A kind of ceramic bottom grinding machine and using method thereof

A bottom grinding machine and ceramic technology, which is applied in the direction of grinding frame, grinding machine parts, grinding machines, etc., can solve the problems of difficult ceramic fixing, and achieve the effect of easy adsorption, avoiding displacement, and simple fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

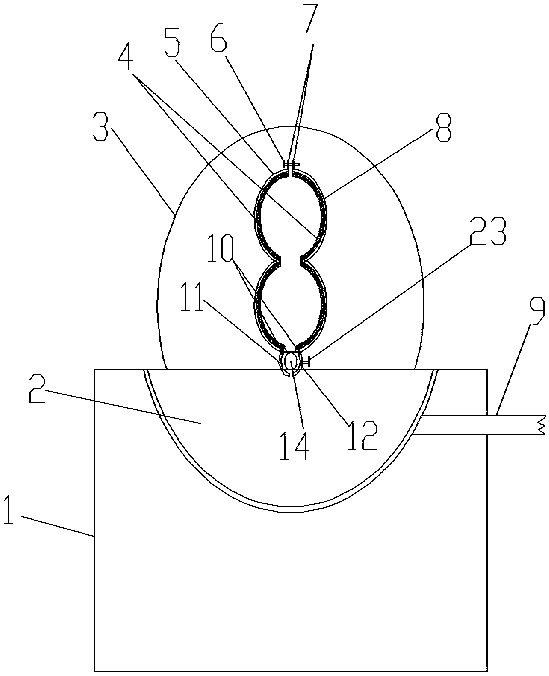

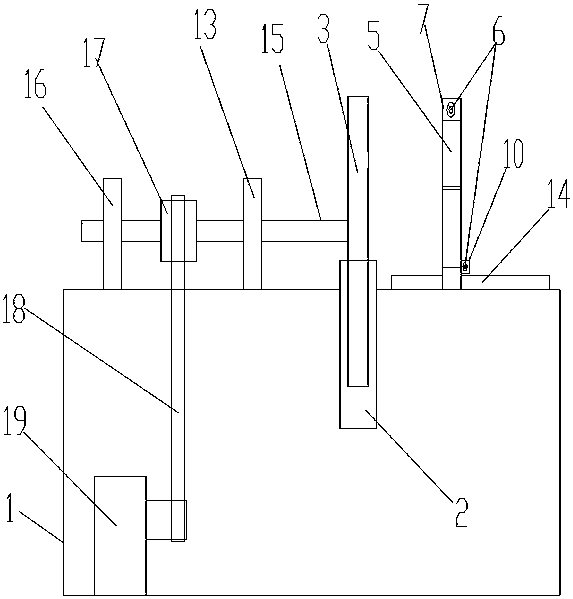

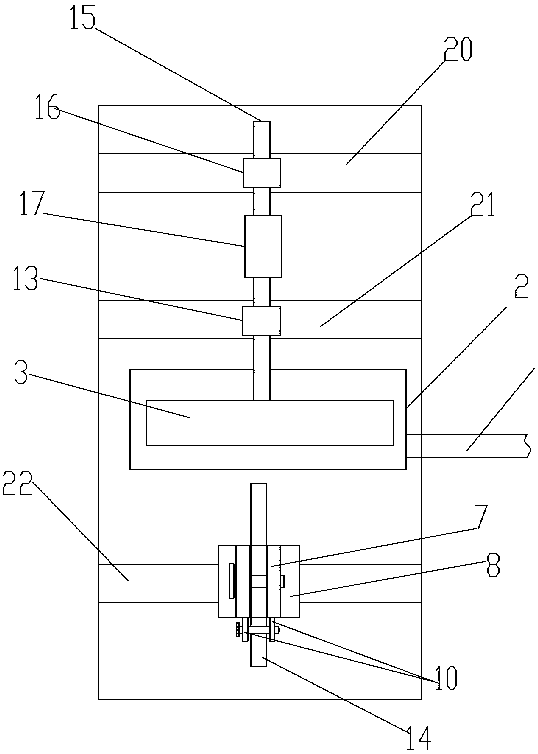

[0020] Such as figure 1 , 2 A kind of ceramic bottom grinding machine shown in , 3, comprises frame 1, transmission shaft 15, dust suction cover 2, slide bar 14, is provided with grinding disc 3 on the frame 1, and grinding disc 3 diameters 500-700mm, can adopt Grinding wheel etc. can play the roulette form of grinding effect, and grinding disc 3 rear side middle parts are fixed with transmission shaft 15, and grinding disc 3 bottoms are matched with dust collection cover 2, and dust collection cover 2 is arc shape, and dust collection cover 2 and suction Dust machine inlet 9 is connected. The dust collection cover 2 can wrap the lower part of the grinding disc 3 very well, and the lower part of the grinding disc 3 moves in the dust collection cover 2, and the grinding dust ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com