Grooving width adjustable road grooving machine

A technology with adjustable groove width, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of cumbersome operation of slotting blades and inconvenience for construction personnel, and achieve the effect of simple operation and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

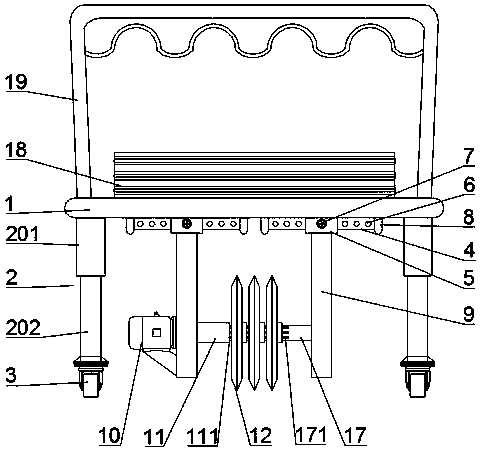

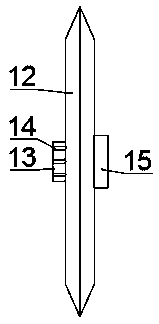

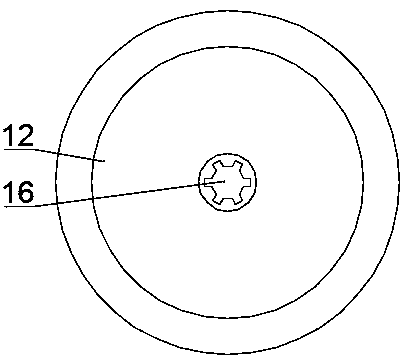

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] A road surface grooving machine with adjustable grooving width, comprising a mounting table 1, an elastic telescopic mechanism 2 connected to the lower part of the mounting table 1, casters 3 installed on the lower part of the elastic telescopic mechanism 2, and a slotting blade 12 , when it is necessary to select the grooving width at the crack of the road surface, the grooving blade 12 needs to be replaced, so the replacement of the grooving blade 12 is not only cumbersome to operate, but also needs to carry all the grooving blades 12 of each specification, Inconvenience to construction workers.

[0020] It is particularly important in the present invention that, as Figure 1-3 As shown, the mounting table 1 is connected with a pair of traversing limiting mechanisms, and the movable end of the traversing limiting mechanism is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com