A bending sensor structure and method for pipeline deformation detection

A sensor and measurement method technology, applied in the field of bending sensors, can solve the problems that it is difficult to reflect the deformation state of the pipeline, cannot perform real-time monitoring, and the cost of optical fibers is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

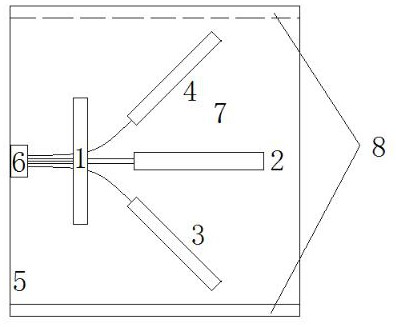

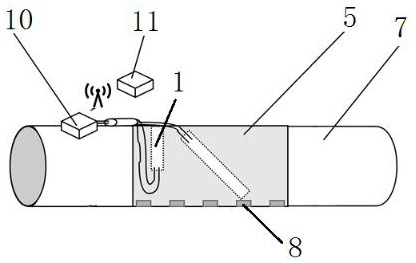

[0028] Such as figure 1 with figure 2 As shown, a bending sensor structure for pipeline deformation detection includes at least four bending sensors on the flexible film 5, the first bending sensor 1 is parallel to one edge of the flexible film, and the second bending sensor 2 is perpendicular to the first A bending sensor 1, the first bending sensor 1 and the second bending sensor 2 form a T-shape, the third bending sensor 3 and the fourth bending sensor 4 are respectively fixed at the two right angles of the T-shape, the first bending sensor 1. The output ends of the second bending sensor 2, the third bending sensor 3, and the fourth bending sensor 4 are electrically connected to the interface 6 respectively; the four bending sensors on the flexible film are directly printed on the flexible film 5 strain resistors. Fixing the third bending sensor 3 and the fourth bending sensor 4 at two right angles of the T shape is arranged by 30 degrees to 60 degrees, and its best angl...

Embodiment 2

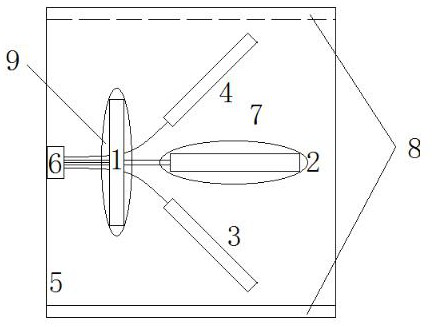

[0041] Such as image 3 As shown, a bending sensor structure for pipeline deformation detection includes at least four bending sensors on the flexible film 5, the first bending sensor 1 is parallel to one edge of the flexible film, and the second bending sensor 2 is perpendicular to the first A bending sensor 1, the first bending sensor 1 and the second bending sensor 2 form a T-shape, the third bending sensor 3 and the fourth bending sensor 4 are respectively fixed at the two right angles of the T-shape, the first bending sensor 1. The output ends of the second bending sensor 2, the third bending sensor 3, and the fourth bending sensor 4 are electrically connected to the interface 6 respectively; the first bending sensor 1 and the second bending sensor on the flexible film 2. The third bending sensor 3 and the fourth bending sensor 4 are independent bending sensors with the same performance fixed on the flexible film, the first bending sensor 1, the second bending sensor 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com