Steel-based bushing for pin shaft sleeving

A pin bushing and bushing technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of large friction loss, looseness, and easy sliding of pins, so as to reduce vibration and collision friction loss, improve Service life, firm effect of socket pin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific embodiments.

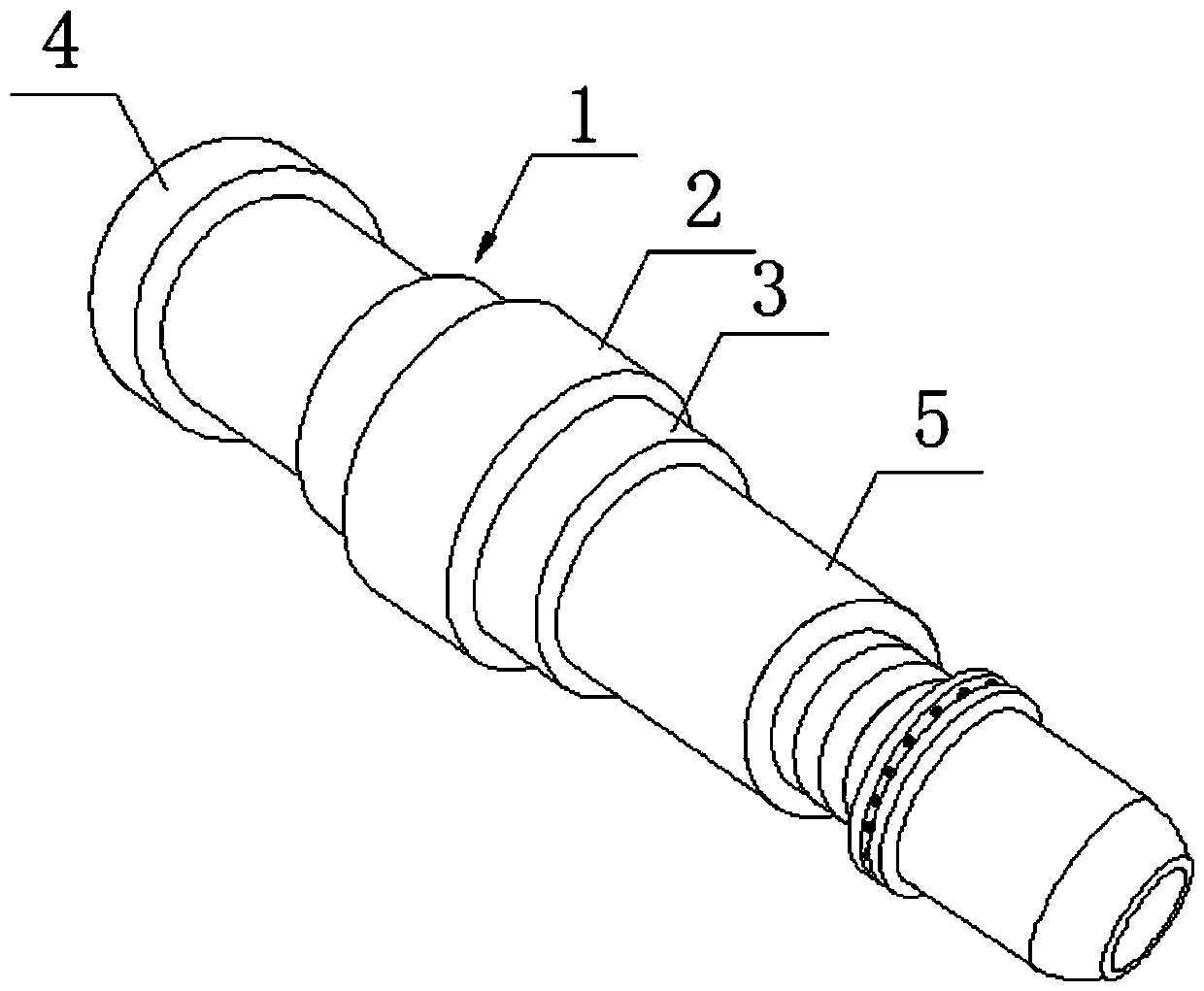

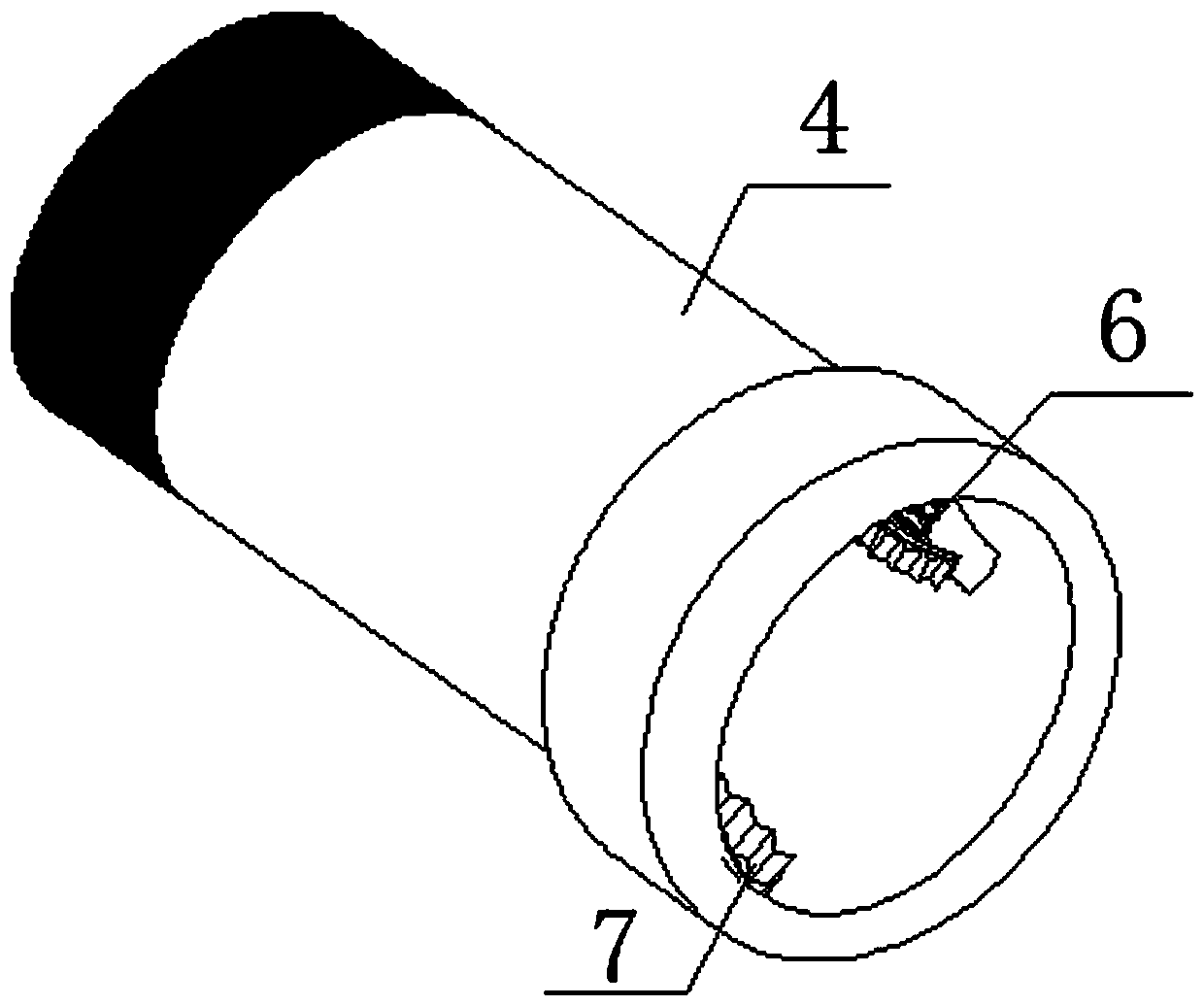

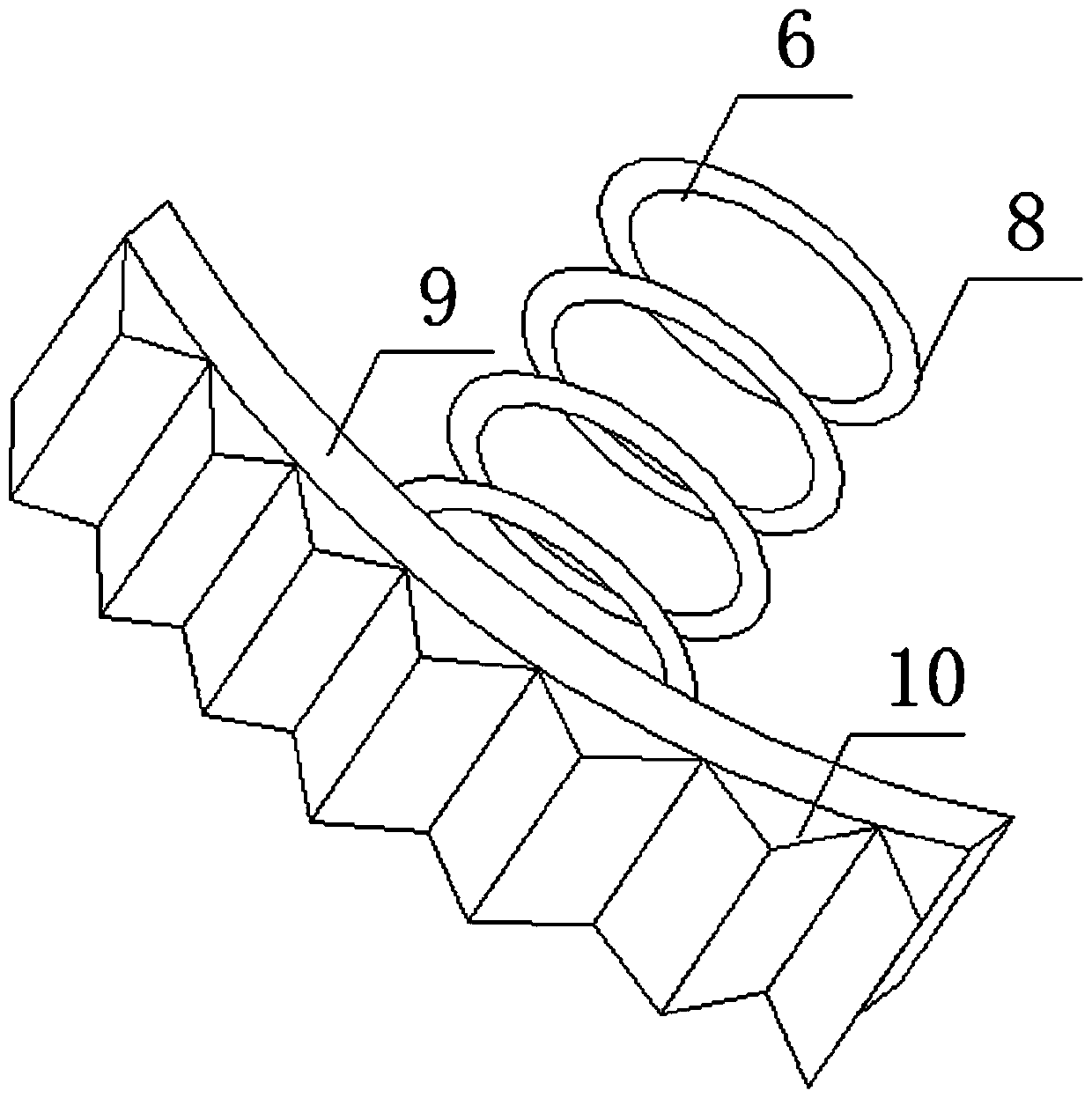

[0020] Such as Figure 1-5 As shown in the figure, a steel-based bushing for pin shaft socketing includes a bushing body 1, a sliding ring 2 and a telescopic front sleeve 5. The sliding ring 2 is installed in the middle of the bushing body 1, and the inside of the sliding ring 2 is A mounting ring 3 runs through, and a rear welding ring 4 is welded at one end of the mounting ring 3, and a first extrusion support frame 6 is arranged inside the rear welding ring 4, and a second extrusion support frame 7 is provided on one side of the first extrusion support frame 6, And the first extrusion frame 6 is provided with a spring 8, one end of the spring 8 is fixedly connected with a connecting plate 9, and several bumps 10 are welded on the connecting plate 9, and the telescopic front cover 5 is provided with a screw thread 11, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com