A flue gas denitrification device and a flue gas denitrification method

A technology for flue gas and denitrification, which is applied in separation methods, chemical instruments and methods, and gas treatment, etc., can solve the problem that denitration methods are difficult to achieve industrialization, and achieve the effect of reducing airflow resistance and ensuring contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

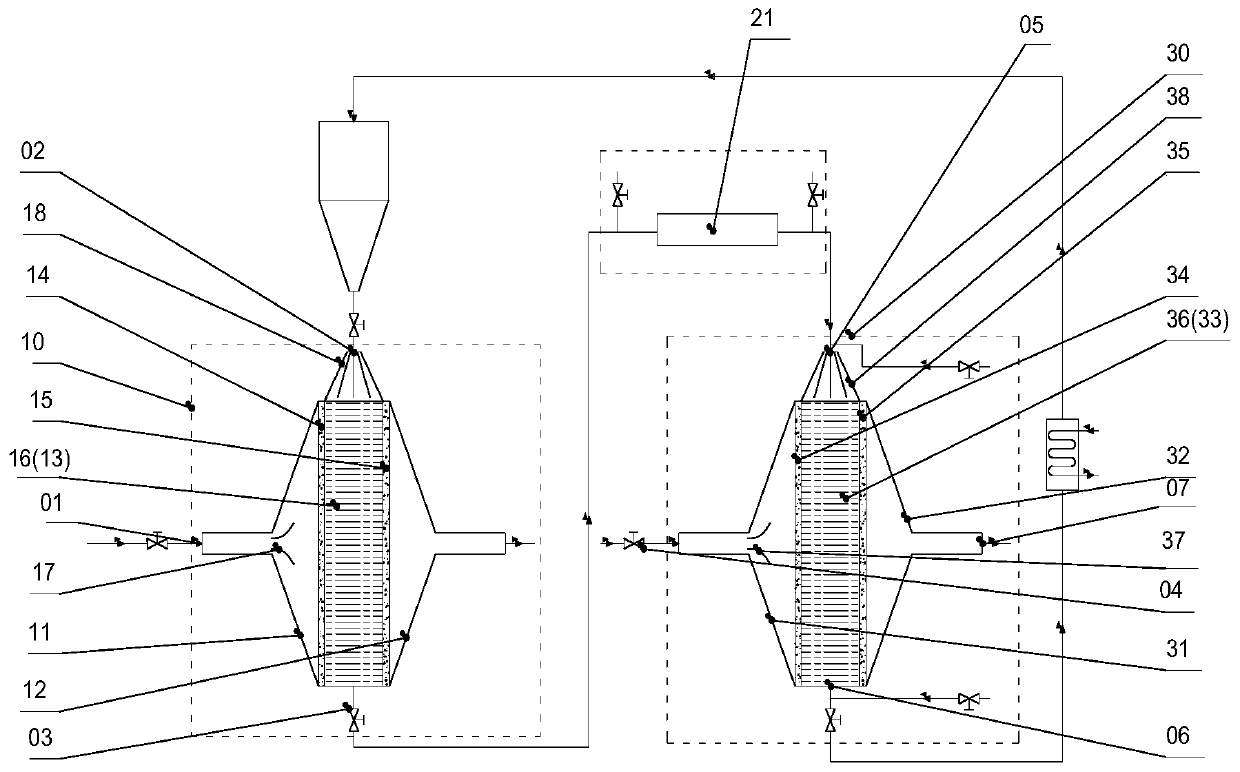

[0048] use figure 1 The shown flue gas denitrification device performs adsorption and reduction treatment on flue gas containing nitrogen oxides in order to achieve denitrification, and uses a chain furnace with a capacity of 0.7 steam tons / hour to generate the flue gas required for treatment.

[0049]The main components of flue gas containing nitrogen oxides are shown in Table 1.

[0050] Table 1

[0051] Element CO NO x

O 2

CO 2

content 0.084wt% 50ppm 16.83wt% 1.99wt%

[0052] Wherein, the catalyst is granular activated carbon with a particle size of 500 μm to 4 mm, and the moving speed of the catalyst in the flue gas adsorption chamber and the moving speed of the catalyst in the flue gas reduction chamber are each independently 0.03 m / s.

[0053] In the flue gas adsorption chamber, the temperature at which the catalyst adsorbs the flue gas is 250°C, the thickness of the catalyst along the flue gas flow direction is 1.5m, and th...

Embodiment 2

[0058] The catalyst is granular activated carbon with a particle diameter of 2 mm to 10 mm, and the rest are the same as in Example 1. Use online flue gas analyzer to detect flue gas import and export NO in real time x concentration, the denitrification rate of flue gas after reduction is 74%.

Embodiment 3

[0060] The moving speed of the catalyst in the flue gas adsorption chamber and the moving speed of the catalyst in the flue gas reduction chamber are each independently 0.6 m / s. Others are with embodiment 1.

[0061] The online flue gas analyzer is used to detect the NOx concentration at the inlet and outlet of the flue gas in real time, and the denitrification rate of the flue gas after reduction is 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com