A chaos theory and integrated learning-based coal mining machine cutting height prediction system

A technology of chaos theory and integrated learning, applied in the field of signal processing, can solve problems such as low precision and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

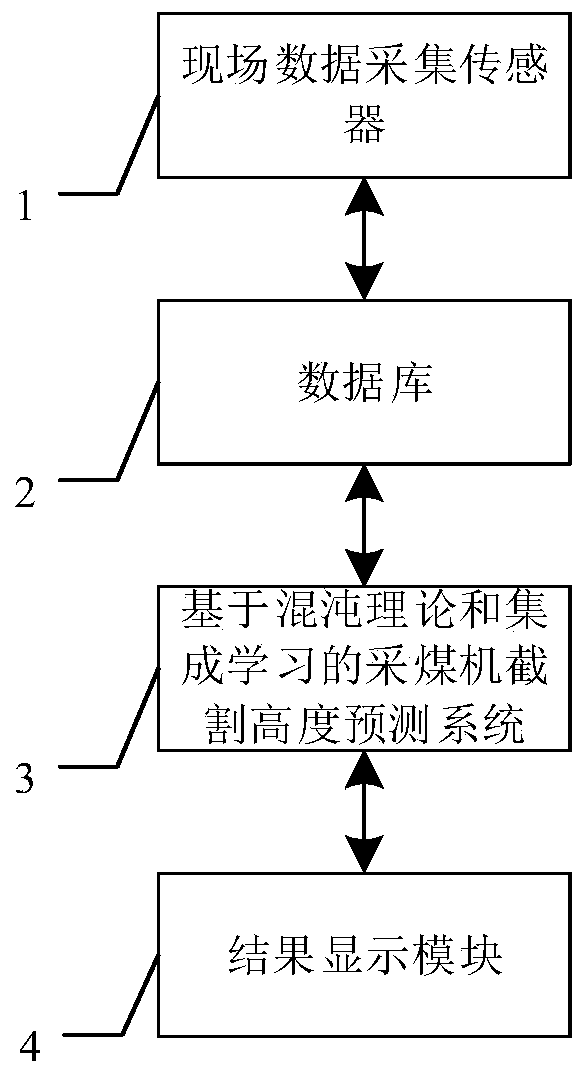

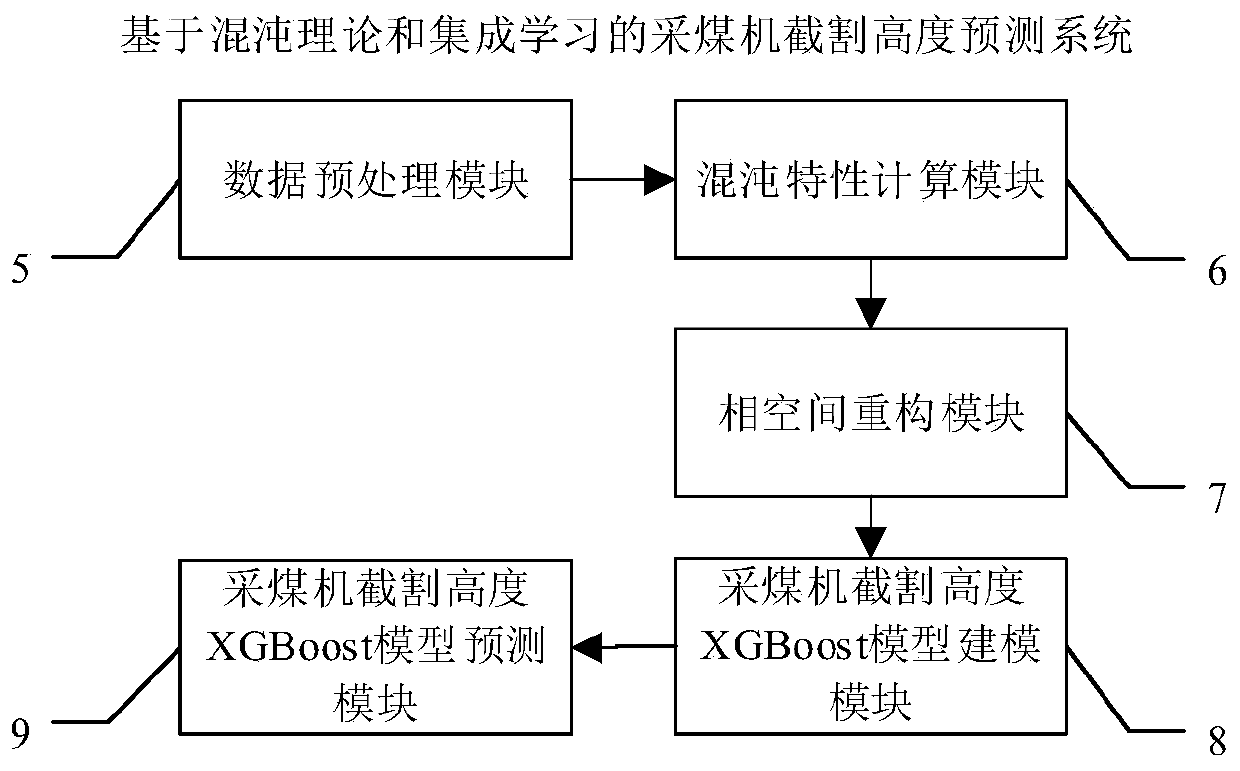

[0053] reference figure 1 , figure 2 , A shearer cutting height prediction system based on chaos theory and integrated learning, including data preprocessing module 5, chaotic characteristic calculation module 6, phase space reconstruction module 7, shearer cutting height limit gradient boosting (eXtreme Gradient Boosting , XGBoost) model modeling module 8 and shearer cutting height limit gradient boosting (eXtreme Gradient Boosting, XGBoost) model prediction module 9. The field data acquisition sensor 1, the database 2, the shearer cutting height prediction system based on chaos theory and integrated learning 3, and the result display module 4 are connected in sequence. The field data acquisition sensor 1 is connected to the historical cutting height of the shearer The signal is collected, and the data is stored in the database 2. The database 2 contains historical shearer cutting height data to provide data support for the shearer cutting height prediction system 3 based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com