Steel plate composite shear wall of built-in cross-pulling screws and construction method of steel plate composite shear wall

A combined shear wall and pair-pulling screw technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of cumbersome construction procedures, insufficient lateral rigidity of concrete pouring, and difficulty in ensuring the smoothness of the wall surface, so as to achieve enhanced connection performance, The effect of ensuring flatness and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

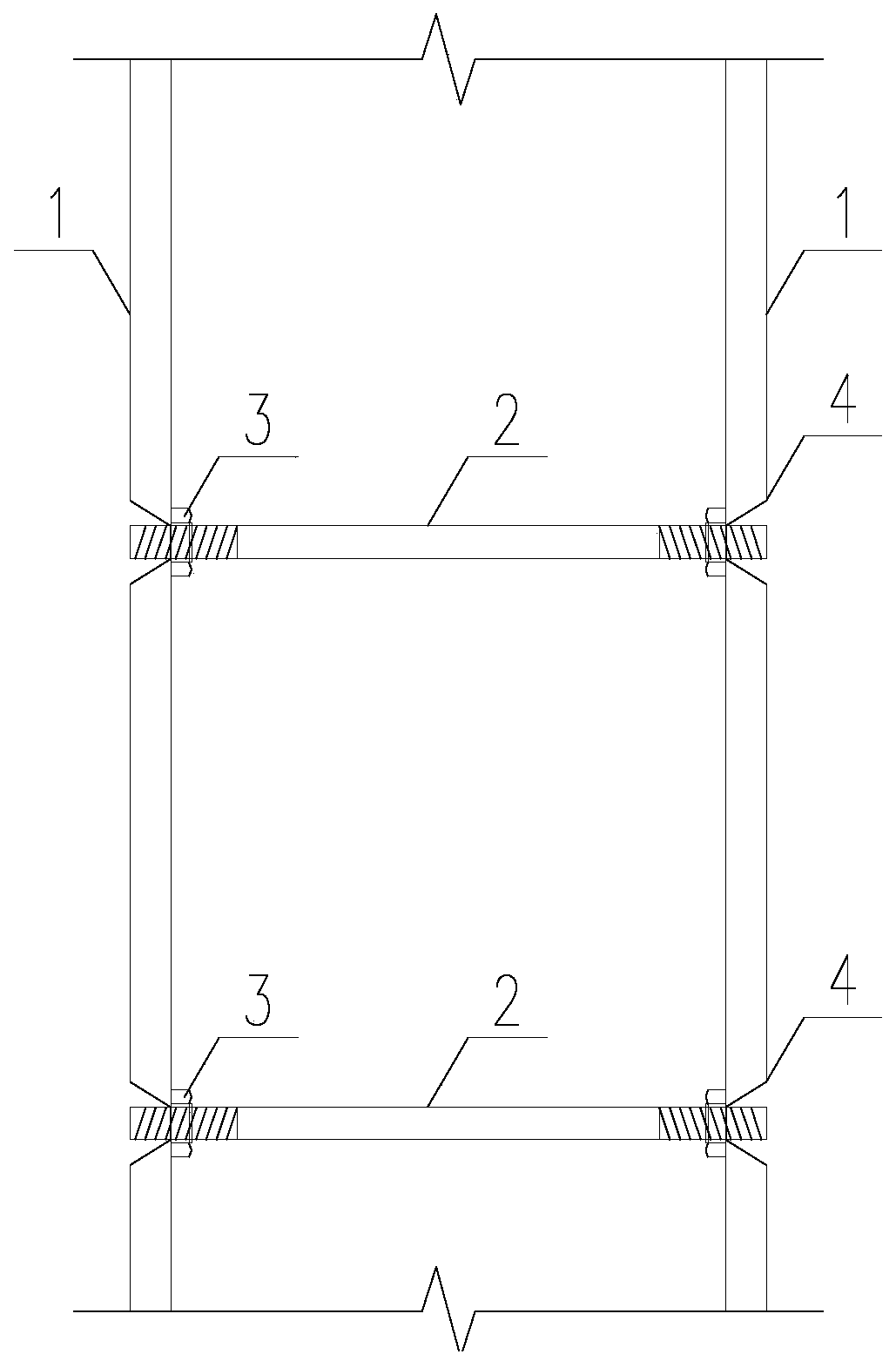

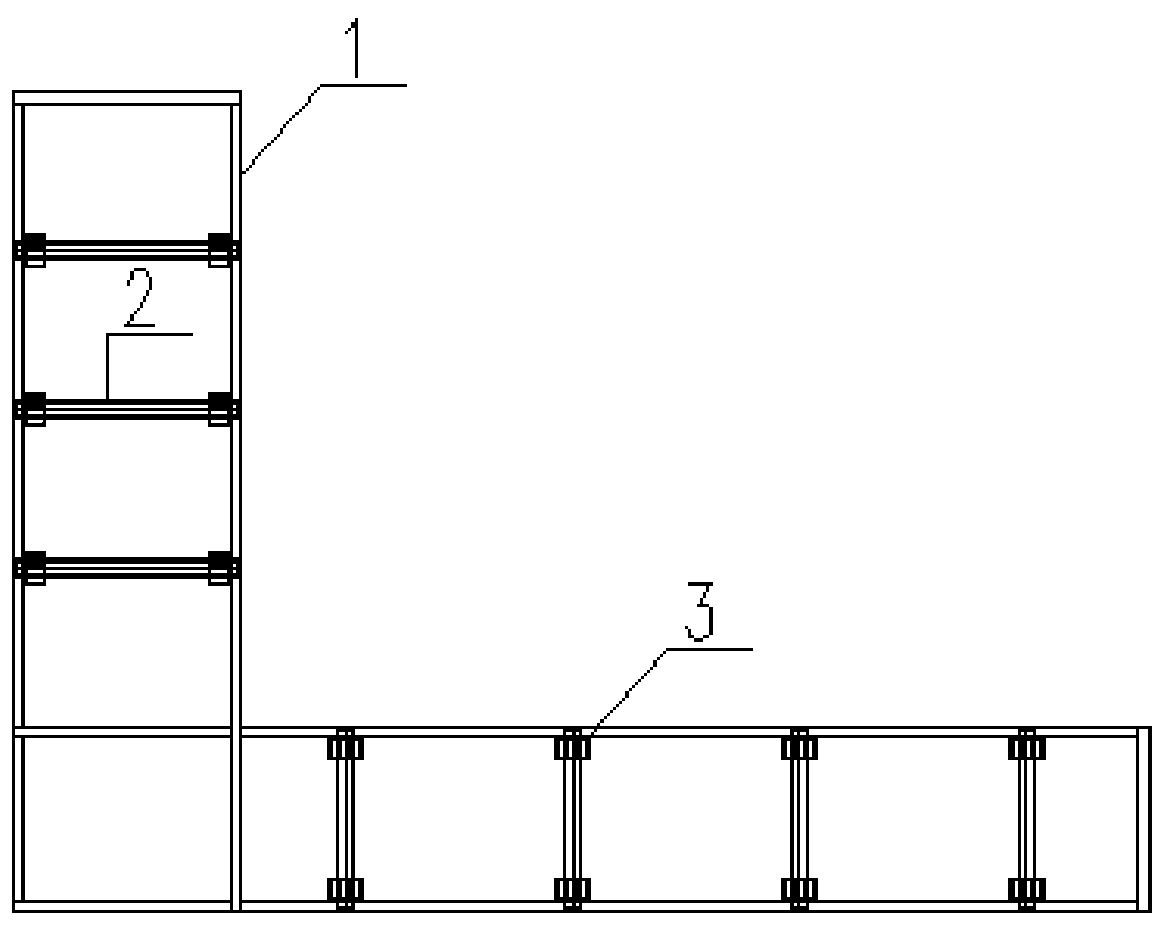

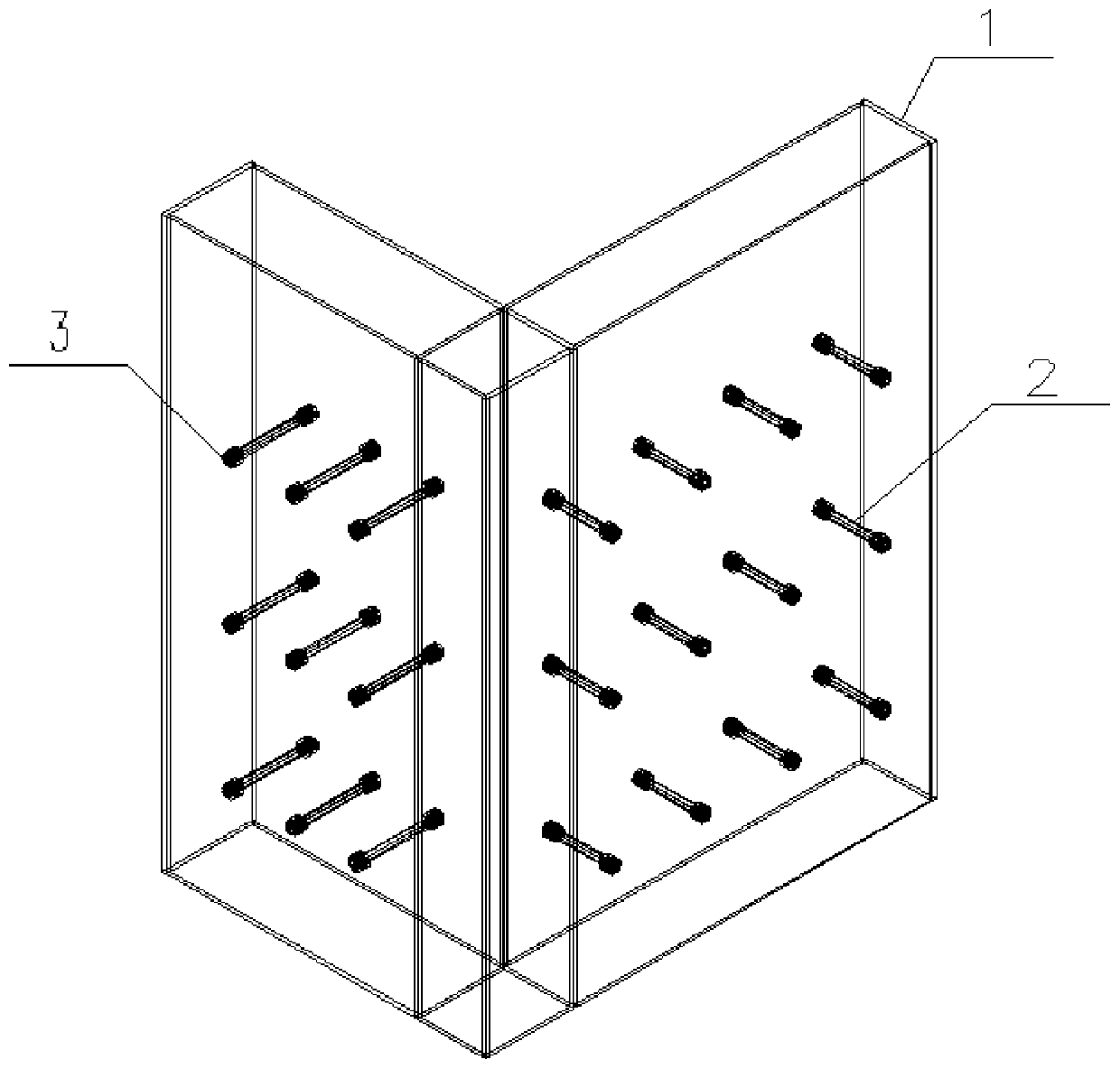

[0026] Such as Figure 1~3 The steel plate composite shear wall with built-in tension screw includes two corresponding steel plate composite shear wall steel plates 1, tension screw 2, limit nut 3 and plug welding hole 4, and the composite shear wall steel plate 1 is A number of corresponding plug welding holes 4 are evenly opened, and the positions of the plug welding holes 4 on the combined shear wall steel plate 1 correspond one by one, and the plug welding holes 4 are pierced with a pull screw 2 for constraining the combined shear wall steel plate 1 During the processing of the combined shear wall steel plate 1 in the factory, the pull screw 2 is built into the two combined shear wall steel plates 1, and a pair of pull screws 2 on the inner side of the combined shear wall steel plate 1 are set for fixing. The limit nut 3 of the pulling screw 2 is used to adjust the thickness and verticality of the steel plate composite shear wall during the processing through the limit nut...

Embodiment 2

[0028] The difference between embodiment 2 and embodiment 1 is that the plug welding hole 4 is in an inverted cone shape, and the outer diameter of the plug welding hole 4 is larger than the inner diameter of the plug welding hole 4 .

[0029] A construction method of a steel plate composite shear wall with built-in tension screws, comprising the following steps:

[0030] A. Put the combined shear wall steel plate 1 on one side of the steel plate combined shear wall flatly on the ground, screw two limit nuts 3 on the pull screw 2, and then place all the pull screws 2 of the steel plate wall in alignment On the combined steel plate shear wall steel plate 1 on the ground, spot-weld the limit nut 3 and the combined shear wall steel plate 1 on the ground after alignment adjustment;

[0031] B. Adjust the position of the limit nut 3 at the other end of the pull screw 2 according to the thickness and verticality of the steel plate combined shear wall, and connect the plug welding ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com