Rear tilt angle pumping unit

A technology of pumping unit and driving mechanism, which is applied in the direction of mining fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as unreasonable structure, difficult long stroke, complicated principle, etc., and achieve simple structure and reduce steel The effect of simple dosage and operation principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

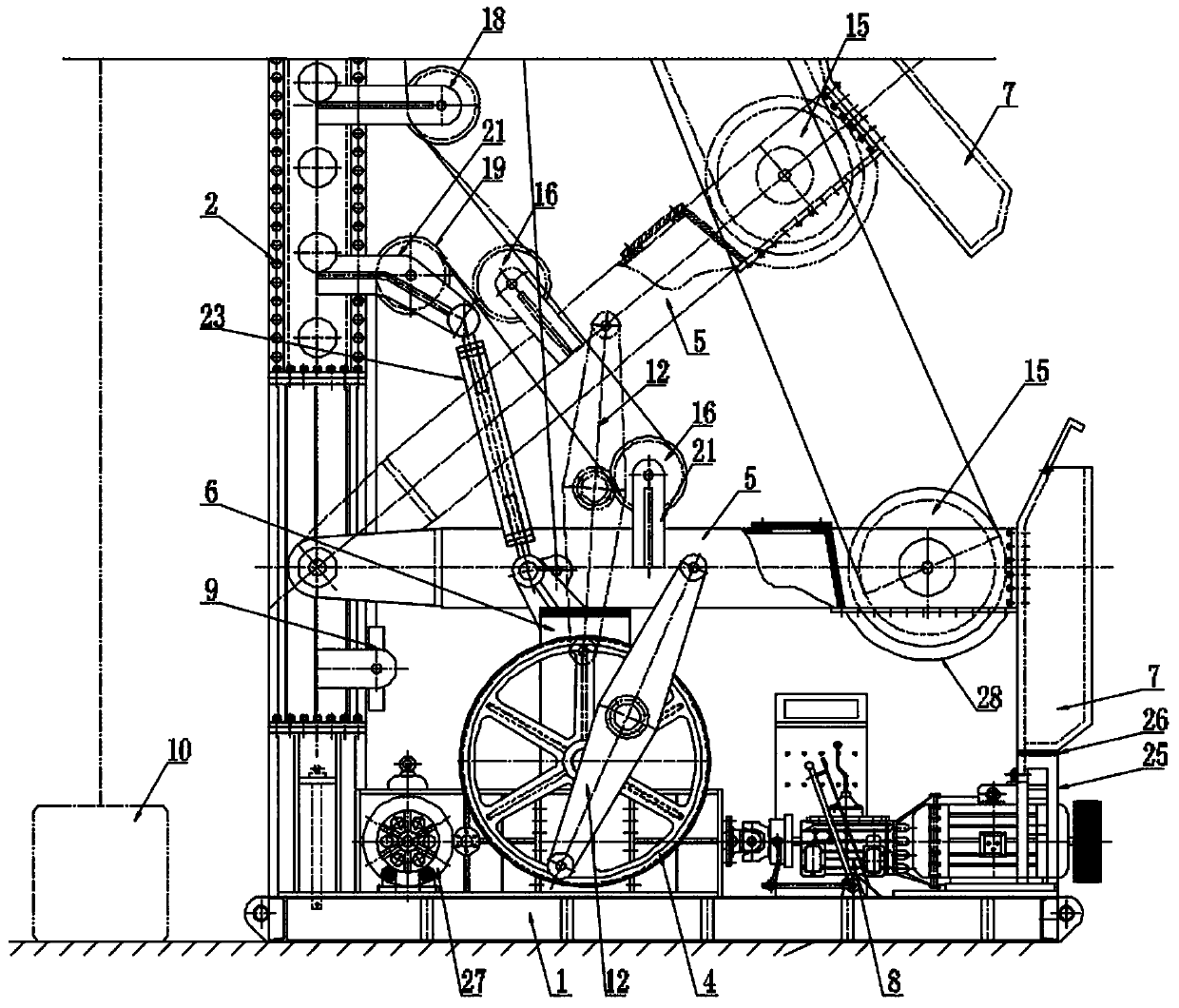

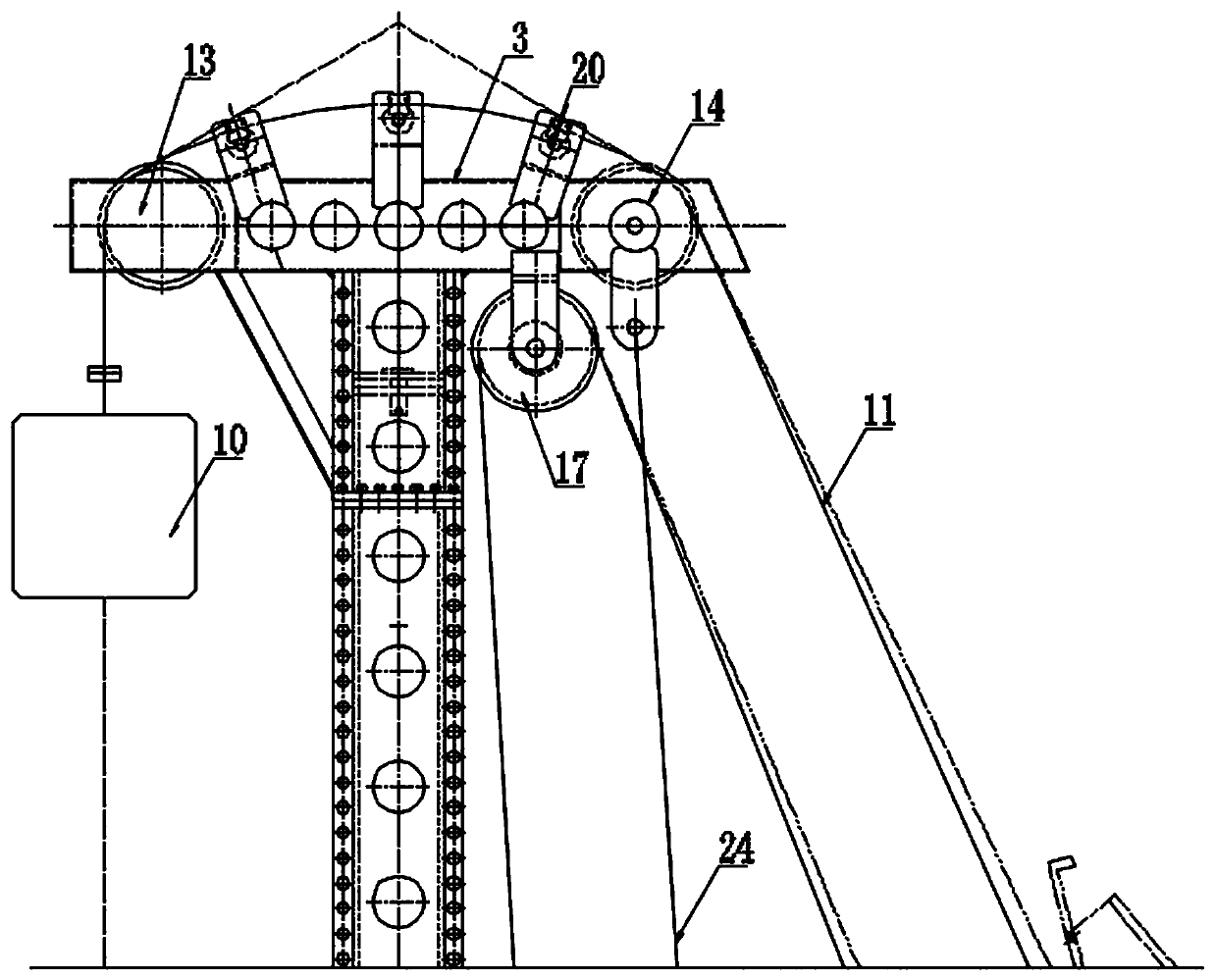

[0033] This embodiment discloses a rear swing angle pumping unit, which includes a base 1, a column 2, a boom 3, a power wheel 4, a driving mechanism 8, a swing arm 5, a support frame 6, a counterweight box 7, a rope drum, and a stable rope 9, rope hanger 10 and steel rope 11, the lower end of the column 2 is fixed on the base 1, the upper end is fixedly connected with the boom 3, one end of the swing arm 5 is movably connected to the column 2, and the other end is connected with the matching The heavy box 7 is fixedly connected; the support frame 6 and the driving mechanism 8 are fixed on the base 1, and the power wheel 4 is symmetrically fixed on both sides of the support frame 6 and driven by the drive mechanism 8; the power wheel 4 is connected eccentrically There is a connecting rod 12, one end of the connecting rod 12 is movably connected with the power wheel 4, and the other end is movably connected with the middle part of the swing arm 5, the rope stabilizer 9 is fixed ...

Embodiment 2

[0044] This embodiment discloses a rear swing angle pumping unit, which includes a base 1, a column 2, a boom 3, a power wheel 4, a driving mechanism 8, a swing arm 5, a support frame 6, a counterweight box 7, a rope drum, and a stable rope 9, rope hanger 10 and steel rope 11, the lower end of the column 2 is fixed on the base 1, the upper end is fixedly connected with the boom 3, one end of the swing arm 5 is movably connected to the column 2, and the other end is connected with the matching The heavy box 7 is fixedly connected; the support frame 6 and the driving mechanism 8 are fixed on the base 1, and the power wheel 4 is symmetrically fixed on both sides of the support frame 6 and driven by the drive mechanism 8; the power wheel 4 is connected eccentrically There is a connecting rod 12, one end of the connecting rod 12 is movably connected with the power wheel 4, and the other end is movably connected with the middle part of the swing arm 5, the rope stabilizer 9 is fixed ...

Embodiment 3

[0051] This embodiment discloses a rear swing angle pumping unit, which includes a base 1, a column 2, a boom 3, a power wheel 4, a driving mechanism 8, a swing arm 5, a support frame 6, a counterweight box 7, a rope drum, and a stable rope 9, rope hanger 10 and steel rope 11, the lower end of the column 2 is fixed on the base 1, the upper end is fixedly connected with the boom 3, one end of the swing arm 5 is movably connected to the column 2, and the other end is connected with the matching The heavy box 7 is fixedly connected; the support frame 6 and the driving mechanism 8 are fixed on the base 1, and the power wheel 4 is symmetrically fixed on both sides of the support frame 6 and driven by the drive mechanism 8; the power wheel 4 is connected eccentrically There is a connecting rod 12, one end of the connecting rod 12 is movably connected with the power wheel 4, and the other end is movably connected with the middle part of the swing arm 5, the rope stabilizer 9 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com