Support-truss structure supporting coal hopper

A truss structure and coal hopper technology, applied in industrial buildings, building types, buildings, etc., can solve the problems of increasing the cost of the main factory building, unfavorable earthquake resistance, and high price of high-strength steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

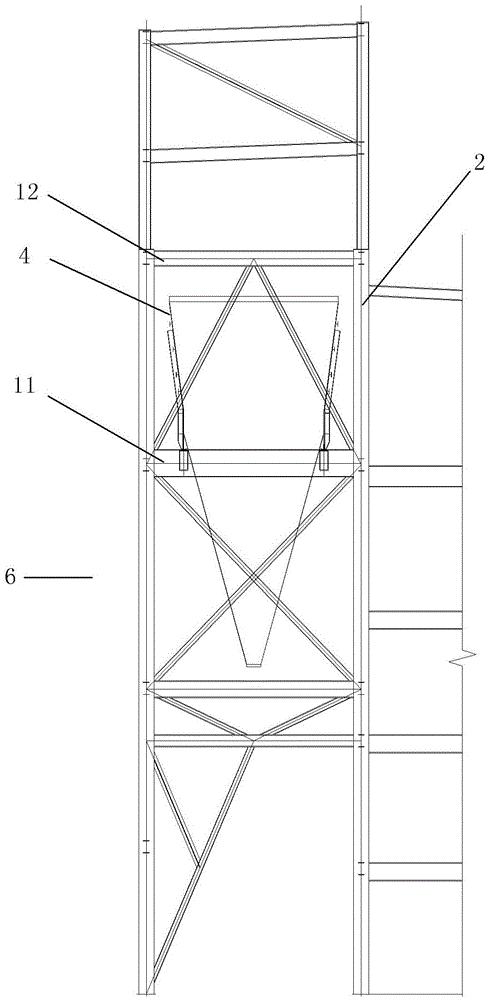

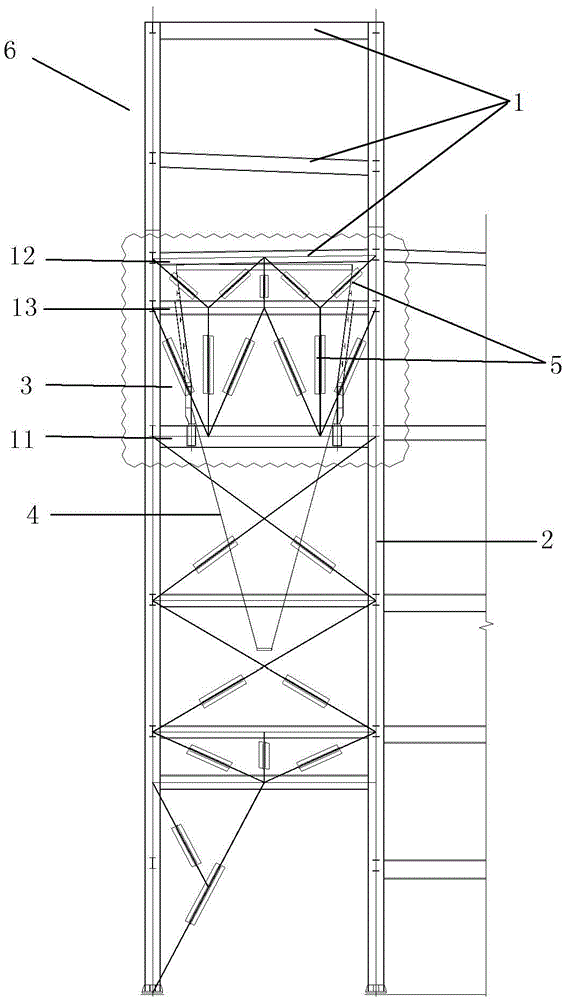

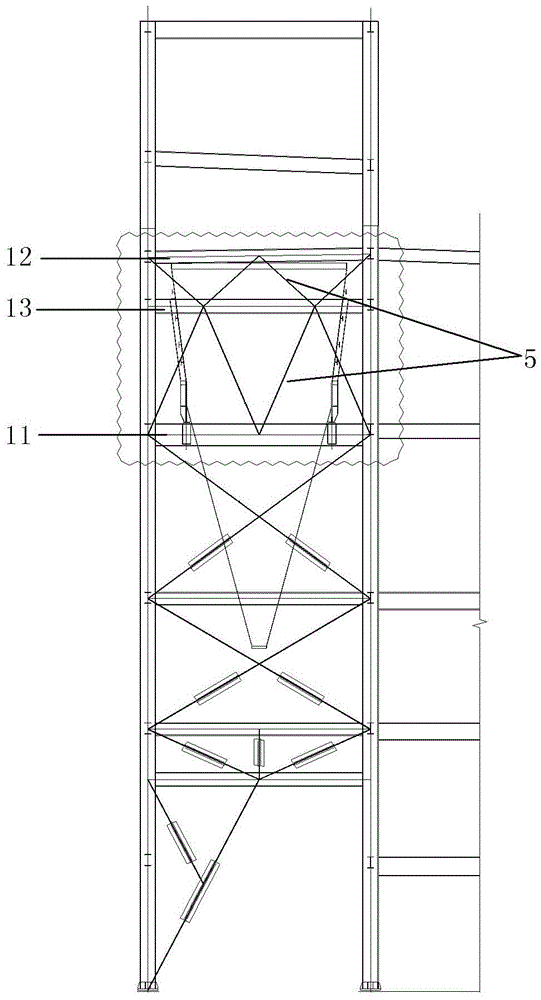

[0046] The support-truss structure supporting the coal scuttle of the present invention is arranged in the coal bunker room 6 of the power plant, and includes: a frame beam 1 , a frame column 2 and a truss structure 3 . Wherein, the frame beam 1 includes a coal bucket support beam 11 , a belt layer support beam 12 and an intermediate beam 13 , and the intermediate beam 13 is located between the coal bucket support beam 11 and the belt layer support beam 12 . The frame beam 1 and the frame column 2 are perpendicular to each other, and the truss structure 3 is arranged in the frame structure plane defined by the mutually parallel coal hopper support beam 11 and belt layer support beam 12 and the frame column 2 . The coal hopper 4 is supported on the coal hopper support beam 11 .

[0047] The support-truss structure of the present invention can be a double-layer truss structure, such as Figure 2-3 As shown, the support-truss structure includes an intermediate beam 13, and the tru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com