5 are fixedly installed on the driving shaft 3, and the cams are sequentially arranged along the circumference of the driving shaft 3 Evenly distributed at intervals of 90°, the upper end of the push rod 6 is provided with the upper holder, the lower holder 10 is fixedly installed on the cylindrical boss 8, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com