An auxiliary conveying device for a double-layer cloth rear beam roller of a textile machine

A technology for textile machinery and conveying devices, which is applied in the field of auxiliary conveying devices for double-layer cloth rear beam rollers of textile machinery, and can solve the problems of affecting the appearance of the cloth, difficulty in breaking free, and the influence of the cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

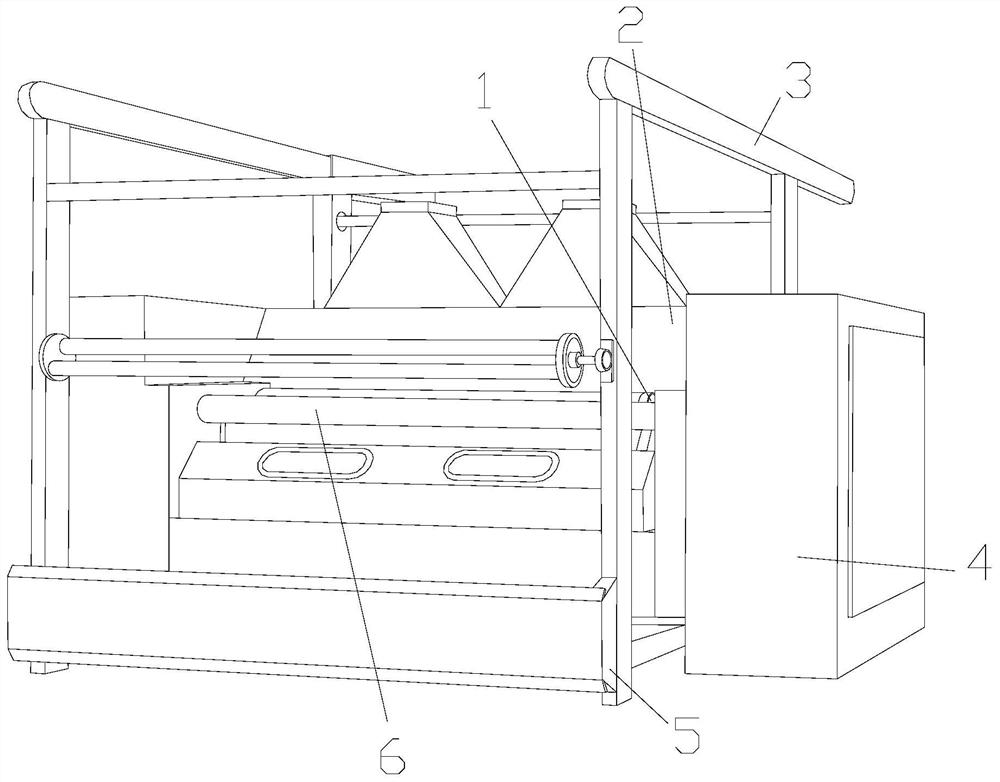

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides an auxiliary conveying device for a double-layer cloth rear beam roller of a textile machine.

[0034] The rear beam roller device 1 is arranged under the deworming rotary cylinder 2, the deworming rotary cylinder 2 is welded to the outer surface of the operation box 4, the support frame 3 and the bottom support seat 5 are an integrated structure, and the front beam roller 6 is welded with the outer surface of the operation box 4.

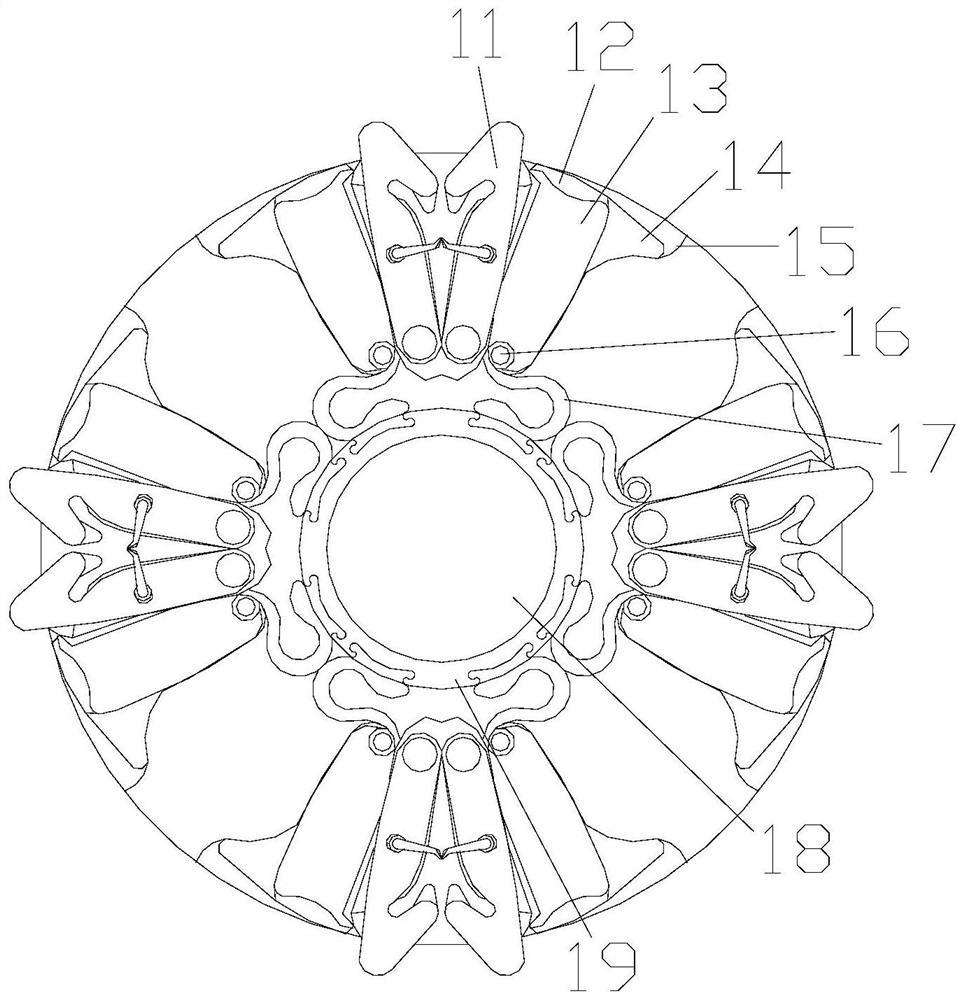

[0035] The back beam roller device 1 includes a drip fitting extension rod 11, a sponge body 12, a backup extension rod 13, an extension support plate 14, a movable fixing groove 15, an elastic push column 16, an elastic return plate 17, a central spindle 18, and a reinforcement card. The buckle layer 19, the drip fitting extension rod 11 is located between the sponge bodies 12, the sponge body 12 is installed on the outer surface of the extension rod 13, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com