Collar shaping space regulating and shaping device

A collar forming and forming device technology, applied in the direction of clothing, clothing, applications, etc., can solve the problems of inability to adjust the column and column width, enlarge the equipment volume, shrink, etc., to meet the needs, reduce the equipment volume, and improve the operating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

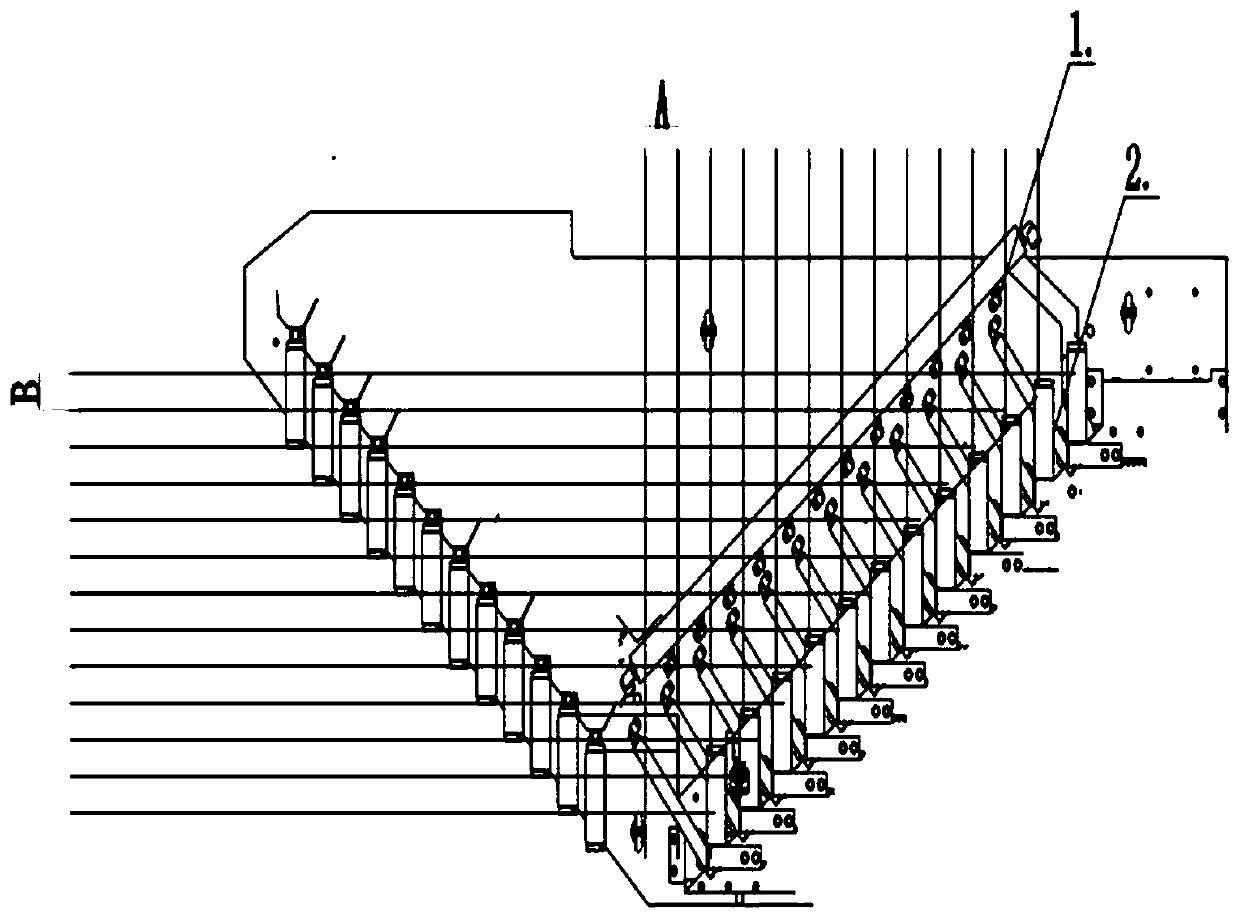

[0029] Such as figure 1 As shown, after the entire roll film of the collar forming device is cut, the row spacing is A, and it first enters the pneumatic levitation device 1 to complete the roll film turning, and here the pneumatic levitation device 1 is used to pass compressed air for suspension;

[0030] After the roll film passes through the column spacing adjustment device 2, it is turned over to realize the adjustment of the spacing between columns, and finally the column spacing A>column spacing B or column spacing A=column spacing B or column spacing A

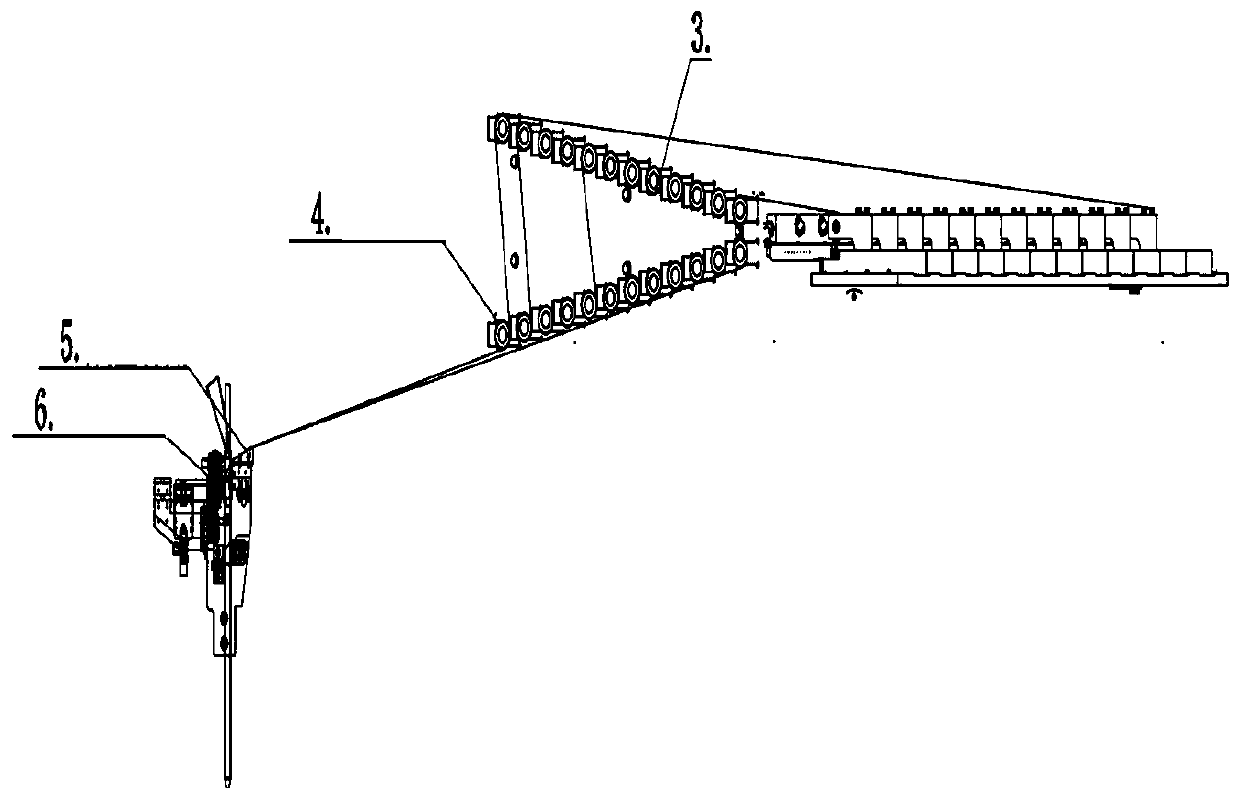

[0031] Such as figure 2 As shown, the roll film of the collar forming device is output by the column spacing adjustment device 2, and part of it enters the first roller group 3, and the other part enters the second roller group 4, so as to complete the lifting of the roll film of part of the collar forming device and the other part of the collar forming device The roll film is lowered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com