Water leakage protection device of electric ball valve

A technology of water leakage protection and electric ball valve, which is applied in the direction of valve device, valve operation/release device, valve details, etc. It can solve the problems of power failure, large initial rotation torque of ball valve, and failure of internal driver to drive ball valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

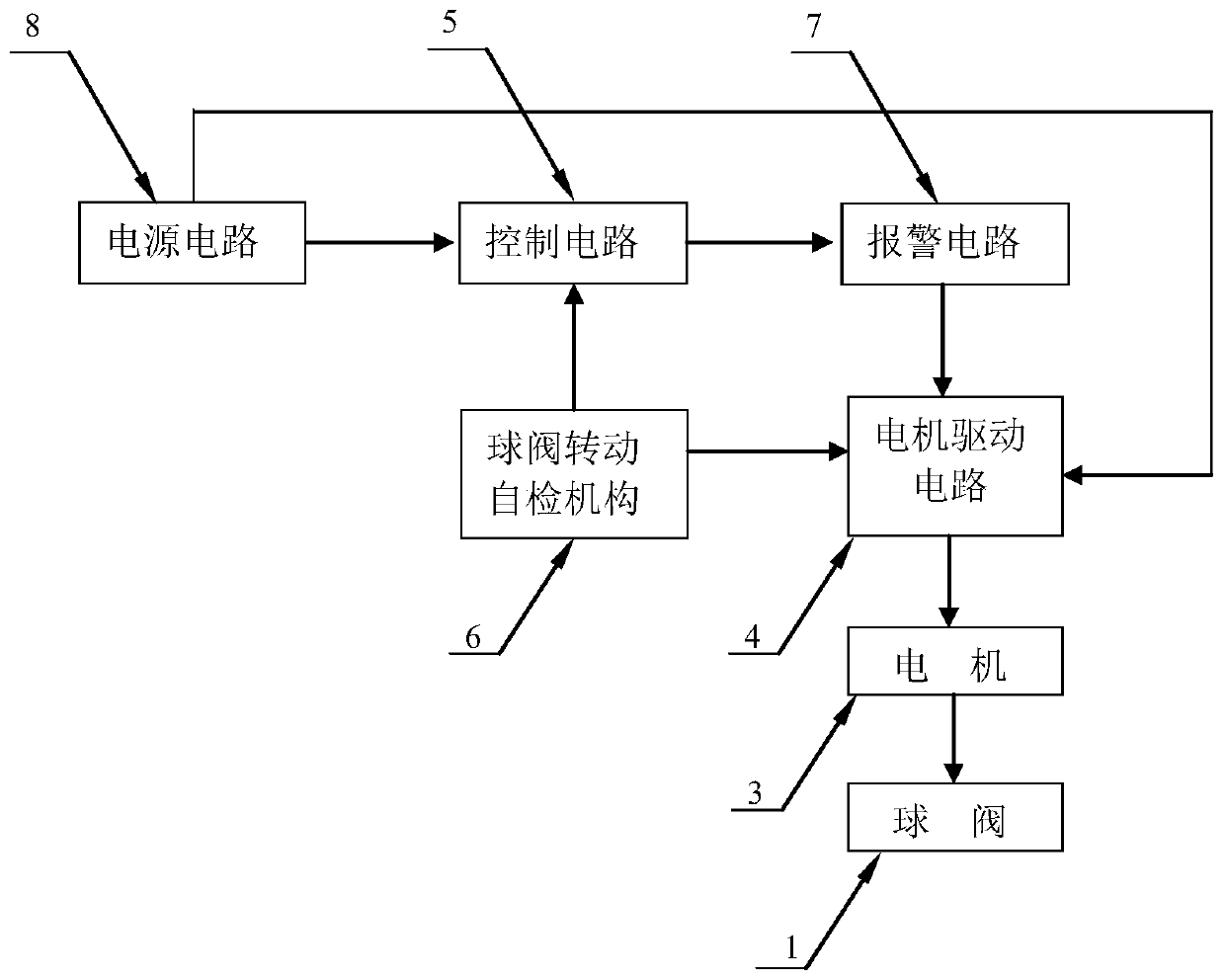

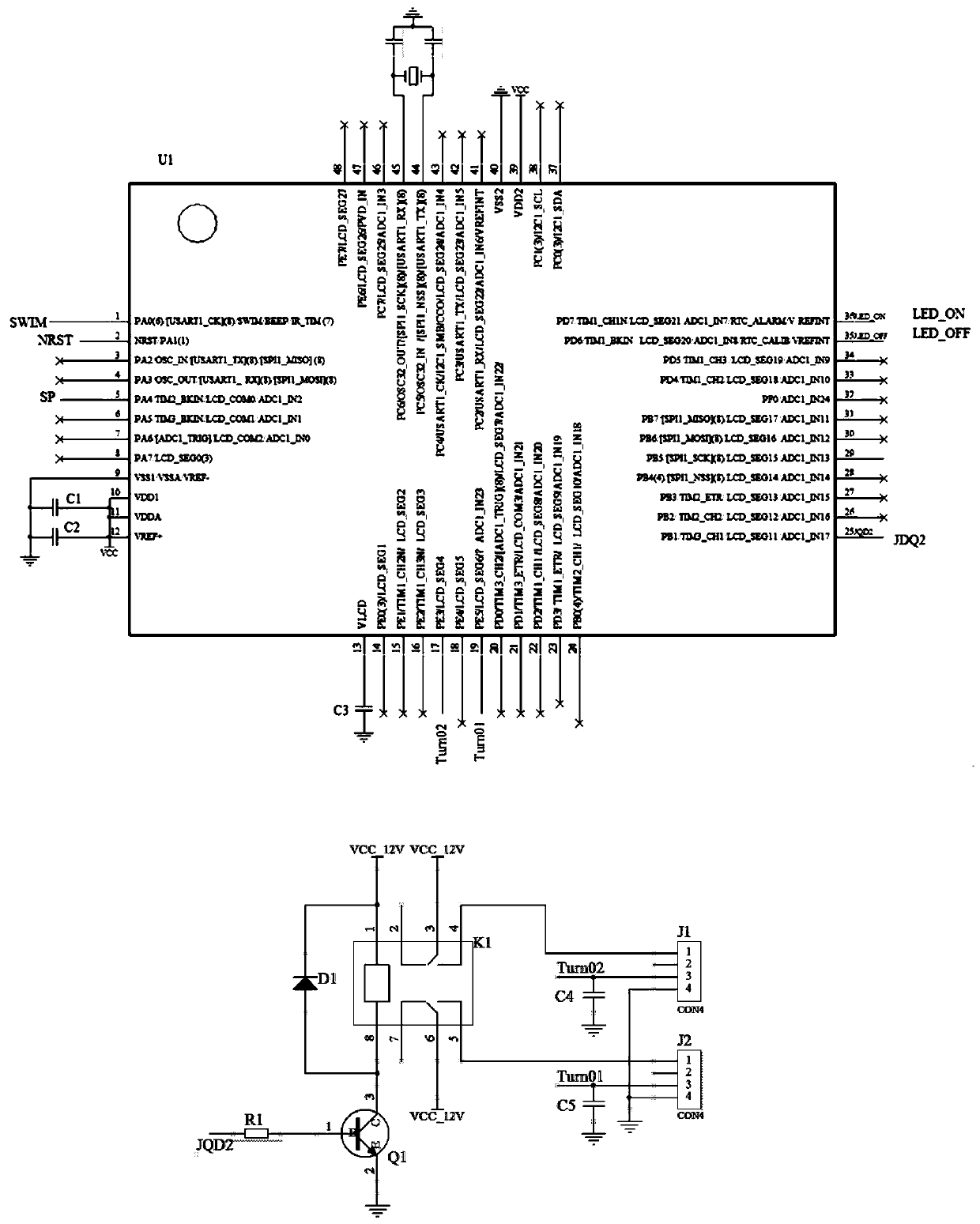

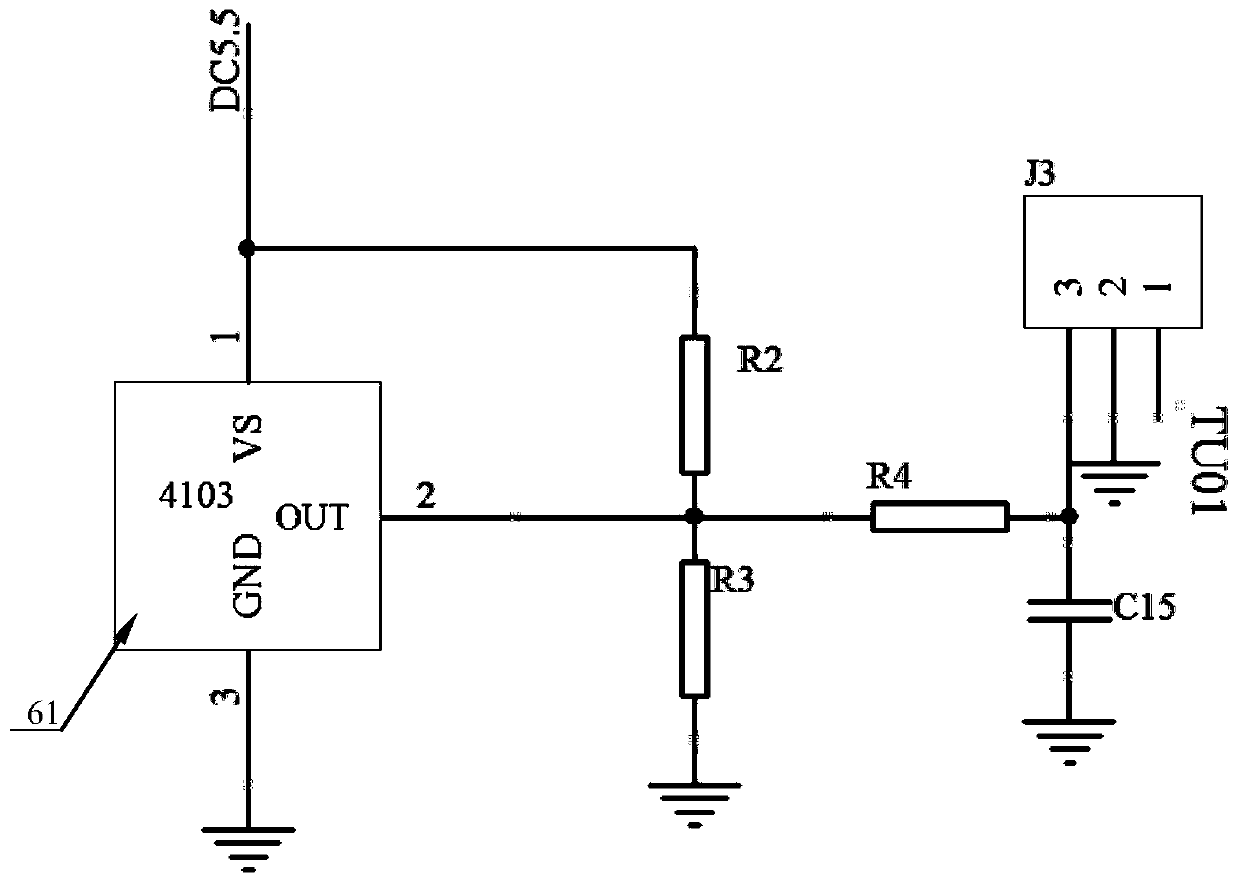

[0038] Example one: such as figure 1 As shown, a water leakage protection device for an electric ball valve includes a ball valve 1, a motor 3 for driving the switch of the ball valve 1, and a motor drive circuit 4 for driving the motor 3 forward and reverse, and also includes a control circuit 5 and a ball valve rotation self-check Mechanism 6, alarm circuit 7, and power supply circuit 8 for supplying power to the entire device. The control circuit 5 regularly controls the motor drive circuit 4 to drive the motor 3 to rotate in the forward or reverse direction. The ball valve rotation self-checking mechanism 6 is used to detect whether the ball valve 1 is rotating. It is normal, and the detected signal is fed back to the control circuit 5, and the alarm circuit 7 is connected to the control circuit 5. The control circuit 5 judges whether the alarm circuit 7 gives an alarm based on the signal fed back by the ball valve rotation self-checking mechanism 6.

[0039] In this specific ...

Embodiment 2

[0047] The second embodiment: the other structure is the same as that of the first embodiment, the difference lies in: Figure 8-13 As shown, the device also includes an upper housing 9 and a lower housing 10. A downwardly recessed motor mounting seat 101 is provided on one side of the lower bottom surface of the lower housing 10, the motor 3 is embedded in the motor mounting seat 101, and the ball valve 1 includes A mounting base plate 12 is fixedly connected to the other side of the lower housing 10. A plurality of columnar bodies 13 and reinforcing bosses 14 extending upward and downward are arranged on the lower bottom surface of the other side of the lower housing 10. The mounting base plate 12 is provided with a first limiting groove 151 that matches the column 13; the mounting base plate 12 is provided with a second limiting groove 152 that matches with the reinforcing boss 14, and the column 13 is provided with up and down through The upper mounting hole 16 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com